Battery Materials Analysis

Home » Services » Materials Testing & Analysis » Battery Materials Analysis

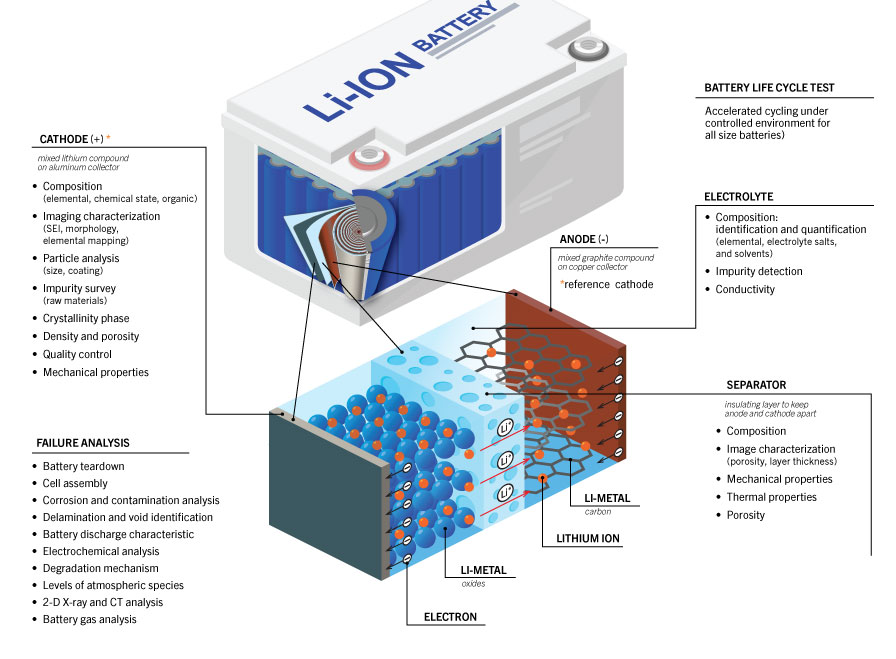

Today’s advanced batteries require a range of specialized analytical tools to better understand the electrochemical processes that occur during battery cycling. A full understanding of the materials used, and their behavior with respect to the cycle life of the battery system, can provide valuable information regarding the processes occurring within the battery. This can also provide useful insight into potential failure mechanisms.

Batteries contain a wide range of metallic, inorganic and organic components, with dimensions of interest ranging from Å to cm in size. Using suitable tools to investigate these components is essential.

Eurofins EAG offers analytical techniques and expertise to allow a full understanding of the materials used in the cathodes, anodes and electrolytes. We have the capabilities to address materials issues associated with all stages of battery development, including supply chain, materials R&D, and failure analysis.

Learn More About EAG's Battery Materials Analysis Services

Download the Battery Materials Analysis Brochure Today!

Battery Analysis of Raw Materials

The chemical purity of raw materials in battery production is of utmost importance to today’s materials engineers. Even the presence of such small levels of unwanted contaminants may influence the characteristics of materials in terms of physical, electrical, or other properties; thereby, adversely affecting the reliability of the final product. Systematic inspection of raw materials prior to production can aid in the detection and identification of sources of unwanted impurities. Eurofins EAG offers numerous techniques to determine the trace or ultra-trace level impurities in a wide variety of advanced materials.

Battery Analysis during the Manufacturing Process

With increasing demands for higher battery performance and improved safety, a better understanding of the factors affecting performance, life cycle and possible failure mechanisms is essential. Measuring the chemical state of the cathode, anode, separator, electrolyte, contact layers and additives, at various stages of cycling, provides vital information about the electrochemical processes that occur during battery use. Eurofins EAG offers elemental and molecular analyses using different analytical tools to address this need. We also offer microscopy techniques to investigate morphology, particle size, particle coatings, mixing efficiency and defects. These techniques also include elemental mapping capabilities which can provide further valuable information about elemental composition and location/distribution.

Battery Analysis after Application / Use

When a battery fails or there is a decrease in battery performance, materials analysis is needed to investigate the root cause of the problem. At Eurofins EAG, we offer services to assess battery performance using our various failure analysis techniques. We can disassemble batteries and isolate materials or components in question. Using a controlled environment specifically for moisture sensitive battery materials, we have the ability to transfer samples to instruments for analysis without exposure to air or moisture. Our wide range of materials characterization and microscopy techniques can provide detailed analytical data to help support the investigation.

Battery Analysis during the Recycling Process

As the lithium-ion battery market continues to grow, there has been an increased need for the raw materials used in battery production. Recycling materials from old batteries, such as lithium, nickel, cobalt, graphite and other elements, is an alternative to mining. Not only does it help sustain our environment, but it also has a positive impact on our economy. A concern that may arise in battery recycling is the quality of the recycled materials. At Eurofins EAG, our purity services can accurately determine lower level elemental impurities and can help ensure that your recycled materials are of the highest purity.

Download: Applications for Comprehensive Battery Analysis

Eurofins EAG Laboratories is your Battery Partner

With our many years of experience in working with battery materials, our technical experts have been exposed to a variety of problems throughout the battery life cycle.

From identifying impurities in raw and recycled materials to understanding and improving the manufacturing process and application, we work closely with our clients to help identify and solve problems.

As the battery industry continues to evolve, Eurofins EAG Laboratories is your partner to bring your product to market faster and more efficiently.

Related Resources

- Webinar: Investigations of Li-Ion Battery Electrode

- Webinar: Chemical Analysis of Energy Storage Devices

- Webinar: Electron Microscopy of Lithium Ion Batteries

- Blog: A Solution for Sensitive Materials – Cryo FIB

- Blog: Lithium ion Batteries

- Blog: Understanding Lithium-Ion Batteries

- Brochure: Battery Materials Analysis

- Brochure: The Battery Life Cycle - Materials Testing

- White Paper: Improving Performance and Safety of LIB

- App Note: Chemical Characterization of Li-ion Batteries

Would you like to learn more about our Battery Materials Analysis?

Contact us today for your Battery Materials Analysis needs. Please complete the form below to have an EAG expert contact you.