A Deep Dive into Dynamic SIMS vs. static-SIMS

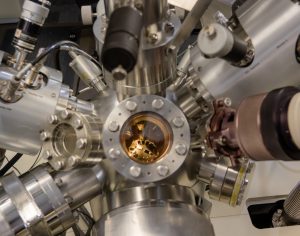

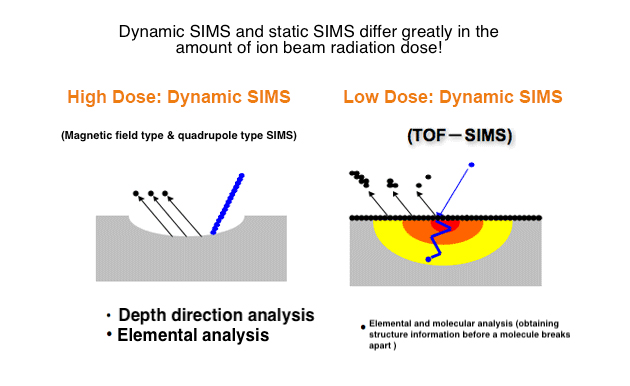

Different types of SIMS analyses exist. The two main types include Dynamic SIMS (high current) and static-SIMS (low current).

Home » SIMS

Different types of SIMS analyses exist. The two main types include Dynamic SIMS (high current) and static-SIMS (low current).

Electrochromic Glass, also known as smart glass, is a newer technology which allows users to turn glass opaque when needed, and clear when not.

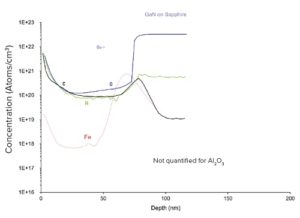

Gallium oxide has the potential to replace or substitute gallium nitride for power conversion in electric trains and vehicles.

Aerospace Materials Testing for Tunnel Junction Solar Cells Science has opened many doors in its advancement over the centuries.

Alkali contamination can compromise performance of oxide and other dielectric layers in electronic devices.

Televisions, computer screens, cell phone screens etc. are getting clearer, sharper, brighter and use much less power. This is all possible through LEDs.

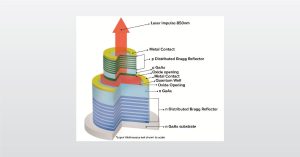

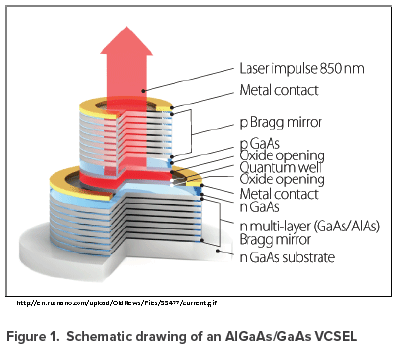

In the full webinar we will introduce analyzing VCSELs with a focus on secondary ion mass spectrometry (SIMS)

In the full webinar we answer pre-submitted questions from our audience about Secondary Ion Mass Spectrometry

February 12, 2025

During this live Ask the Expert event, we will answer pre-submitted questions from our audience regarding Silicon Carbide for High Powered Electronics. EAG Laboratories has a vast depth of experience analyzing silicon carbide using both bulk and spatially resolved analytic techniques and is the world-leading materials characterization and engineering resource for semiconductor testing.

Demand for compound semiconductors has rapidly grown recently. During this live event we answered questions surrounding the Materials Characterization of GaN HEMT power transistors.

Atomic layer deposition analysis helps you meet ALD specifications for composition, thickness, and crystallinity.

Surface Aluminum Characterization highlights advantages of using SurfaceSIMS.XP to determine contamination on processed Si wafers.

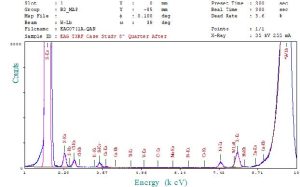

To identify and quantify contaminants, utilizing both TXRF and SurfaceSIMS.XP provides surface measurements on semiconductor surfaces.

