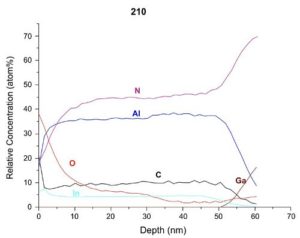

Analysis of CIGS Thin Film PV

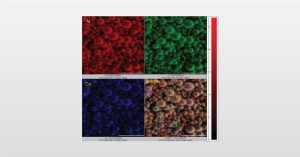

CIGS Thin Film PV performance reliability and uniformity as manufacturing is scaled up, can be optimized using materials characterization.

Home » XPS

CIGS Thin Film PV performance reliability and uniformity as manufacturing is scaled up, can be optimized using materials characterization.

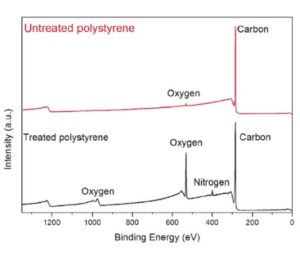

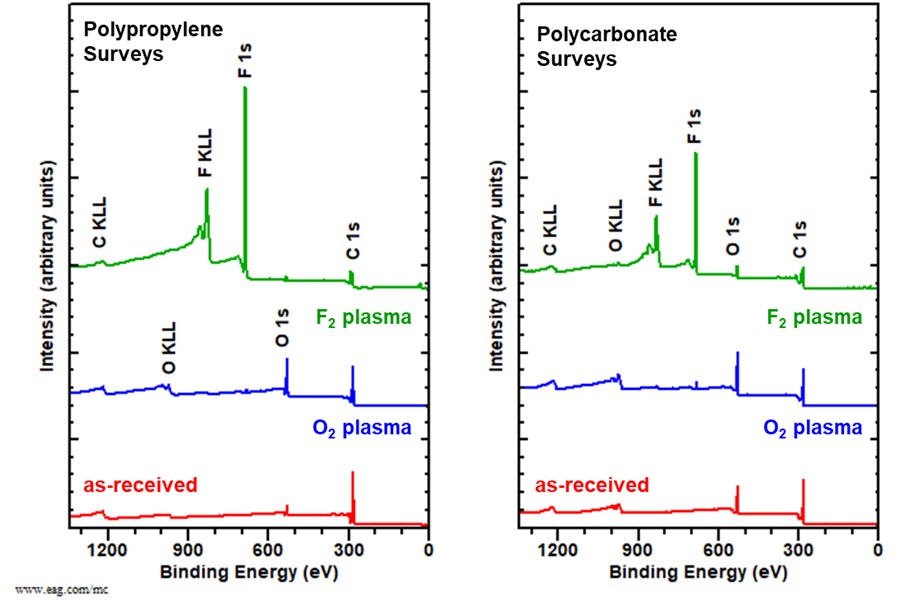

Surface chemistry affects multiple properties including adhesion, wettability, appearance and cleanliness. Auger, TOF-SIMS and XPS are often used to understand chemistry in the top few nanometers of a sample surface.

Atomic layer deposition analysis helps you meet ALD specifications for composition, thickness, and crystallinity.

Battery materials characterization services includes analysis of raw materials, surface chemistry, composition, morphology and uniformity

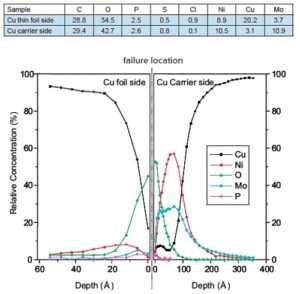

Laminate failure : Multi-layer laminate by analysis by XPS. Investigation details adhesive failure at a Ni2Mo-Cu interface due to monolayer contamination.

