A Deep Dive into High Powered Electronics

High Powered Electronics are used in a wide suite of applications, from consumer electronics and electric vehicles to railways and power plants and even artificial intelligence.

Home » Energy

High Powered Electronics are used in a wide suite of applications, from consumer electronics and electric vehicles to railways and power plants and even artificial intelligence.

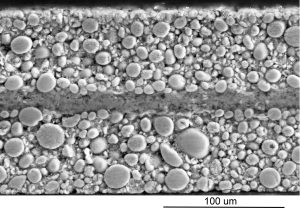

TEM, STEM and AC-STEM techniques deliver high resolution images providing a detailed view of a material or product.

Cryo FIB uses a cold sample stage that can be controlled to -135°C making it it more suitable for temperature sensitive materials.

5th – 8th December 2022

Eurofins EAG Laboratories will be attending the Advanced Automotive Battery Conference. Please visit us at booth #812.

23rd October 2022

Industry Service Labs play a critical role in the battery community by providing fast and professional service. Learn how Eurofins EAG Laboratories can help!

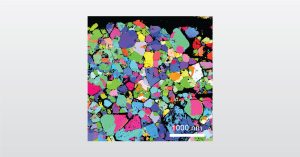

Solids fall under two main categories: amorphous and crystalline. These two types of solids have different properties that may be more beneficial for certain products or applications.

CIGS Thin Film PV performance reliability and uniformity as manufacturing is scaled up, can be optimized using materials characterization.

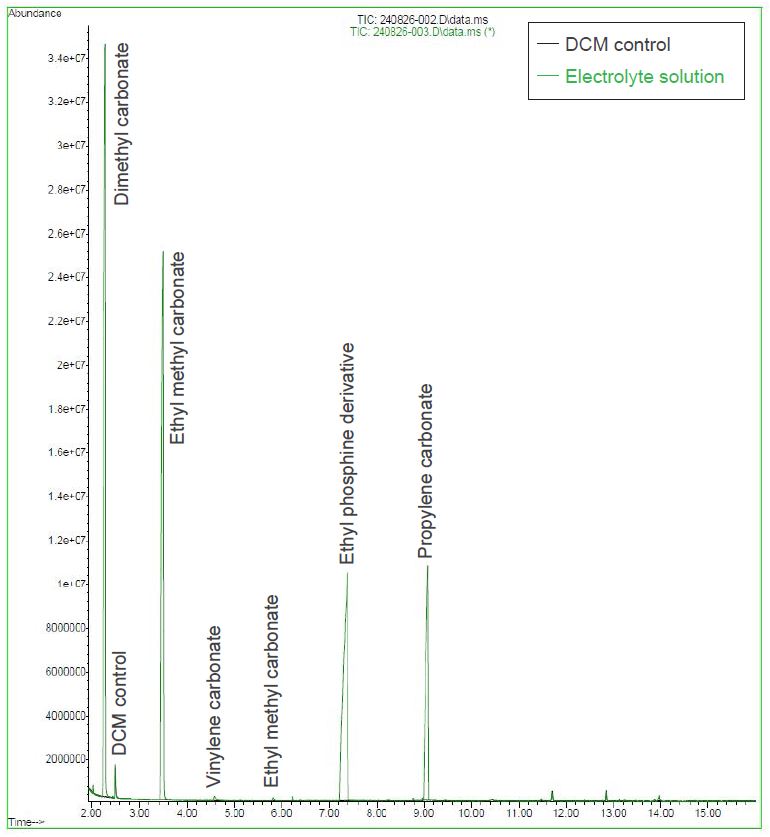

The GC-MS method offers a simple, reliable, and accurate approach for analyzing the composition of lithium-ion battery electrolytes and ensuring quality control.

In this webinar we introduce the application of Electron Microscopy to Lithium Ion Batteries from Micron to Atomic Level

Eurofins EAG offers analytical techniques and expertise to allow a full understanding of the materials used in the cathodes, anodes and electrolytes.

October 23

During this live Ask the Expert event, we will answer pre-submitted questions from our audience regarding brazing.

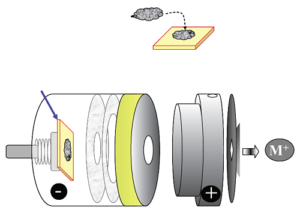

With the demand of lithium-ion batteries, it is critical to understand the structure and composition with high spatial resolution.

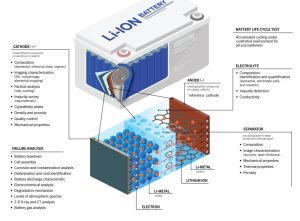

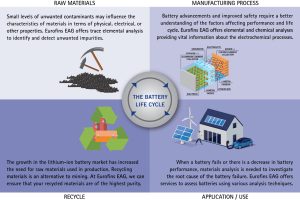

Eurofins EAG Laboratories is your partner for battery materials testing throughout the battery life cycle. From raw materials to product failures, we can provide the data needed to help you provide top quality and high-performance products to market faster.

Assessing the chemical state of various components of a battery, from the cathode to the current collectors, at different stages of cycling, provides crucial insights into the electrochemical processes that occur during battery operation.

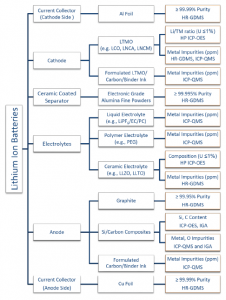

At EAG, we deliver specialized analytical services that support testing throughout the battery life cycle including purity testing of raw and recycled materials, materials R&D, battery manufacturing, and failure analysis.