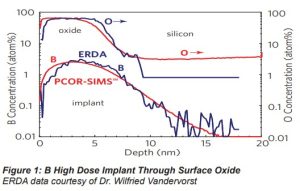

EAG’s PCOR-SIMS methodology includes point-to-point correction resulting in the most accurate SIMS profiling yet for ultra shallow implants.

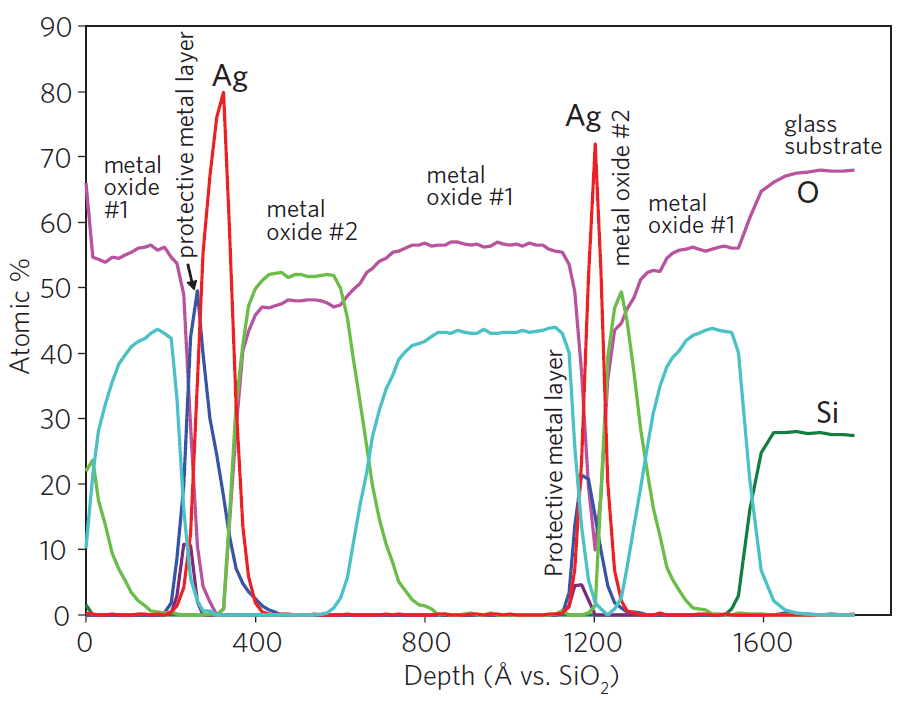

Investigation of the layer structure, identity and composition of an unknown coating system can be done in several ways.

May 15, 2024

Please join us for coffee and conversations! Enjoy a cup of coffee and pastries as you get to know our technical experts.

Glass development and glass product verification requires the measurement of composition with high accuracy.

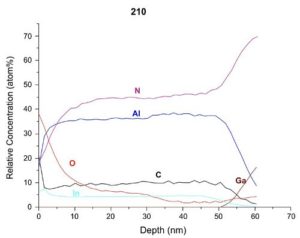

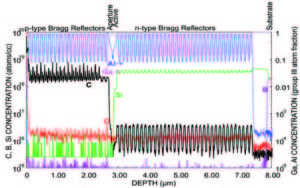

SIMS depth profile characterization provides accurate quantification for all measured species and matrix using our unique reference materials

25th May 2023

Eurofins EAG Laboratories tackled the problem of quantification of both major and minor elements in nonuniform, multi-element matrices with continuously graded composition changes using Point-by-point CORrected-SIMS.

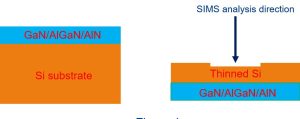

III-V materials partially provide us with the ever evolving and changing technological advances we enjoy today.

For over 40 years, EAG has been involved in the entire glass value chain, from raw starting materials to final products.

Application of SIMS, XPS/ESCA, SEM and ICP-MS to test for appearance of glass lamellae in parenteral pharmaceutical solutions, by EAG

Measurement of dopant & impurity concentrations in compound semiconductors by SIMS with low detection limits & excellent depth resolution.

