Dynamic Mechanical Analysis (DMA)

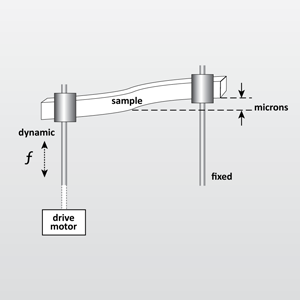

Dynamic Mechanical Analysis (DMA) is a technique used to characterize materials, specifically polymers. It applies a displacement to a sample and measures the mechanical response of the bulk material in a controlled temperature environment.

Dynamic mechanical analysis test conditions can be designed to study bulk mechanical properties of organic polymers to assist in determining key functional behavior related to:

Elasticity: Polymer resistance to permanent deformation due to resiliency of structure (recovery; stiffness)

Viscous Response: Deformation without breaking due to dissipation of mechanical energy by internal friction (damping)

DMA testing involves selection of the appropriate conditions of time, temperature, displacement and frequency to study the properties of interest. Some example selections are:

- Frequency sweep: frequencies can be specified to study the mechanical behavior of the sample as a function of oscillatory loading rate.

- Temperature ramp or isothermal temperature: precision heating and cooling allows the study of mechanical response as a function of temperature.

- Displacement modes:

- Tensile (stretch) for thin films and fibers

- Flexural (bend) for filled and crystalline polymers, thermoplastic polymers, thermosetting resins, elastomers.

- Controlled force / displacement: non-oscillatory test that measures mechanical response after applying instantaneous force or displacement distance.

- Creep/recovery test

- Stress relaxation test

- Force ramp (Young’s Modulus, linear modulus of elasticity) – “mini-tensile tester”

Examples of the various properties that can be measured through select test conditions:

- Storage Modulus

- Complex Modulus

- Loss Modulus

- Tan Delta

- Creep Compliance

- Storage/Loss Compliance

- Relaxation Modulus

- Sample Stiffness

- Stress/Strain

- Young’s/Linear Elastic Modulus

- Transition Temperatures (e.g. Tg)

- Secondary Transitions (e.g. β)

Ideal Uses of Dynamic Mechanical Analysis (DMA)

- Measuring glass transition temperature (Tg) of polymers, especially highly filled thermoplastics and rigid thermosets

- Determining temperature ranges where material properties change from hard/rigid to soft/rubbery; “viscoelastic spectrum” to use for process design

- Comparative failure analysis of plastics and thermosets

- Differences in elastic modulus before and after processing , post-curing or physical aging

- Detecting phase separation of polymer blends or copolymers

- Dimensional stability of parts at operating temperature and loading

- Damping capability of polymer: dissipation of energy through internal motion; toughness

- Time-Temperature Superpositioning (TTS): study the effect of changing frequency on temperature-induced changes in polymers

Strengths

- Small sample geometry

- Offers wide range of programmable frequencies, force and temperature parameters

- Two types of force alterations: oscillating and linear

- Programmable temperature: (1) heating and cooling ramps, (2) isothermal

Limitations

- Geometrically uniform test specimens

Examples: rectangular specimens with maximum dimensions L = 60 mm; W ≤ 15 mm; T = ≤ 5 mm - Films size range: rectangular specimens with max. dimensions L = 30 mm; W ≤ 8 mm; T ≤ 2mm; , also adaptive for analyzing small diameter flexible tubing (e.g. medical grade).

- Fiber size range: dimensions L = 30 mm; W = 5 denier; Dia. ≤ 0.8 mm

DMA Technical Specifications

- Temperature operation from -150 – 600°C

- Temperature ramp (Heating/Cooling) 0.1 – 10°C/minute

- Force Range: 0.0001 to 18 N

- Frequency Range: 0.01 – 200 Hz

- Dynamic Sample Deformation Range: ±0.5 to 10,000 micrometer

Would you like to learn more about using Dynamic Mechanical Analysis (DMA)?

Contact us today for your Dynamic Mechanical Analysis (DMA) needs. Please complete the form below to have an EAG expert contact you.