Our Techniques

Home » Our Techniques

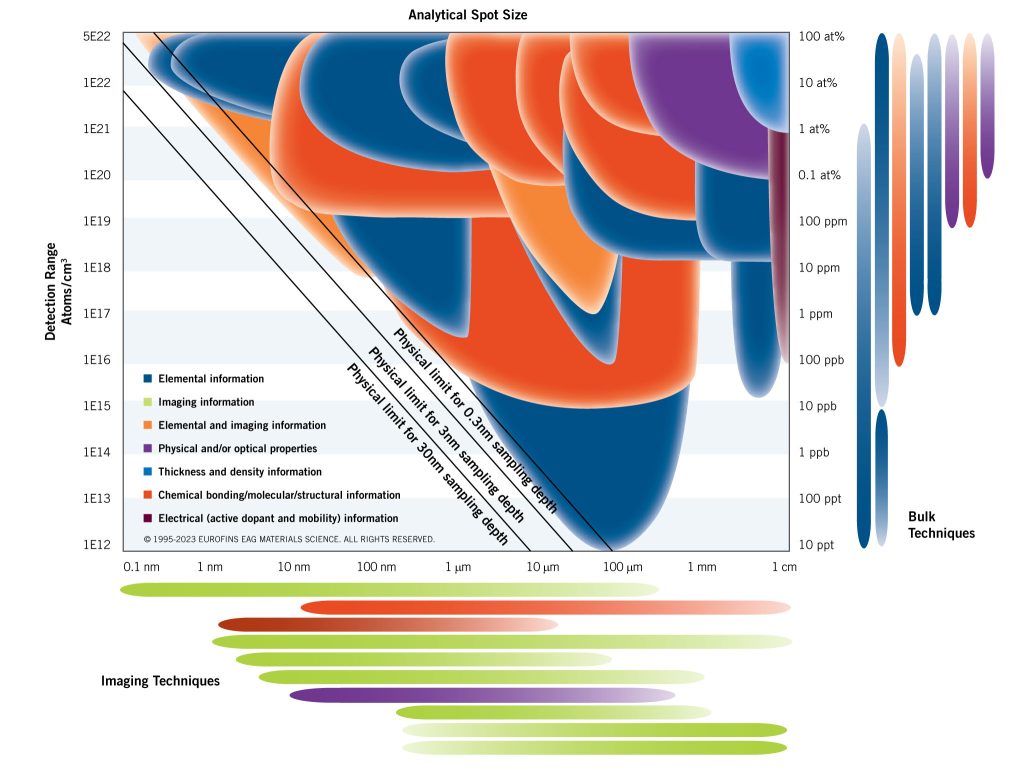

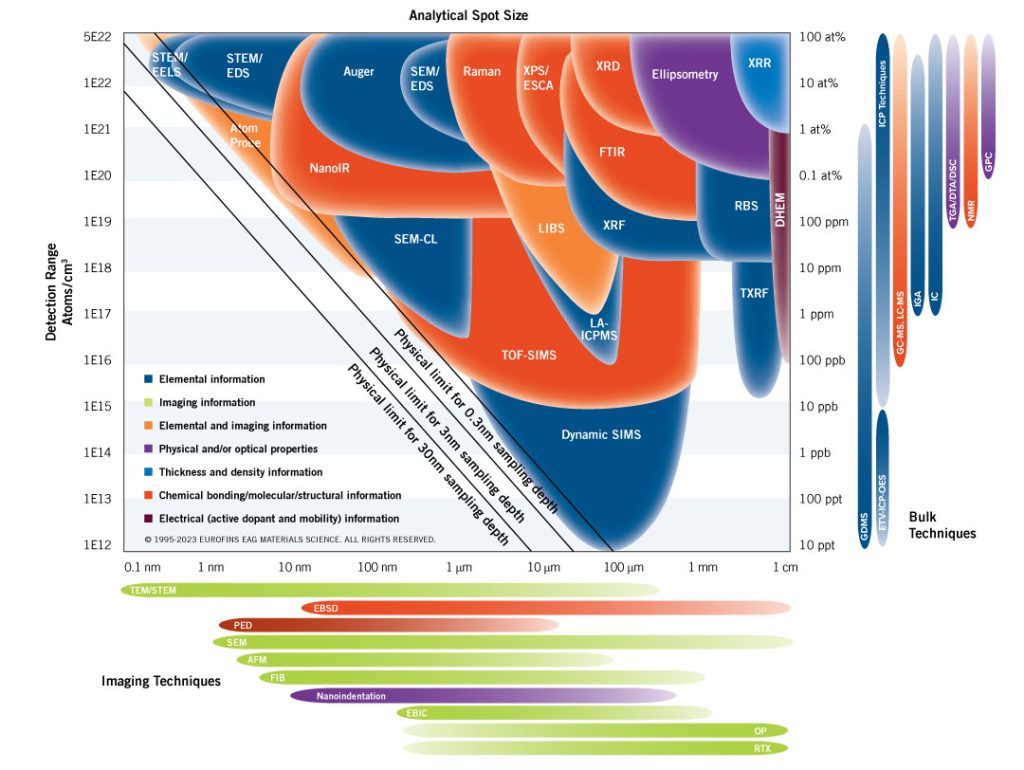

The EAG SMART (Spectroscopy and Microscopy Analytical Resolution Tool) Chart shown below offers a concise visual reference for comparing analytical techniques. Easily compare the detection limits and analytical resolutions of dozens of techniques used for materials characterization, evaluation surface analysis, purity surveys and more. Select a technique to learn more or contact an EAG Scientist. Download a printable version of this chart or view our SMART Chart Webinar series.

Scroll to the bottom of this page to view a list of all our in-house techniques.

/EELS

Nanometer scale elemental identification and mapping with TEM and STEM

/EDS

Elemental composition of small areas with a 1-2 nm range using STEM imaging

Quantitative elemental analysis of samples with small surface areas

/EDS

Elemental composition of small areas with a 0.1-3 μm range using SEM imaging

Ideal for qualitative analysis of organic, inorganic and mixed materials

/ESCA

Surface analysis technique to determine quantitative atomic composition and chemistry

Non-destructive technique for characterization of crystalline materials

Precise thin film thickness and optical constants measurements

Determination of thickness, interface roughness and density for thin films and multilayers

Quick identification of complex mixtures of materials and further characterization

Non-destructive elemental analysis for film thickness and composition measurements

Quantitative compositional thin film analysis without reference standards

H

E

M

Depth profiling for electrical properties including carrier concentration and mobility

Probe

3D atom map, element distribution and nanoscale structure characterization

NanoIR combines AFM with infrared spectroscopy

High-resolution digital cathodoluminescene (CL) images of luminescent materials

Characterize relative element abundances and element distribution in any solid sample

Surface microanalysis at ppm range and near complete characterization of materials

ICPMS