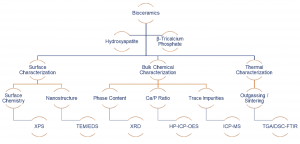

This paper will demonstrate how analytical tools can be used for the quality control of hydroxyapatite and β-tricalcium phosphate powders

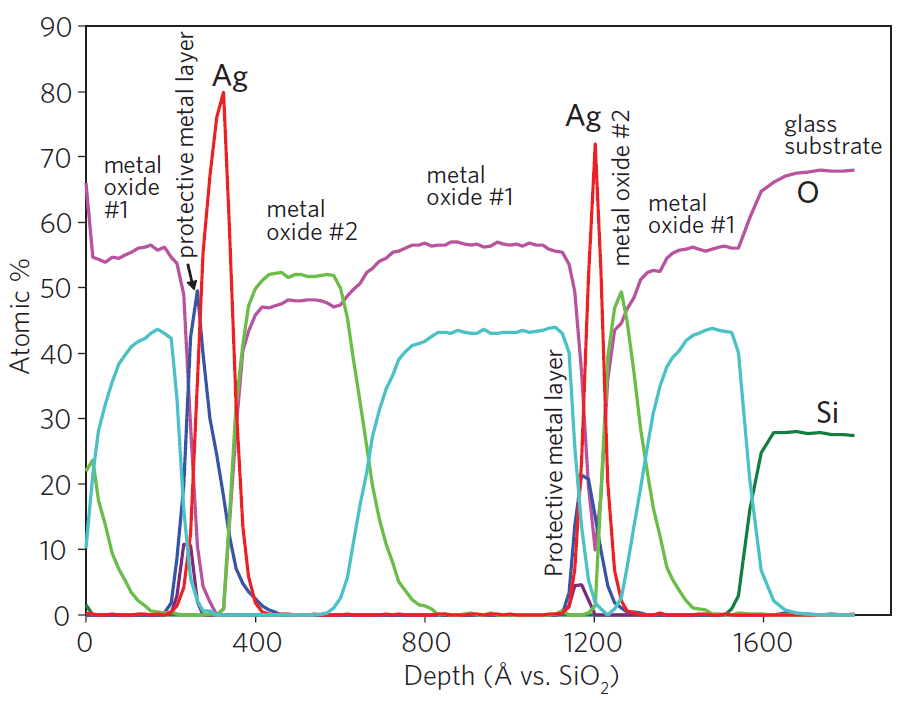

Investigation of the layer structure, identity and composition of an unknown coating system can be done in several ways.

November 2, 2023

Please join us for coffee and conversations! Enjoy a cup of coffee and pastries as you get to know our technical experts.

February 15, 2024

Please join us for coffee and conversations! Enjoy a cup of coffee and pastries as you get to know our technical experts.

May 15, 2024

Please join us for coffee and conversations! Enjoy a cup of coffee and pastries as you get to know our technical experts.

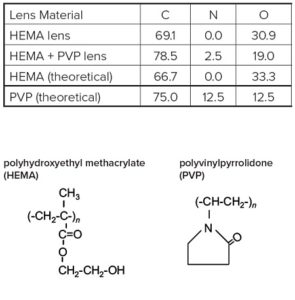

EAG Laboratories helps you understand contact lenses surface chemistry, critical to optimizing design and engineering optimal performance.

Essentials of Particulate Testing: USP <788> and AAMI TIR42 While there are many standards available for particulate testing, USP <788> and AAMI TIR42 are the

Eurofins EAG has a wide array of analytical techniques to verify the cleanliness of medical devices. We’ve helped our customers evaluate the cleanliness of their products using techniques including NVR analysis, often in combination with FTIR, XPS and TOF-SIMS.

The XPS surface analysis tool ensures evaluation of cleaning efficacy to monitor contamination efficiency.

Application of SIMS, XPS/ESCA, SEM and ICP-MS to test for appearance of glass lamellae in parenteral pharmaceutical solutions, by EAG

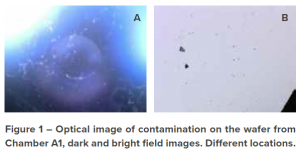

A concern with Stress testing of electronic devices is the potential contamination of devices by a poorly maintained or cleaned chamber.

