Ask the Expert: Residual Gas Analysis

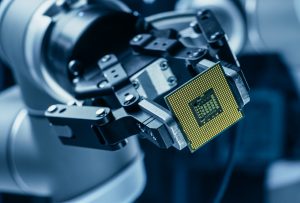

RGA is ideally suited for process development, sealing quality control, studying long-term outgassing of the enclosed materials inside the components, and for product qualification.

Home » Gas Analysis

RGA is ideally suited for process development, sealing quality control, studying long-term outgassing of the enclosed materials inside the components, and for product qualification.

Aerospace and defense government suppliers can have confidence in EAG’s credibility in providing accurate and high-quality testing services.

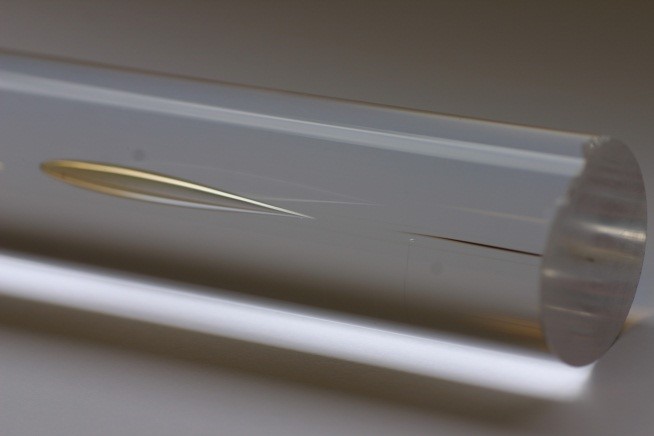

The chemical composition of all kinds of glass defects can be determined by SEM combined with EDS, XRF, Auger, and RGA.

13th December 2022

Manufacturing Technology Insights recently named EAG Laboratories a Top 10 Corrosion Services Provider. The publication featured an interview with Dana Medlin, our Vice President of Metallurgical Engineering.

August 28, 2023

Manufacturing Technology Insights named Eurofins EAG Laboratories a Top 10 Corrosion Services Provider for the second year in a row.

17th November 2022

EAG has been approved as a suitable commercial laboratory to provide MIL-STD 883/750 Test Method 1018 Internal Water Vapor Content Testing for hermetically sealed electronic devices.

8th June 2023

Now, with RGA included in the scope of ISO 17025, RGA testing at EAG is a premium choice to perform gas analysis.

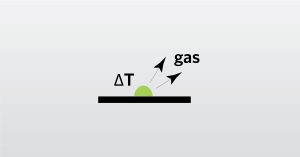

All materials have trapped gasses inside. Learn how EAG utilizes Evolved Gas Analysis to analyze what gasses are being released.

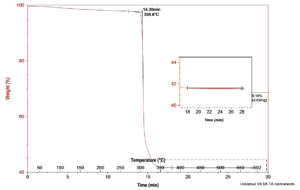

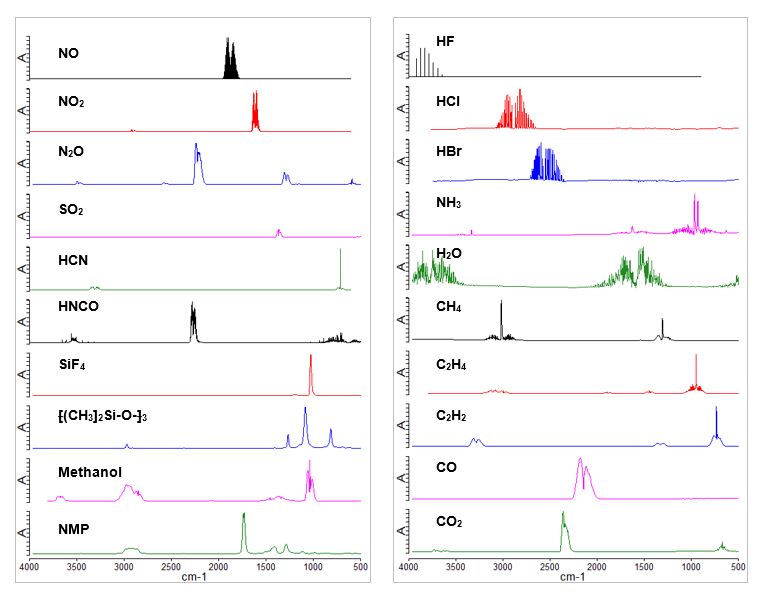

TGA with hyphenated technologies such as infrared (IR) and/or mass spectrometry (MS) is investigates the outgassing behavior of materials

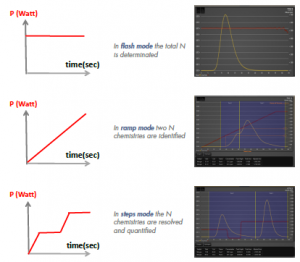

In this webinar we introduce Residual Gas Analysis (RGA), Evolved Gas Analysis (EGA), and Cumulative Helium Leak Detection (CHLD)

Ensure reliability, safety, and performance with Gas Analysis Testing

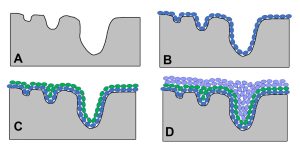

Additive manufacturing calls for powder feedstock of metals, alloys and ceramics, with particle size typically in 100s nm – 10s μm range.

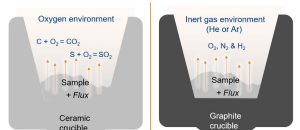

This webinar will focus on Instrumental Gas Analysis (IGA) that measures gas-forming elements present in solid materials.

IGA Services from EAG Laboratories measures gas-forming elements (C, H, O, N and S) in samples from ppm to percentage levels.

The term ‘rare earth elements’ (REEs) is a misnomer and better refers to the relatively rare ores REEs are extracted from; rare earth elements are all around us!

To be hermetically sealed essentially means to be airtight so that nothing can come in or get out (i.e., gas, moisture, liquid, etc.).

Superalloys, combine two ore more elements of which one is Ni, Co, or Fe, and provide strength, toughness, and durability at high temps.

Surface area and pore structure are important considerations in many fields, impacting diverse industry concerns.

RGA provides valuable data for optimizing battery safety, performance, and longevity.

Thermal Analysis Techniques at EAG include TGA, DSC, TMA and DMA help with materials identifications, failure analysis and deformulation.

Synthetic polymers are widely used in many industry sectors. TGA-FTIR is used for materials characterization and outgassing profiling.

In this webinar we introduce Trace Analysis of Advanced Materials by Direct Solid-Sampling and Solution-Based Techniques

To enable certain features and improve your experience with us, this site stores cookies on your computer. Please click Continue to provide your authorization and permanently remove this message.

To find out more, please see our privacy policy.