A Solution for Sensitive Materials – Cryo FIB

Cryo FIB uses a cold sample stage that can be controlled to -135°C making it it more suitable for temperature sensitive materials.

Home » Polymers

Cryo FIB uses a cold sample stage that can be controlled to -135°C making it it more suitable for temperature sensitive materials.

Polymer surface modification by Atomic Force Microscopy (AFM) for understanding surfaces of medical device polymers for biocompatibility.

In this webinar we introduce Analytical Investigations of Plastics and Polymers to tackle failure issues quickly and effectively

EAG offers expertise in polymer chemistry, with analytical services from basic characterization of materials

During this live Ask the Expert event, we will answer pre-submitted questions from our audience regarding characterization of polymeric materials used for product development, R&D, and failure analysis.

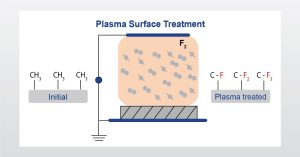

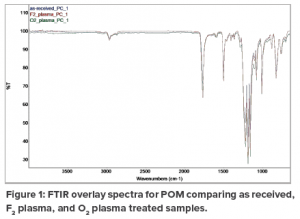

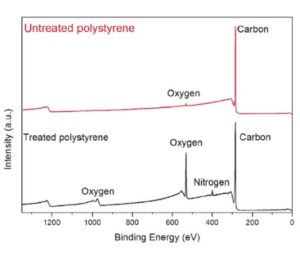

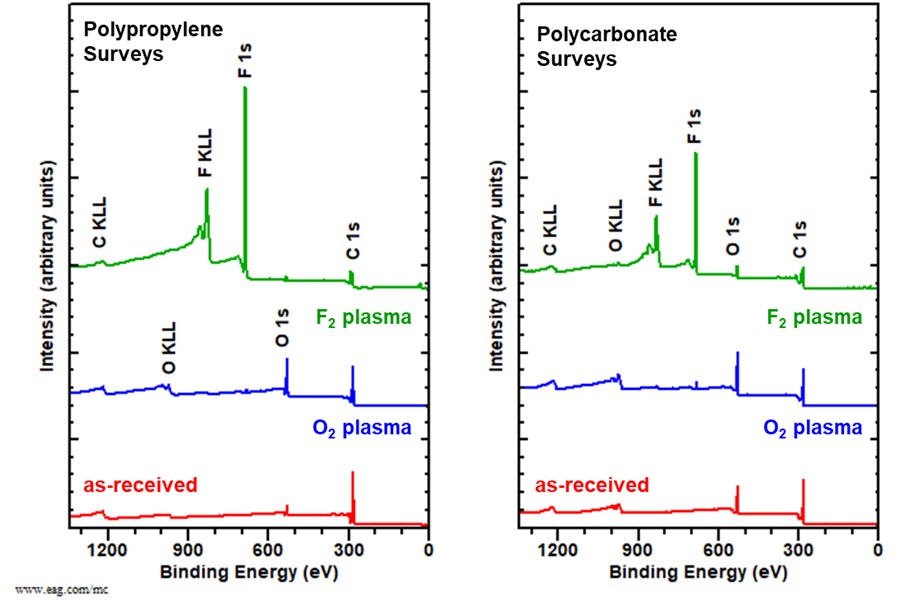

In the full webinar we will discuss how the surface properties of polymers are altered by plasma treatment using characterization techniques

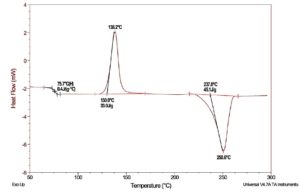

DSC analysis of polymers provides polymer characterization & thermal properties for product improvement and problem solving.

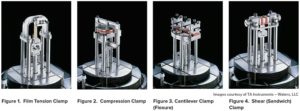

Polymeric materials characterization: Dynamic mechanical analysis (DMA) to study viscoelastic properties under conditions of low applied mechanical force.

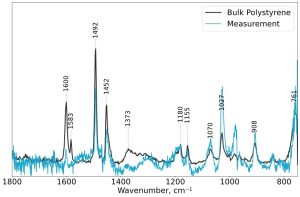

NanoIR is highly suited for identification of organic components that cannot be conventionally analyzed by other organic analysis techniques such as FTIR or Raman.

In this webinar we introduce Chemical Compatibility of Polymers in Medical Devices and prevent material problems in the field

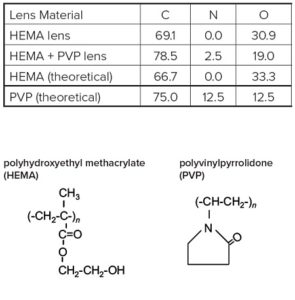

EAG Laboratories helps you understand contact lenses surface chemistry, critical to optimizing design and engineering optimal performance.

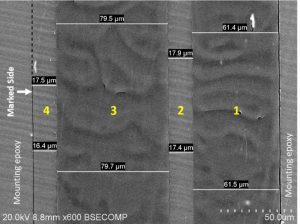

An injection molded component in a consumer product was found to have an increased failure rate over a three-month period.

A client requested assistance to investigate a recurrent issue with the curing failure of a silicone adhesive joint between metal components.

A client wanted to investigate the delamination of food packaging multilayer laminate. Roll stock did not meet seal strength specification.

