Additive Manufacturing (3D Printing): Metallurgical and Material Services

Home » Additive Manufacturing (3D Printing): Metallurgical and Material Services

The progressive field of additive manufacturing (AM), also known as 3D printing, is transforming how products and parts are manufactured. AM is proving to be a more cost-effective solution than “traditional” subtractive manufacturing for applications where low production volumes, short turnaround times, complex part geometries, and/or high value materials are used.

IMPORTANCE OF METALLURGY DURING AM PART DEVELOPMENT

In order to achieve the desired mechanical properties with AM, the chemistry, microstructure and defects should be controlled. Process inputs such as feedstock quality, build chamber environment, scan strategy, part geometry and AM hardware all affect the thermal and physics interactions to determine the extent, size, and shape of defects and microstructure. These thermal and physics interactions can be explained similarly to welding process variables such as power, speed, beam interactions, heat transfer, and process temperature that determines solidification kinetics and subsequently phase distribution and grain morphology.

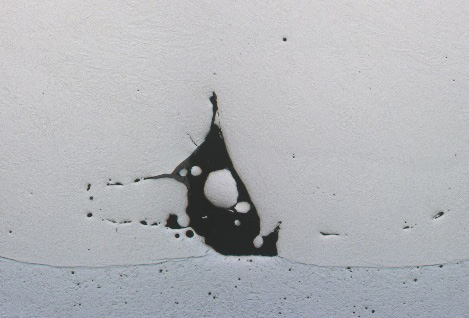

EAG can help determine what caused the defect or why the AM part does not meet the mechanical requirements. For example, in Laser Directed Energy Deposition (L-DED), it is known that porosity defects are related to flow rate of the fill gas and the path of the gas flow. Additionally, solidification rate and heat extraction influence residual stress leading to cracks in the L-DED parts. The scan strategy is known to highly influence the grain structure in the various types of Direct Energy Deposition (DED). Laser Powder Bed Fusion (L-PBF) is most sensitive and best at controlling microstructural evolution but keyhole porosity is a common defect. Some Electron Beam-Powder Bed Fusion (EB-PBF) systems can preheat the build volume to a high enough temperature for recrystallization, whereas L-PBF system may not have the capability. Post AM heat treatment is common to help optimize microstructure and thereby mechanical properties.

Would you like to learn more about Additive Manufacturing?

Contact us today for your additive manufacturing needs. Please complete the form below to have an EAG expert contact you.