Cryogenic Transmission Electron Microscopy (Cryo-TEM)

Home » Our Techniques » Imaging » Cryo-TEM

Cryo-TEM involves performing Transmission Electron Microscopy TEM analysis while keeping the sample at cryogenic temperatures, i.e. -170°C (or 103 K).

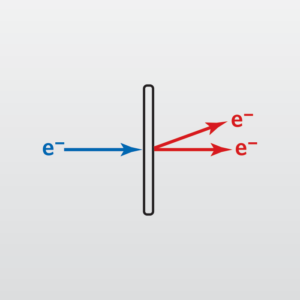

Transmission Electron Microscopy (TEM) is a technique that images a sample using an electron beam. High energy electrons (80-200 keV) are transmitted through electron transparent samples (~100 nm thick) and imaged on a plane.

The main reasons for the use of low temperature are

- The study of thin, frozen slices of suspensions, allowing for morphology studies of particles in their dispersed state.

- The reduction of sample heating by the electron beam and thus the reduction of potential beam damage of sensitive materials

- The study of low-temperature phases of crystalline materials

The production of thin (~100 nm) slices of frozen aqueous dispersions (‘vitrified ice layers’) is achieved using a Vitrobot ™ sample preparation tool, a dedicated cryo-sample-transfer unit and a cryo-TEM sample holder.

Ideal Uses of Cryo-TEM

- Colloidal dispersions of liposomes, polymersomes, emulsions

- Studies of particle clustering in the dispersion

- Electron-beam sensitive samples

- Low-temperature crystal phase studies

Strengths

- Allows for imaging of soft matter in its near natural state in an aqueous dispersion

- Allows for imaging of otherwise too beam sensitive materials

Limitations

- The sample preparation of aqueous dispersions requires method development for different sample types, as it is very dependent on the particle concentration, particle size and material viscosity

- The sample thickness of vitrified ice layers is determined by the particle size. The transparency of the sample thus sets a limit to the particle size at a few hundred nm

- The analysis time for Energy Dispersive X-ray Spectroscopy (EDS) analysis is limited because of beam-induced sublimation of the frozen water layer, even at cryogenic temperatures

Cryo-TEM Technical Specifications

- Signals Detected: Transmitted electrons

- Elements Detected: B-U (with EDS)

- Detection Limits: 1 at%

- Imaging/Mapping: Yes (with EDS)

Related Resources

Would you like to learn more about using Cryo-TEM?

Contact us today for your Cryo-TEM needs. Please complete the form below to have an EAG expert contact you.