ALD for semiconductors can produce films that are high in H, C, O and metals. XPS and SIMS depth profile analysis for composition & purity.

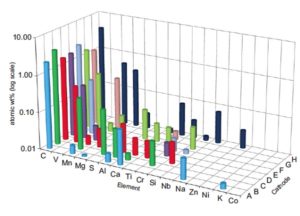

Battery characterization improves lithium-ion battery safety and performance using techniques such as SEM, TEM, XPS, GDMS, FTIR, ICP-OES, Raman and failure analysis

LED characterization, from process control to failure analysis to construction analysis, EAG Laboratories supports your LED analysis needs.

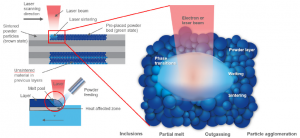

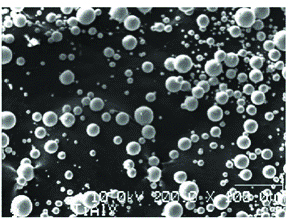

Additive manufacturing produces parts with geometric complexity, material composition gradient control, and lightweight structure design.

One of our surface analysis techniques, TOF-SIMS, can be used to characterize the surface coatings on screens and to compare the thickness of the coatings using depth profiles.

Particle analysis helps with black speck analysis, contamination identification, particulate analysis, identification of unknown materials.

The contact lens market has expanded beyond its original goal of vision correction to include products with decorative qualities.

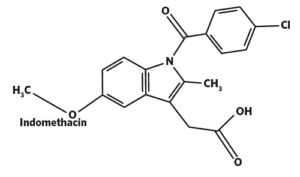

API Quantification on the Surface of Pharmaceuticals can be done by X-ray Photoelectron Spectroscopy (XPS) from EAG Laboratories.

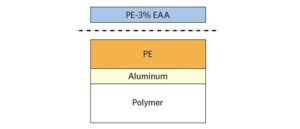

XPS and TOF-SIMS to solve adhesive failure of a polyethylene-ethylene acrylic acid (co-polymer) heat seal to polyethylene in a medical device.

Self-Assembled Monolayers (SAMs) are used in molecular recognition, surface engineering, micro-contact printing and molecular electronics.

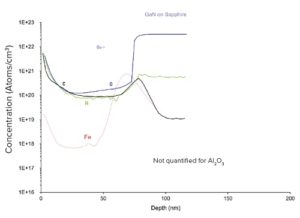

Silicon wafer solar cells and the analytical techniques used to investigate failures, bulk defects and other materials characterization.

Atomic Layer Deposition technology aids in the demand for computational advancement in the microelectronics industry.

May 6-10, 2024

Eurofins EAG Laboratories will be presenting “Thermal Oxide Characterization – Heat Treat Modality vs. Composition“ on May 10th. We hope to see you there!

Structural and Chemical Characterization of Li-ion Batteries help to understand why batteries fail leading to safer products and improvements.

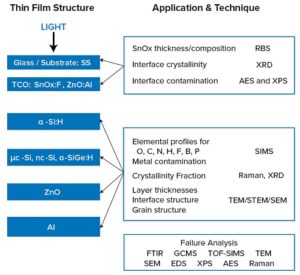

Surface analysis lab techniques on α-Si thin film PV, microcrystalline Si, nanocrystalline Si, amorphous SiGe, & microcrystalline SiC

For 3D printed products, XPS can provide composition and bonding information for the top 5-10nm sample surfaces. Oftentimes, surface contamination/oxide thickness would affect the appearance (as well as performance when applicable) of the material, and XPS could help identify the source and/or cause.