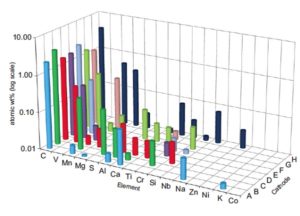

Battery Raw Materials Analysis Battery manufacturing is a meticulous process where the integrity and performance of the final product hinge on the purity of its

Battery recycling of key materials such as cobalt, nickel, and lithium require precise and accurate determination of elemental compositions

Battery materials characterization services includes analysis of raw materials, surface chemistry, composition, morphology and uniformity

EAG offers a wide-range of material characterization services specifically for the battery industry to help with R&D and manufacturing

CdTe Thin Film PV manufacturers benefit from surface analysis techniques such as SIMS, GDMS, SEM,TEM to support efficiency improvements.

In this webinar we introduce full Survey Chemical Analysis of Materials Used in Energy Storage Devices such as lithium ion batteries

Chemical analysis techniques that can help to evaluate the composition of materials that are used for manufacturing Lithium Ion Batteries

Photovoltaic Element Determinations by GDMS is ideally suited for trace element monitoring of PV grade CdTe/CdS materials.

XRF is a non-destructive technique that is used to quantify the elemental composition of materials.

Eurofins | EAG Laboratories is proud to announce the expansion of its battery materials testing capabilities, with a new purpose-built 6,600 square-foot laboratory located in Sunnyvale, CA. and expanded facilities in Syracuse, New York.

All materials have trapped gasses inside. Learn how EAG utilizes Evolved Gas Analysis to analyze what gasses are being released.

APT is a nanoscale materials analysis technique that provides 3D spatial imaging and chemical composition measurements with high sensitivity simultaneously.

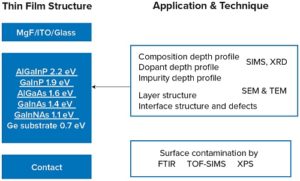

III-V solar cell technology for concentrator PV systems is the focus of this app note, illustrating the way that surface analysis can help

Battery characterization improves lithium-ion battery safety and performance using techniques such as SEM, TEM, XPS, GDMS, FTIR, ICP-OES, Raman and failure analysis

EAG scientists are leaders in the lithium-ion batteries recycling arena. EAG is a valuable resource in understanding these materials.

In this webinar we introduce analytical techniques for the characterization of Li-ion battery electrode (cathode) at different length scale

PFIB differs from traditional FIB in that it uses various gases such as Xe, Ar, oxygen or nitrogen to generate a plasma that is used to remove material from a sample.

The term ‘rare earth elements’ (REEs) is a misnomer and better refers to the relatively rare ores REEs are extracted from; rare earth elements are all around us!

Impurities adversely affect performance of a CIGS solar cell, with varying concentrations – SIMS can help measure representative sampling.

Silicon wafer solar cells and the analytical techniques used to investigate failures, bulk defects and other materials characterization.

EAG provides solar industry with expert analysis of material properties, composition and chemistry to improve supply chain and manufacturing.

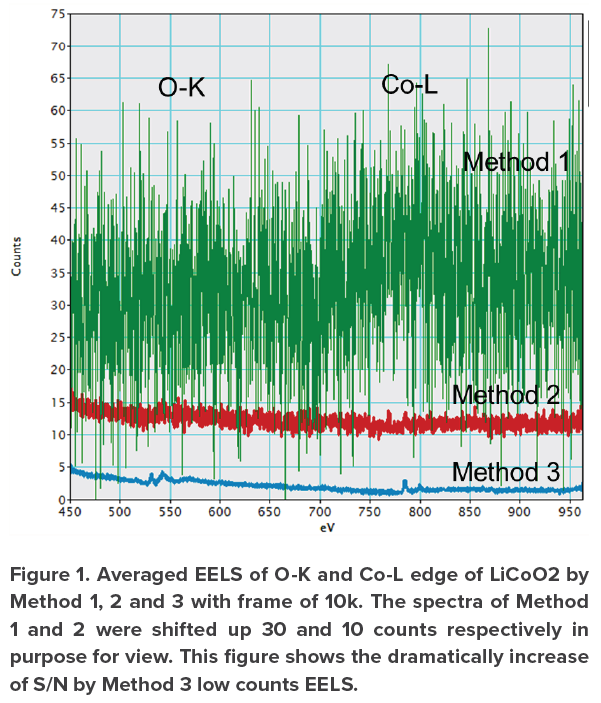

Structural and Chemical Characterization of Li-ion Batteries help to understand why batteries fail leading to safer products and improvements.

Supplier verification can be critical to the long-term success of your product and business. At Eurofins EAG, our technical experts have many years of experience working with battery materials. We are your battery partner to bring your product to market faster and more efficiently.

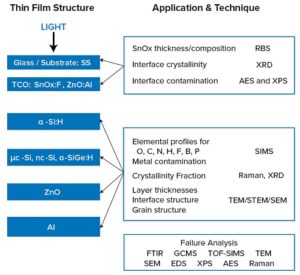

Surface analysis lab techniques on α-Si thin film PV, microcrystalline Si, nanocrystalline Si, amorphous SiGe, & microcrystalline SiC

As the battery industry continues to evolve, Eurofins EAG Laboratories is your partner to bring your product to market faster and more efficiently.

There is still so much to learn about batteries, including challenges such as energy density, cycle life, fast charge, and safety. In this blog, we’ll be focusing on energy density.

LA-ICP-MS is a technique that uses direct micro-scale sampling to provide high precision elemental characterization of solid materials.

Lithium-ion batteries provide high energy density mobile power but come with three challenges: performance, safety and battery life.

Cryo TEM involves performing TEM analysis while keeping the sample at cryogenic temperatures, around -170°C.

To enable certain features and improve your experience with us, this site stores cookies on your computer. Please click Continue to provide your authorization and permanently remove this message.

To find out more, please see our privacy policy.