X-Ray Diffraction (XRD)

Home » Our Techniques » Spectroscopy » XRD

X-ray diffraction (XRD) is a powerful nondestructive technique for characterizing crystalline materials. It provides information on crystal structure, phase, preferred crystal orientation (texture) and other structural parameters, such as average grain size, crystallinity, strain and crystal defects. In addition, X-ray diffraction peaks are produced by constructive interference of a monochromatic beam of X-rays diffracted at specific angles from each set of lattice planes in a sample. The peak intensities are determined by the distribution of atoms within the lattice. Consequently, the X-ray diffraction pattern is the fingerprint of the periodic atomic arrangements in a given material. A search of the ICDD (International Centre for Diffraction Data) database of X-ray diffraction patterns enables the phase identification of a large variety of crystalline samples.

EAG’s multiple X-ray diffraction systems are equipped with optical modules that can be exchanged, depending on the analysis requirement, without affecting the accuracy of positioning. It is simple to change between line and point focus of the X-ray source, enabling simple switching from a regular XRD configuration to a high-resolution XRD configuration as needed.

Different combinations of optical modules enable the analysis of powders, coatings, thin films, slurries, fabricated parts or epitaxial films. EAG also has microdiffractometers with 2D area detectors for small spot (<50 µm) XRD, providing good signal-to-noise even with small X-ray beam sizes.

Main Applications of XRD Analysis

- Firstly, identification/quantification of crystalline phase

- Measurement of average crystallite size, strain or micro-strain effects in bulk materials and thin-film

- Quantification of preferred orientation (texture) in thin films, multi-layer stacks and manufactured parts

- Determination of the ratio of crystalline to amorphous material in bulk materials and thin-films

- Phase identification for a large variety of bulk and thin-film samples

- Detecting minor crystalline phases (at concentrations greater than ~1%)

- Determining crystallite size for polycrystalline films and materials

- Determining percentage of material in crystalline form versus amorphous

- Measuring sub-milligram loose powder or dried solution samples for phase identification

- Analyzing films as thin as 50 Å for texture and phase behaviors

- Determining strain and composition in epitaxial thin films

- Determining surface offcut in single crystal materials

- Lastly, measuring residual stress in bulk metals and ceramics

XRD Strengths

- Firstly, nondestructive

- Secondly, quantitative measurement of phase and texture orientation

- Thirdly, minimal or no sample preparation requirements

- Lastly, ambient conditions for all analysis

XRD Limitations

- Cannot identify amorphous materials

- No depth profile information

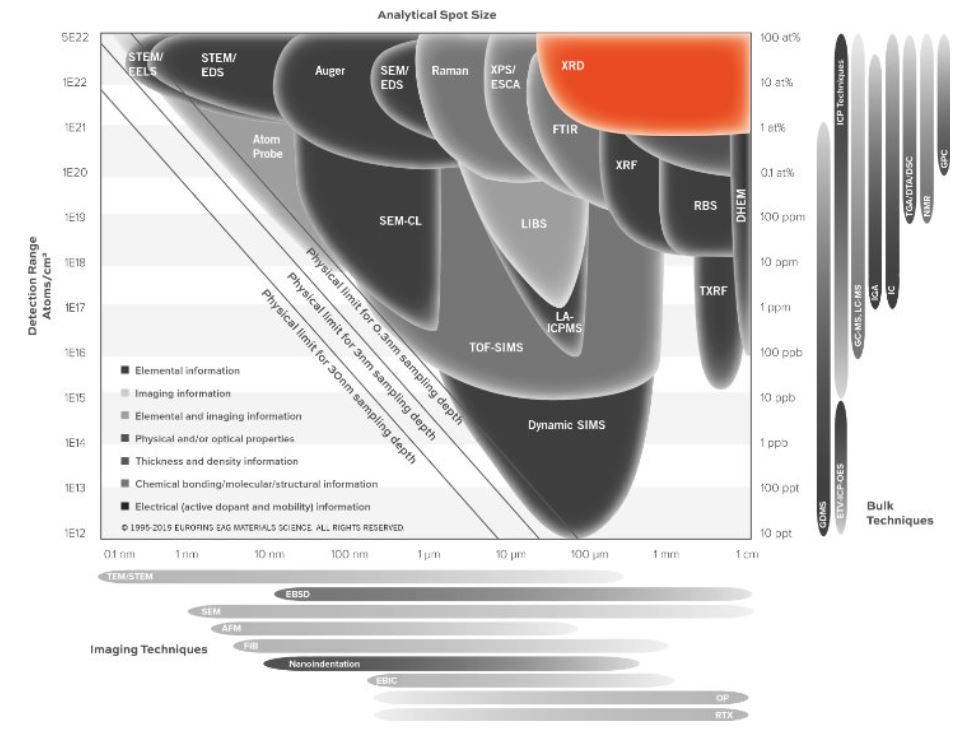

- Minimum spot size of ~25 µm

X-Ray Diffraction Technical Specifications

- Signal Detected: Diffracted X-rays

- Elements Detected: All elements, assuming they are present in a crystalline matrix

- Detection Limits: Quantitative multiphase analysis: ~1%

- Minimum film thickness for phase identification: ~20 Å

- Depth Resolution: Sampling depth between ~20 Å to ~30 µm, depending on material properties and X-ray incidence angle

- Imaging/Mapping: None

- Lateral Resolution/Probe Size: Point focus: 0.1 mm to 0.5 mm; Line focus 2 mm to 12 mm; Microdiffraction to ~20 µm

In addition, please read our application note, High Resolution X-Ray Diffraction (HR-XRD) Measurement of Compound Semiconductors, for a discussion of how this method may be used to determine composition and thickness of compound semiconductors such as SiGe, AlGaAs, InGaAs, and other materials.

In conclusion, EAG offers our customers XRD services to analyze many materials. Moreover, you can count on fast turnaround times, accurate data, and person-to-person service, ensuring you understand the information that you receive.

Would you like to learn more about using X-Ray Diffraction (XRD)?

Contact us today for your X-Ray Diffraction (XRD) needs. Please complete the form below to have an EAG expert contact you.