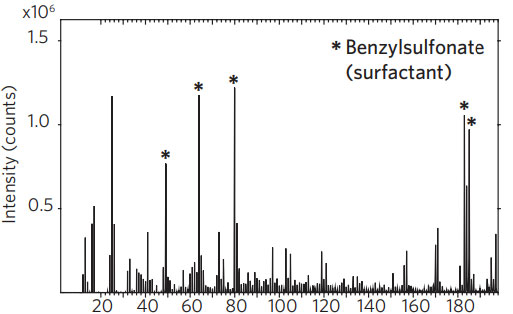

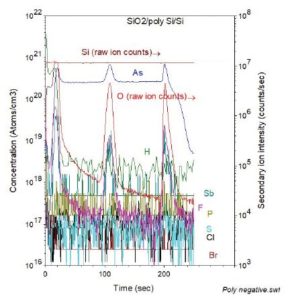

Uncover the invisible architecture of semiconductors with depth profiling using ion-TOF SIMS. This advanced technique reveals layer-by-layer composition in materials like silicon, GaN, and SiC. Learn how Eurofins EAG Laboratories supports your analysis with state-of-the-art tools and world class expertise.

ALD for semiconductors can produce films that are high in H, C, O and metals. XPS and SIMS depth profile analysis for composition & purity.

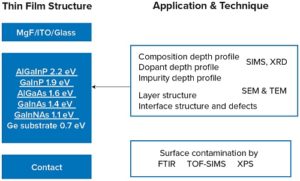

III-V solar cell technology for concentrator PV systems is the focus of this app note, illustrating the way that surface analysis can help

SIMS analysis is used to measure trace impurities in various materials such as semiconductors, metal, and insulating materials

Ion-exchanged glass is used in a variety of applications where strength, durability, and resistance to damage are important. Applications like smartphone screens.

LED characterization, from process control to failure analysis to construction analysis, EAG Laboratories supports your LED analysis needs.

EAG’s material and microelectronic testing service is dedicated to providing the best information from ensuring the purity of starting materials, to prototype testing of devices in the ramp up towards full-scale production.

28th September 2022

As ion implantation technology for semiconductors evolved, new metrologies to help its progress needed to be developed in parallel. Some of the current metrologies owe their present sophistication to this evolution.

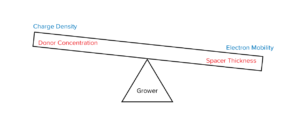

pHEMT device analysis by SIMS improves device performance and aids in failure analysis of III-V high-speed transistor structures.

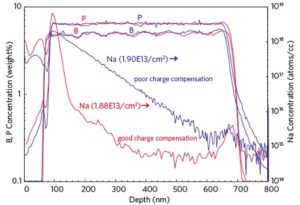

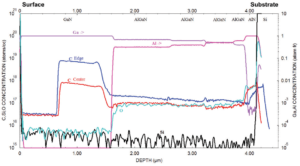

Point-by-Point Corrected SIMS (PCOR-SIMS) can determine accurate concentrations of matrix elements and dopants in GaN HEMTs.

Measure layer thickness, composition, and doping profiles more accurately than regular SIMS analysis.

PCOR-SIMS is an EAG proprietary technique that can measure layer thickness, composition, and doping profiles.

Quantum computing has the potential to revolutionize various fields by solving problems that are currently intractable for classical computers.

When information is required from a compound seminconductor, EAG can depackage and deprocess the sample, & fully characterize it.

Impurities adversely affect performance of a CIGS solar cell, with varying concentrations – SIMS can help measure representative sampling.

An advanced form of SIMS, PCOR-SIMS identifies dopants, impurities, compositions and thicknesses in various layers of VCSELs

SIMS services from EAG is featured in this technique note, including sample data, showing how SIMS detects low concentrations of impurities

SIMS tutorial from EAG Laboratories includes SIMS primary ion sources, ion energy analyzers, Sputtering and elemental effects

Survey-SIMS Depth Profiles analyze for dopants & impurities in a material without having prior knowledge in the structure being evaluated.

Silicon wafer solar cells and the analytical techniques used to investigate failures, bulk defects and other materials characterization.

