2D/3D realtime X-ray inspection solutions

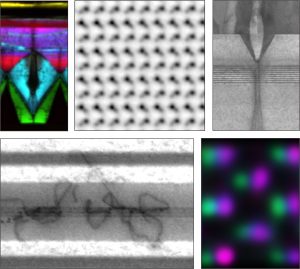

As components get more complex, nondestructive inspection techniques like X-Ray and CT scanning help uncover issues and anomalies

Home » Failure Analysis

As components get more complex, nondestructive inspection techniques like X-Ray and CT scanning help uncover issues and anomalies

Electronic systems failure analysis methodology and workflow by applying FIB circuit edit techniques for solving electronic problems.

In this webinar, we will explore the variety of microscopy techniques available at Eurofins EAG commonly utilized to characterize compound semiconductor materials.

At Eurofins EAG Laboratories, we have utilized Plasma Focused Ion Beam (PFIB) to overcome the limitations of traditional deprocessing methods.

During this live Ask the Expert event, we will answer pre-submitted questions from our audience regarding characterization of polymeric materials used for product development, R&D, and failure analysis.

During this live Ask the Expert event, we will answer pre-submitted questions from our audience regarding materials analysis with various surface contact and optical analytical techniques.

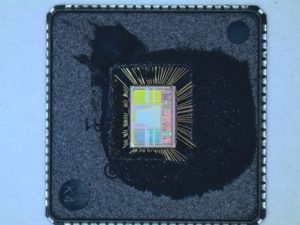

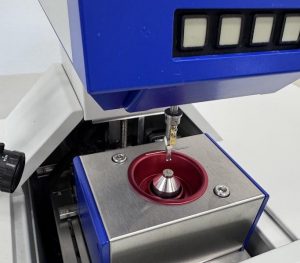

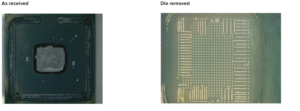

Chemical Decapsulation: Creation of a cavity on the package surface of an electronic component to expose the die underneath for inspection.

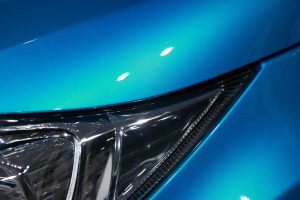

EAG’s coatings testing lab provides deformulation, VOC EPA 24 testing, and other ASTM paint evaluations for product improvement and troubleshooting.

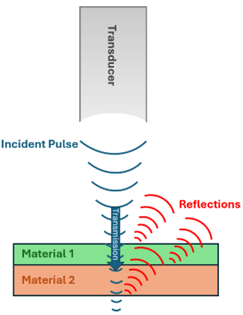

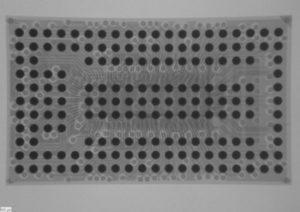

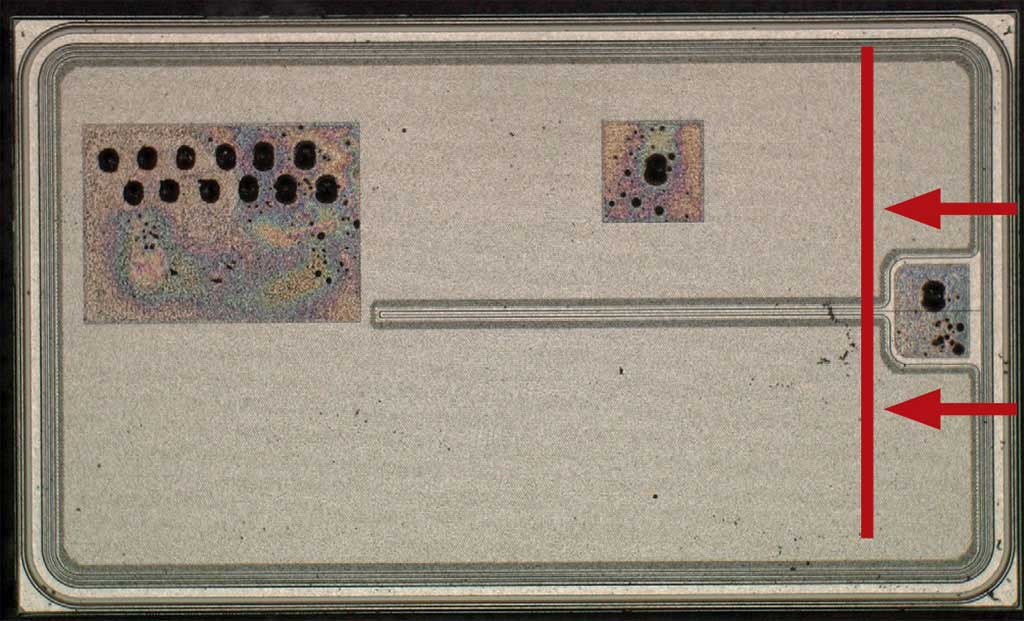

Complementary Techniques: X-Ray & SAM X-ray imaging is a great non-destructive technique that is used in many industries to help visualize internal construction. Scanning acoustic

This webinar covers FDA regulation of medical devices, the most commonly used test standards, and custom testing at Eurofins EAG Laboratories.

