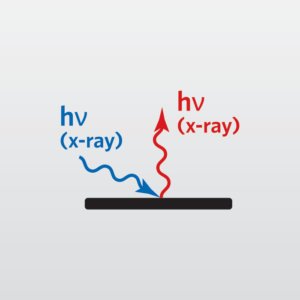

Total Reflection X-ray Fluorescence (TXRF)

Home » Our Techniques » Spectroscopy » TXRF

Total Reflection X-ray Fluorescence (TXRF) utilizes extremely low-angle X-ray excitation of a polished wafer surface to obtain the concentration of surface metallic contaminants.

The incident angle of the X-ray beam (typically 0.05-0.5°) is below the critical angle for the substrate and limits excitation to the outermost surface of the sample (~ top 80 Å, depending on the material). The fluorescence signal emitted from the sample is characteristic of the elemental contaminants present.

Surface Sensitivity

The surface sensitivity of TOF-SIMS makes it a good first pass at problem solving to give an overview of what types of species are present on a sample. Other techniques can then be used to obtain additional information. TOF-SIMS is also a technique that can detect species at significantly lower levels than traditional surface analysis techniques such as XPS and Auger.

A highly surface-sensitive technique, TXRF is optimized for analyzing surface metal contamination on semiconductor wafers such as Si, SiC, GaAs or sapphire.

Ideal Uses of Total Reflection X-ray Fluorescence

- Metallic surface contamination on semiconductor wafers

TXRF Strengths

- Trace element analysis

- Survey analysis

- Quantitative

- Non-destructive

- Automated analysis

- Whole wafer analysis (up to 300 mm)

- Can analyze many substrates, e.g. Si, SiC, GaAs, InP, sapphire, glass

TXRF Limitations

- Cannot detect low-Z elements (below Na on periodic chart)

- Polished surface required for best detection limits

TXRF Technical Specifications

- Signal Detected: Fluorescent x-rays from wafer surface

- Elements Detected: Na-U

- Detection Limits: 109 – 1012 at/cm2

- Depth Resolution: 30 – 80 Å (Sampling Depth)

- Imaging/Mapping: Optional

- Lateral Resolution/Probe Size: ~10 mm

Related Resources

Would you like to learn more about using TXRF?

Contact us today for your Total Reflection X-ray Fluorescence (TXRF) needs. Please complete the form below to have an EAG expert contact you.