SIMS detects very low concentrations of dopants and impurities. It has been used to study the diffusion of Al and Ga.

EAG’s SIMS Analysis Individual SiC Particles using a special sample preparation technique eliminates contributions from surface contamination

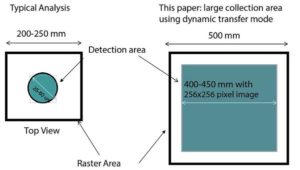

Raster change technique is used for SIMS measurement of very low levels of nitrogen in Silicon carbide by EAG Laboratories.

Secondary ion mass spectra measured by SIMS may not always provide information from the target element alone.

Compound semiconductors are responsible for the explosive growth of high-speed electronics, especially in communication applications and advanced mobile appliances.

Atomic Layer Deposition technology aids in the demand for computational advancement in the microelectronics industry.

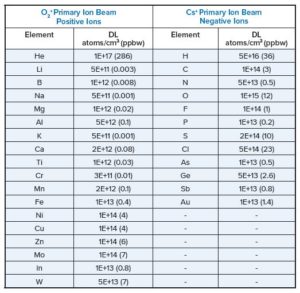

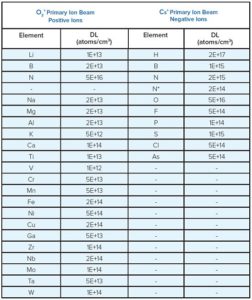

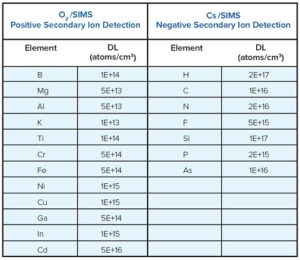

SIMS Detection Limits OF Selected Elements in GaAs, with detection levels are for normal depth profiling conditions of blanket wafers.

SIMS Detection Limits of Selected Elements in GaN. Normal depth profiling conditions, blanket wafers. Detection levels depends on area.

SIMS analytical technique typical detection limits for impurities in a HgCdTe matrix for normal depth profiling conditions.

SIMS Detection Limits of Selected Elements in InP for impurities in InP matrices with normal depth profiling conditions.

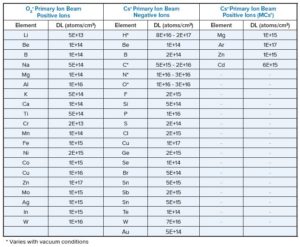

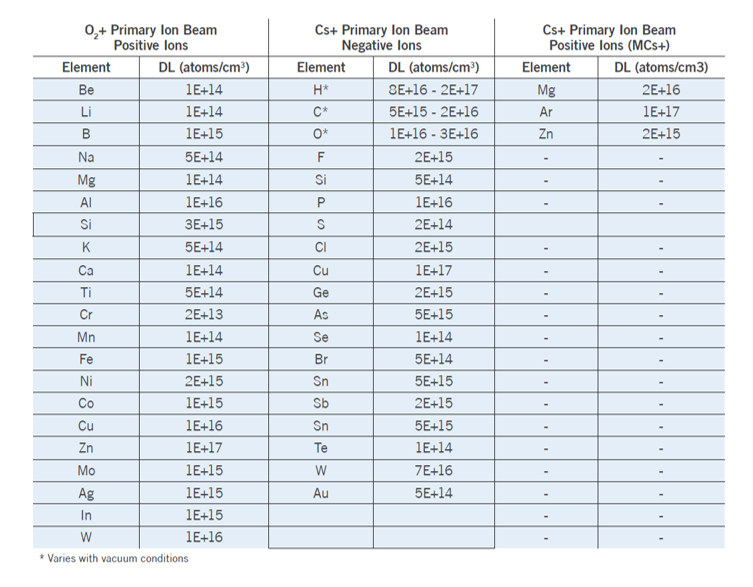

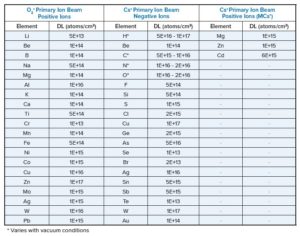

SIMS Detection Limits of Selected Elements in Si and SiO2 Under Normal Depth Profiling Conditions SIMS is a powerful analytical technique which allows detection of all