An injection molded component in a consumer product was found to have an increased failure rate over a three-month period.

A client requested assistance to investigate a recurrent issue with the curing failure of a silicone adhesive joint between metal components.

A client wanted to investigate the delamination of food packaging multilayer laminate. Roll stock did not meet seal strength specification.

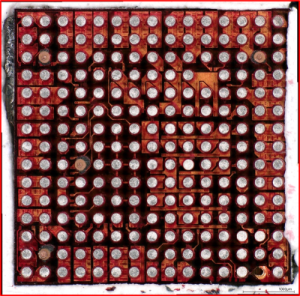

Dye and Pry is an excellent way to inspect a large number of bonds (leads, solder ball, seals..) at one time

In this webinar we introduce Dye and Pry that involves cleaning a sample to remove debris & flux around solder, then exposing it to a red dye.

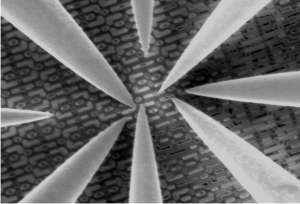

Nanoprobing is a highly specialized analytical technique used in semiconductor physics and electronics industries.

25th August 2023

We are thrilled to announce our latest nanoprobing capabilities at EAG, powered by cutting-edge Kleindiek equipment. Nanoprobing is an advanced analytical technique that enables the direct measurement and characterization of front and backend structures.

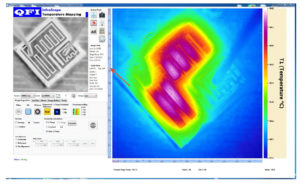

QFI Instrument Services and electrical localization services from EAG Laboratories are upgraded with LSM and XIVA image.

In this webinar we introduce failure analysis of ICs and other components in the product development cycle and for improving current products

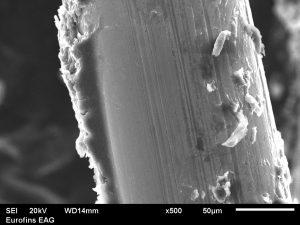

A company was investigating environmental stress cracking of polycarbonate components used in a conveyor device that was sanitized.

In the aerospace industry, electronics are subjected to extreme environmental variables. EAG’s failure analysis group can help solve potential problems that may arise.

Expert failure analysis will shorten development cycles.

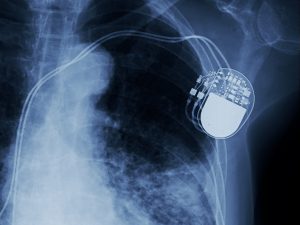

As medical devices become more complex, there are many more opportunities for things to go awry. Identifying, diagnosing, and remedying failures becomes dramatically more challenging. We can help.

Failure analysis metals, nonmetals and composites for aircraft, aerospace, transportation, construction, consumer products, and electronics.

Failure Analysis and product improvement of metal components is a specialty at EAG Laboratories

EAG Laboratories has the engineering expertise and advanced equipment and tools for microelectronic failure analysis of products and systems.

For more than 50 years, EAG Scientists and Engineers have investigated and resolved product failures for clients

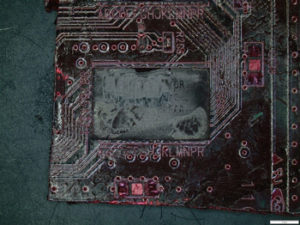

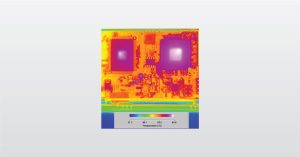

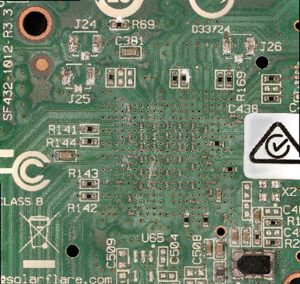

With in-depth images and analyses, EAG is able to examine the root cause of failures, critical dimensions, and quality of assembly process. Our experts can assist in PCB improvement.

In this webinar we introduce The Failure Analysis of Reliability Testing Samples as applied electronic and semiconductor devices

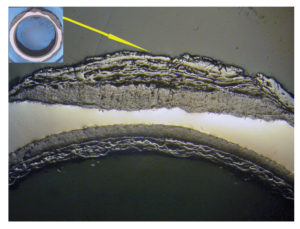

Failure inspection during post reliability stress testing to ensure no delamination, voids, cracks, material density changes.

Food packaging materials can be made with plastics, paper and board, glass, metal, wax, and printing inks. These packaging materials are directly and indirectly in contact with our food.

In Vitro Diagnostics test and system development support from the materials sciences experts at EAG Laboratories, contact us today!

A device manufacturer observed defects in a lot of thermoplastic tubing. The tubing exhibited signs chemical attack or exposure to heating.

March 30 – April 3, 2025

Eurofins EAG Laboratories will be presenting a poster, Failure Analysis of Particle Contamination in Battery, at IRPS in Monterey, CA.