High precision elemental and stable isotope analysis of solid materials

Highly surface-sensitive technique for analyzing surface metal contamination

Unrivaled capabilities in SIMS analysis for dopant and impurity detection

Chemical analysis and characterization at the nano scale with great spatial resolution

Visualization of microstructure with spatial coordinates of crystalline samples

Provides visualization of material phase, crystal structure and stain level at nanometer (nm) scale

High-resolution surface topography images with elemental microanalysis and particle characterization

3D topographic imaging for surface roughness quantification and further characterization

High-resolution cross-section images of samples for SEM, STEM and TEM analysis

Mechanical characterization of highly-localized material properties

SEM-based technique for semiconductor failure analysis and device characterization

Surface topography characterization for a wide range of sample geometries and dimensions

Non-destructive, real time inspection of electronic components and metallurgical samples

D

M

S

Direct analysis of chemical composition and trace/ultra-trace level determinations

V

T

C

P

Quantitative chemical analysis with high sensitivity for a wide range of elements

C

High-throughput, versatile technique for charged molecule analysis

C

M

S

Identify and quantify organic compounds in mixtures with low detection limits

C

M

S

Identification, quantitation and mass analysis of materials in a complex matrix

G

A

Measure gas-forming elements (C, H, O, N and S) in solids from ppm to percentage levels

G

A

Thermal stability and degradation measurements from physical and chemical changes

S

C

Thermal analytical tool for best processing temperatures, sample composition and quality

M

R

Chemical structure and composition analysis with quantitative information

P

C

Characterization of polymers and other macromolecules in mixtures

Technique List

Would you like to learn more about our techniques?

Contact us today for your technical needs. Please complete the form below to have an EAG expert contact you.