Optical Profilometry (OP)

Home » Our Techniques » Imaging » OP

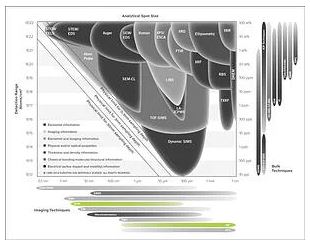

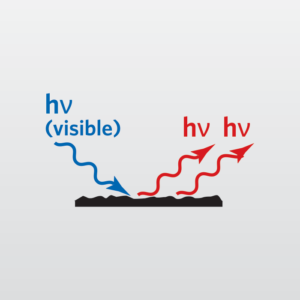

Optical profilometry (OP), also known as White Light Interferometry (WLI), is a non-contact interferometric-based method for characterizing surface topography. A typical optical profilometer analysis provides 2D and 3D images for surface analysis, numerous roughness statistics and feature dimensions. In addition to these standard measurements, EAG can also perform many advanced optical profilometry analyses with our state-of-the-art Bruker Contour GTX-8 3D and NPFlex optical instruments. These include:

- Analysis automation for high-throughput measurements of several hundred features on a single sample, such as patterned wafers or die features

- Thickness determination of transparent, continuous films

OP is suitable for numerous applications and sample types because it can accommodate many sample geometries, offering a wide range of possible analytical dimensions and a versatile Z-range, covering a broad range of potential surface roughnesses. EAG is committed to working with our clients to develop unique approaches for characterizing the topographies of even the most challenging samples with our 3D optical microscopy capabilities.

Ideal Uses of Optical Profilometry

- Step height and dimensional measurement

- Characterizing wear and friction of mechanical parts

- Determining consistency of solder bump heights, e.g. on flip chips and other advanced packaging

- Correlating roughness measurements with materials properties, e.g. adhesion, corrosion, appearance

- Measuring the radius of curvature of microfluidic channels, optics, etc.

- Assessing bow on coated/processed wafers, e.g. MEMS fabrication

- Quantifying thickness of continuous, transparent films (i.e. no physical step is needed)

- High-throughput screening of multiple features on a die or wafer

Strengths

- Firstly, wide range of possible analysis areas, feature heights and roughness statistics

- Secondly, it accommodates very large and very small sample sizes

- Thirdly, for non-destructive/non-contact applications

- Lastly, it is fast, and therefore good for multiple repeat measurements

Limitations

- Potential for optical artifacts on certain sample types

- Poor signal detection for very steep and rough surfaces

- Films must be transparent and of known refractive index for continuous film thickness measurements

Optical Profilometry Technical Specifications

- Lateral Resolution: 0.5 μm (best)

- Height Resolution: 0.01 nm (PSI) or 6 nm (VSI)

- Maximum feature height: 10 mm

- Minimum image size: 0.06×0.047 mm2

- Maximum image size: 2.2×1.1 mm2 (single image); 70×70 mm2 (stitched images)

- Maximum sample size: 300 mm diameter, 100 lbs weight, 4″/100 mm height

- Film Thickness: Between 150 µm and 2 µm thick

Would you like to learn more about using Optical Profilometry (OP)?

Contact us today for your Optical Profilometry (OP) needs. Please complete the form below to have an EAG expert contact you.