A company was investigating environmental stress cracking of polycarbonate components used in a conveyor device that was sanitized.

For more than 50 years, EAG Scientists and Engineers have investigated and resolved product failures for clients

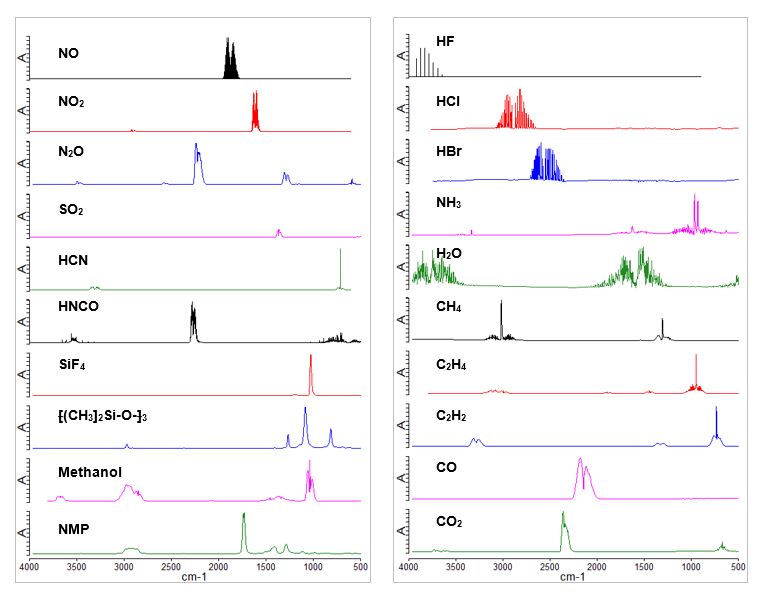

Fourier Transform Infrared Spectroscopy (FTIR) is a analytical technique for characterizing organic and some inorganic materials

FTIR and Raman are spectroscopy techniques that provide molecular information from various types of materials.

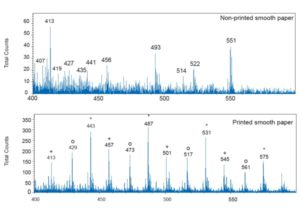

TOF-SIMS is a technique that can observe elemental, inorganic and molecular species present on the outermost surface of a sample

Imaging Cross-Sections by TOF-SIMS provides molecular information with high spatial resolution for the distribution of organic molecules

A device manufacturer observed defects in a lot of thermoplastic tubing. The tubing exhibited signs chemical attack or exposure to heating.

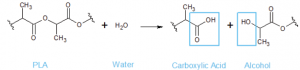

This App Note shows the approach of EAG Laboratories to test the material reliability of PLA Polymer Degradation

Cracks were observed in transparent thermoformed plastic packaging during visual quality checks. Failures occured in specific material lots.

Understanding the construction/composition of films is beneficial for a variety of reasons

Analytical testing to support changes in raw materials and processing conditions used in manufacturing memory foam, as well as odor

EAG provides packaging analysis and innovation by combining analytical chemistry, polymer expertise and specialized microscopy techniques

In this webinar we introduce Polymer Additive Manufacturing analysis that prevents defects in 3D-printed objects

Plastic testing services from EAG offers insight into thermoplastics, elastomers, thermosets, specialty polymers, polyurethanes, coatings.

Blisters were observed in paint applied to steel plates that had undergone treatment with a corrosion inhibitor. An investigation was performed to determine if there was evidence of contamination on the inside of the blister.

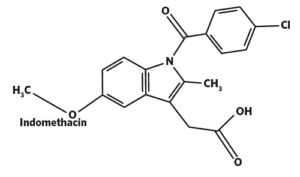

API Quantification on the Surface of Pharmaceuticals can be done by X-ray Photoelectron Spectroscopy (XPS) from EAG Laboratories.

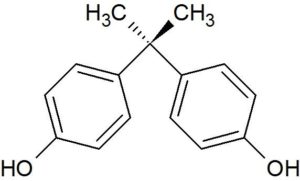

BPA analysis to quantify Bisphenol A levels in products using proprietary analytical methods using HPLC with a flourescence detector.

As the list of restricted substances grows, testing demands customized methods to identify issues early. This is a complex issue that requires a strategic approach.

Analytical tools to understand chemical properties of polymers for adhesion, printability, barrier performance, appearance and strength

Synthetic polymers are widely used in many industry sectors. TGA-FTIR is used for materials characterization and outgassing profiling.

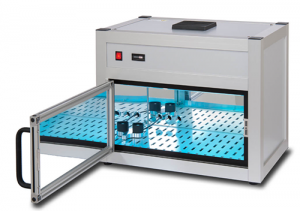

UV-C Irradiation For Product Reliability Testing Ultraviolet light (UV-C) is used for the disinfection of surfaces, air and water. It is able to destroy the

Polymeric films used in an outdoor application experienced reduced adhesion over time. The client suspected that UV degradation was occurring.

Polymer materials are in medical devices, automobiles, electronics, food packaging and in a wide range of industrial and consumer products.

To enable certain features and improve your experience with us, this site stores cookies on your computer. Please click Continue to provide your authorization and permanently remove this message.

To find out more, please see our privacy policy.