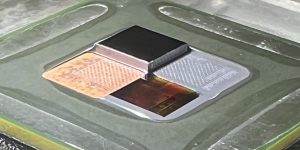

Laser decap at EAG Laboratories includes our Failure Analysis Laser Inspection Tool, view our picture book of PC boards before and after.

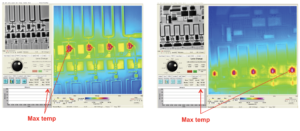

LED characterization, from process control to failure analysis to construction analysis, EAG Laboratories supports your LED analysis needs.

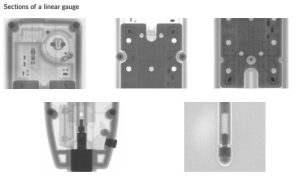

Level 1 Failure Analysis includes: non-destructive tests optical inspection, X-ray, C-SAM, and electrical characterization.

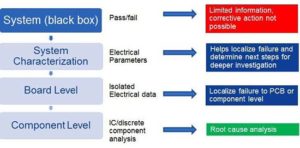

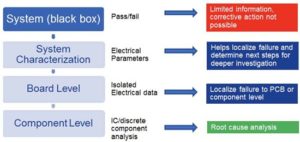

EAG divides FA tasks into three levels. In each level, we employ optimal techniques for device characterization, defect localization, and root cause failure analysis.

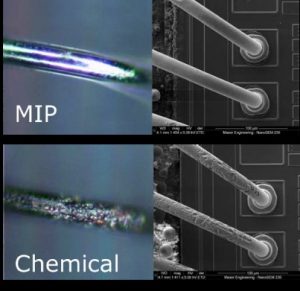

Microwave-Induced-Plasma (MIP) decapsulation allows for damage free removal of the protective cover of semiconductor packages.

Cracks were observed in transparent thermoformed plastic packaging during visual quality checks. Failures occured in specific material lots.

Understanding the construction/composition of films is beneficial for a variety of reasons

Analytical testing to support changes in raw materials and processing conditions used in manufacturing memory foam, as well as odor

Package Delayering services helps to look for opens, shorts, leakage and damage in the layers and design rule distances in the sample.

Solving CSP qualification testing challenges by addressing key issues and applying specialized processes through EAG know-how.

Blisters were observed in paint applied to steel plates that had undergone treatment with a corrosion inhibitor. An investigation was performed to determine if there was evidence of contamination on the inside of the blister.

EAG is excited to announce our latest sample preparation capability to address the emerging challenges of complex and advancing technologies.

The common method of dye & pry can result in the cracking and shattering of die. EAG has altered the common dye & pry method, which has resulted in a significantly improved success rate.

Electronic system failure analysis requires expertise in the modes of failures and techniques such as SEM, TEM, and dual-beam FIB.

As electronic assemblies become more complex, ensuring high quality solder joints is critical for long term performance and reliability.

November 18, 2025

Join us for an afternoon of snacks as you learn about the latest applications from our battery materials experts. Enjoy networking with peers and getting to know our scientists.

RGA provides valuable data for optimizing battery safety, performance, and longevity.

October 6-9, 2025

We are excited to announce that Eurofins EAG Laboratories will be speaking at The Battery Show in Detroit, MI, October 6-9.

Failure analysis plays a crucial role in the development and maintenance of medical device electronics.

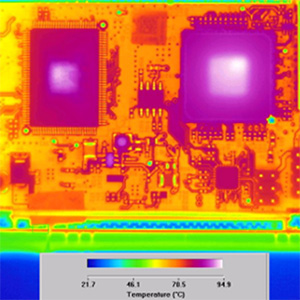

Temperature measurements of RF transistors to examine temperature distribution and look for areas of heating issues on many types of devices.

Time Domain Reflectometry (TDR) services from EAG – Each layer in the package may be inspected optically and probed electrically.

Polymeric films used in an outdoor application experienced reduced adhesion over time. The client suspected that UV degradation was occurring.

June 3-4, 2025

Join us for our Failure Analysis seminar! Enjoy networking with peers and expert technologists, share challenges in our interactive user group session, and take advantage of optional tours of nearby lab facilities.

In our interconnected and changing world, it is important to know how to respond to potential electronic system failures.

Learn about how metallurgy plays a critical role in infrastructure safety, revealing how corrosion, fatigue, and poor material choices can lead to catastrophic collapses.

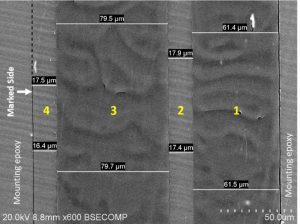

Cross sectioning of a semiconductor die is a basic step in failure analysis work. A cross section can be used as a check of layer integrity.

X-ray images from EAG include PCB layers, PC Board views, QFN, PCB Vias, QFP, Flip Chip, 9V Battery, BGA and BGA tilt and rotate.

To enable certain features and improve your experience with us, this site stores cookies on your computer. Please click Continue to provide your authorization and permanently remove this message.

To find out more, please see our privacy policy.