In this webinar we introduce analytical techniques used by EAG for surface analysis – XPS, Auger and TOF-SIMS

Analytical tools to understand chemical properties of polymers for adhesion, printability, barrier performance, appearance and strength

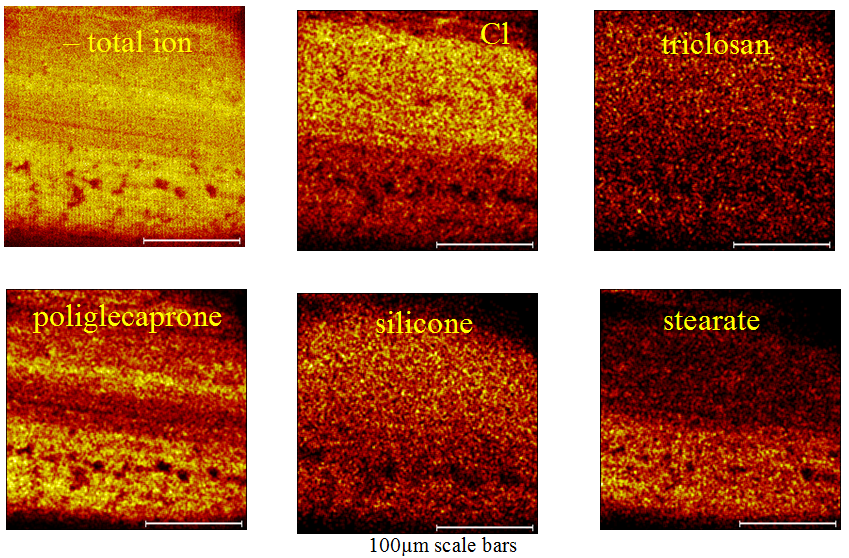

Antibacterial coated sutures reduce the occurrence of surgical site infections. Triclosan has been used in coatings on poliglecaprone.

Cold stage analysis has been shown to be effective for samples that are not solids at room temperature or that have components that are volatile in a vacuum system, such as the antibacterial coated sutures.

Measuring the chemical state of the battery components such as the cathode, anode, separator, electrolyte, contact layers and additives, at various stages of cycling, provides vital information about the electrochemical processes that occur during battery use.

Contamination control and defect reduction are critical issues in the manufacturing process of compound semiconductor devices which can impact the performance of the end product. We can provide valuable insights to identify contaminants and characterize materials throughout the product lifecycle.

EAG Laboratories can test for ionic or covalent bonds at our Sunnyvale, St. Louis, Minneapolis and Eindhoven facilities

PCOR-SIMS was originally developed to analyze Silicon Germanium (SiGe) devices for the communications industry.

There is still so much to learn about batteries, including challenges such as energy density, cycle life, fast charge, and safety. In this blog, we’ll be focusing on energy density.

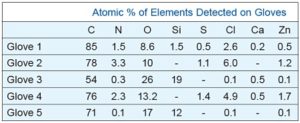

XPS Analysis of Disposable Gloves assesses materials exposed during product manufacturing to make sure contamination is not introduced.

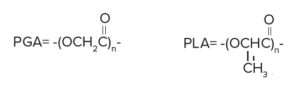

Polymer materials are in medical devices, automobiles, electronics, food packaging and in a wide range of industrial and consumer products.

XPS Analysis for sputter etching polymers and other organic materials to provide chemical characterization and depth profiling

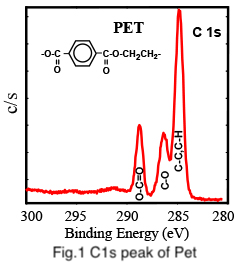

XPS (X-ray photoelectron spectroscopy) is capable of qualitative and quantitative analysis, and it can also determine chemical states.

XPS shows the species present can be determined or estimated from the measured chemical shift of the binding energy of each element

In this webinar we introduce X-Ray Photoelectron Spectroscopy (XPS) which is a surface analysis technique.

To enable certain features and improve your experience with us, this site stores cookies on your computer. Please click Continue to provide your authorization and permanently remove this message.

To find out more, please see our privacy policy.