A Picture is Worth a Thousand Words – TEM, STEM and AC-STEM

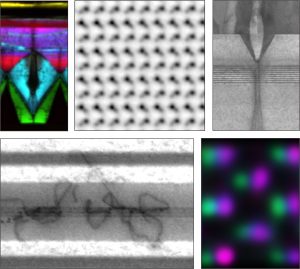

TEM, STEM and AC-STEM techniques deliver high resolution images providing a detailed view of a material or product.

Home » Consumer Products

TEM, STEM and AC-STEM techniques deliver high resolution images providing a detailed view of a material or product.

RBS is the one technique where we can really say that the composition and concentration are accurately determined for thin films.

In this webinar, we will explore the variety of microscopy techniques available at Eurofins EAG commonly utilized to characterize compound semiconductor materials.

Advanced Surface Analysis using TOF-SIMS on a flat panel display, discovering residue formed during the manufacturing process.

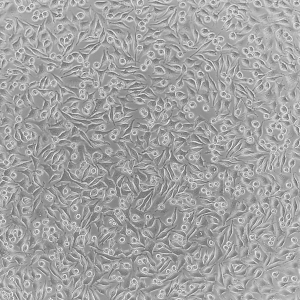

In vitro biocompatibility testing is a powerful tool in the risk assessment of wearable devices. View our webinar to learn more!

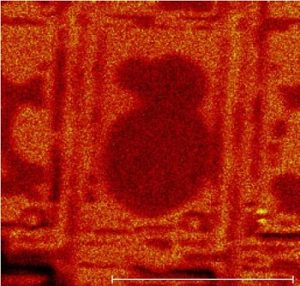

There are many key components of the VCSEL, but one challenging region is the oxide aperture. The oxide aperture is responsible for current confinement, and it is important to have high quality oxidation to prevent failure of the device.

EAG helps consumer products manufacturers build better by accelerating product innovation, improving raw materials & meeting all regulations.

An injection molded component in a consumer product was found to have an increased failure rate over a three-month period.

A client requested assistance to investigate a recurrent issue with the curing failure of a silicone adhesive joint between metal components.

A client wanted to investigate the delamination of food packaging multilayer laminate. Roll stock did not meet seal strength specification.

XRF is a non-destructive technique that is used to quantify the elemental composition of materials.

A company was investigating environmental stress cracking of polycarbonate components used in a conveyor device that was sanitized.

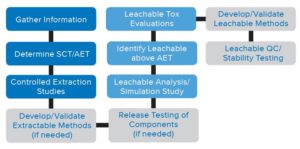

In this webinar we introduce Extractable and Leachable tests which identify chemical components that can migrate out of a product.

Failure analysis metals, nonmetals and composites for aircraft, aerospace, transportation, construction, consumer products, and electronics.

EAG Laboratories has the engineering expertise and advanced equipment and tools for microelectronic failure analysis of products and systems.

Food packaging materials can be made with plastics, paper and board, glass, metal, wax, and printing inks. These packaging materials are directly and indirectly in contact with our food.

FTIR and Raman are spectroscopy techniques that provide molecular information from various types of materials.

III-V materials partially provide us with the ever evolving and changing technological advances we enjoy today.

APT is a nanoscale materials analysis technique that provides 3D spatial imaging and chemical composition measurements with high sensitivity simultaneously.

Manufacturer-provided extractable data must be questioned and evaluated for your specific application. We outline the steps and questions.

E&L methods pose challenges as they transition from R&D environment to routine QC testing. Understanding these challenges will help you avoid costly delays.

In Vitro Diagnostics test and system development support from the materials sciences experts at EAG Laboratories, contact us today!

A device manufacturer observed defects in a lot of thermoplastic tubing. The tubing exhibited signs chemical attack or exposure to heating.

Cracks were observed in transparent thermoformed plastic packaging during visual quality checks. Failures occured in specific material lots.

Analytical testing to support changes in raw materials and processing conditions used in manufacturing memory foam, as well as odor

One of our surface analysis techniques, TOF-SIMS, can be used to characterize the surface coatings on screens and to compare the thickness of the coatings using depth profiles.

PFIB differs from traditional FIB in that it uses various gases such as Xe, Ar, oxygen or nitrogen to generate a plasma that is used to remove material from a sample.

Blisters were observed in paint applied to steel plates that had undergone treatment with a corrosion inhibitor. An investigation was performed to determine if there was evidence of contamination on the inside of the blister.

In Vitro testing uses cell-based biological models instead of animals or humans.

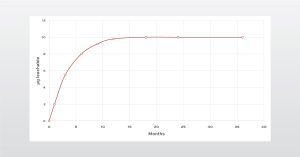

EAG has established product reliability test processes. In this example we inspect a Bluetooth speaker using Accelerated Testing.

As the list of restricted substances grows, testing demands customized methods to identify issues early. This is a complex issue that requires a strategic approach.

For over 30 years EAG has supported customers creating consumer electronic products

In this webinar we introduce Leachables stability studies and will cover impurities, method and stability requirements.

VOC testing of paints and coatings per EPA Method 24. EAG ensures your company meets standards for volatile organic compound testing.

Polymeric films used in an outdoor application experienced reduced adhesion over time. The client suspected that UV degradation was occurring.

In our interconnected and changing world, it is important to know how to respond to potential electronic system failures.

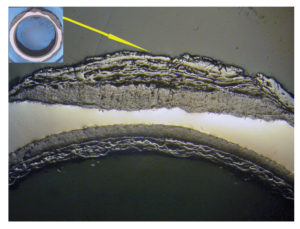

Cryo TEM involves performing TEM analysis while keeping the sample at cryogenic temperatures, around -170°C.

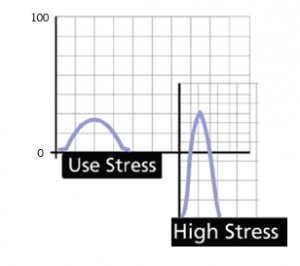

In this webinar we introduce evaluating wearable safety including product recall, lawsuits, and regulatory agency inquiries.

Consumer wearables are evaluated for sensitizers by extractable & leachable studies. We describe how to evaluate potential safety issues.

To enable certain features and improve your experience with us, this site stores cookies on your computer. Please click Continue to provide your authorization and permanently remove this message.

To find out more, please see our privacy policy.