Additive Manufacturing (3D Printing): Metallurgical and Material Services

Additive manufacturing is transforming how products and parts are manufactured that in more cost-effective solution.

Home » Additive Manufacturing (3D Printing)

Additive manufacturing is transforming how products and parts are manufactured that in more cost-effective solution.

Additive Manufacturing (3D printing) enables the creation of products with freedom in design and choice of polymers, metals, and ceramics.

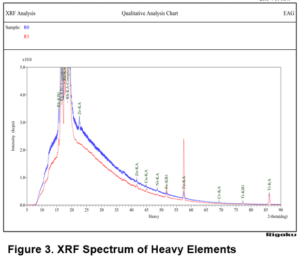

Recycled ABS Materials show numerous deleterious effects on molecular integrity of plastic materials, as seen in FTIR, XRF and GPC

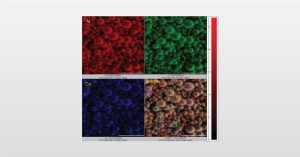

XRD analysis provides identification of crystalline phases present. For 3D printed materials that come from a matrix of multiple elements, it can be unclear whether the cooling creates one, consistent phase of material or if it separates out into multiple phases.

GC-MS can help with failure analysis or contamination characterization analysis on 3D printed parts. Utilizing a variety of different sampling techniques, GC-MS is a versatile tool that can identify specific species of volatile organic compounds.

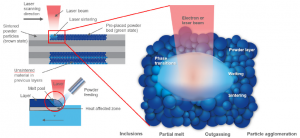

Additive manufacturing calls for powder feedstock of metals, alloys and ceramics, with particle size typically in 100s nm – 10s μm range.

In this webinar we introduce Metal Based Additive Manufacturing Analysis to understand and evaluate many aspects of the metallurgy.

Additive manufacturing produces parts with geometric complexity, material composition gradient control, and lightweight structure design.

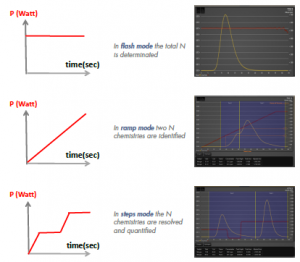

In this webinar we introduce Polymer Additive Manufacturing analysis that prevents defects in 3D-printed objects

In this webinar we introduce Multiscale Assessment on the Quality of Metal Powder Feedstocks for Additive Manufacturing

For 3D printed products, XPS can provide composition and bonding information for the top 5-10nm sample surfaces. Oftentimes, surface contamination/oxide thickness would affect the appearance (as well as performance when applicable) of the material, and XPS could help identify the source and/or cause.

In this webinar we introduce analytical techniques used by EAG for surface analysis – XPS, Auger and TOF-SIMS

Composition can play a critical role in the performance of a 3D printed product. It’s good to know that analytical testing can help verify elemental composition.

To enable certain features and improve your experience with us, this site stores cookies on your computer. Please click Continue to provide your authorization and permanently remove this message.

To find out more, please see our privacy policy.