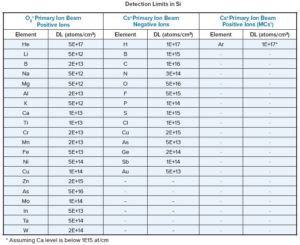

SIMS detection limits of selected elements in Silicon, providing a a list of detection limits for typical dopants and impurities

SIMS detection of all elements from H to U with excellent sensitivity. The table provides detection limits for impurities in a SiC matrix.

SIMS ZnO detection limits of selected elements under normal depth profiling conditions, showing overlay of SIMS profiles of arsenic implant

![SIMS measurement of Bulk [N], Table 1 Long term RSDs for three levels of [N]](https://www.eag.com/wp-content/uploads/2016/10/application-note-SIMS-measurement-of-bulk-N-in-nitrogen-doped-Cz-Si-long-term-precision-results-M-013716_Table_1a-300x150.jpg)

We have improved the SIMS measurement precision using the ASTM F 2139 test method and extended the detection capability into the 1×1013/cm3 levels.

Silicon Carbide SIMS Measurements provide valuable data for process control and problem solving in wafer growth and device manufacturing.

20th September 2022

Dive into how scientists at Eurofins EAG Laboratories tackled the problem of quantification of both major and minor elements in non-uniform, multi-element samples with abrupt or continuously graded composition changes using PCOR-SIMS.

In this webinar we will focus on Dynamic Secondary Ion Mass Spectrometry which used to investigate the elemental structure of materials.

A paper on the early days of SIMS quantification and its evolution throughout the years.

EAG Laboratories can offer a range of standards for SIMS used to calibrate materials such as Si, SiO2, SiN, Wsi, TiN, TiW, Al, GaAs, InP.

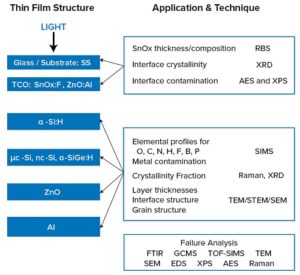

Surface analysis lab techniques on α-Si thin film PV, microcrystalline Si, nanocrystalline Si, amorphous SiGe, & microcrystalline SiC

Explore the hidden risks of impurities during manufacturing and how advanced methods like GDMS and ICP-MS help safeguard critical components.

PCOR-SIMS was originally developed to analyze Silicon Germanium (SiGe) devices for the communications industry.

VCSELs have several advantages, such as a higher modulation speed, which make them great for technological innovations.

Low-E Coatings on glass are a high efficiency protection of a glass surface for transparency. These coatings help the glass become energy efficient to allow the sunlight to come in or reflect out.

In this webinar we introduce Trace Analysis of Advanced Materials by Direct Solid-Sampling and Solution-Based Techniques

EAG Laboratories to provide comprehensive process development and failure analysis of vertical cavity surface emitting lasers.

HEMTs characterization using SIMS helps to uncover troublesome impurities, optimize epitaxial layer growth and aid failure analysis

High Depth Resolution Analysis will play a very important role in the electronic device industry as devices become smaller and smaller.

Vertical-cavity surface-emitting lasers, or VCSELs, play a major role in the consumer electronics 3D sensing industry.

Comparing and summarizing the features of magnetic field type SIMS instruments and quadrupole type SIMS instruments

What is the difference between SIMS and TOF-SIMS? SIMS (Secondary Ion Mass Spectrometry) and TOF-SIMS (Time of Flight-SIMS) are the same in terms of mass

Compound semiconductor films are grown with different matrix compositions that affect the elemental sensitivities and sputtering rates

Discover the power of LiDAR technology behind the scenes. Learn about the role of SIMS in the world of LiDAR to reveal the chemical makeup of materials.

To enable certain features and improve your experience with us, this site stores cookies on your computer. Please click Continue to provide your authorization and permanently remove this message.

To find out more, please see our privacy policy.