How do you know which materials testing approach to take? How do you choose the appropriate materials characterization techniques? How do you interpret analytical testing data to provide actionable results? EAG’s materials scientists and engineers know how to provide the essential information to improve product performance and develop new materials/processes.

When it comes to understanding the physical structure, chemical properties and composition of materials, no scientific services company offers the breadth of experience, diversity of analytical techniques or technical ingenuity of EAG. From polymers to composites, thin films to superalloys—we know how to leverage materials sciences to gain a competitive edge. At EAG Laboratories, we don’t just perform testing, we drive commercial success—through thoughtfully designed investigations, technically superior analyses and expert interpretation of data.

EAG Laboratories brings unparalleled materials sciences expertise in surface analysis, composition and contamination measurement, trace elemental analysis and advanced microscopy to support commercial initiatives across a broad spectrum of industries, from medical devices and pharmaceuticals, to aerospace and defense, to a range of high technology industries.

- Materials purity and biocompatibility

- Surface chemistry and cleanliness

- New process development

- Reverse engineering & deformulation

- Failure analysis

- Purity evaluation

- Corrosion and contaminant identification

- For raw materials, new products, components, composite materials and engineering coatings

- Composition measurement

- Materials specification assessment

- Verification and validation of processes

- Process monitoring

- Rapid independent verification of internal lab results

- Trace elemental analysis

- Certifications include

- ISO 17025 and ISO 9001:2015

- DSCC, and DLA

- MIL-STD-750, MIL-STD-883and MIL-STD-1580 testing, including destructive physical analysis and residual gas analysis

- ITAR compliance

- Raw materials selection and qualification

- Manufacturing process development

- Confirmation of physical and chemical characteristics of ingredients, components and end products

- Product liability, intellectual property and insurance claims

- Critical review and interpretation of technical data

- Expert opinions and deposition/trial testimony

Typical Materials Testing & Analysis Services

Imaging techniques are used to investigate sample microstructure, morphology, particle size, grain size, particle coatings and defects.

Battery Analysis using a wide range of materials characterization services for supply chain, materials R&D, and failure analysis

We provide analytical and materials testing services to support the convergence of technology, pharmaceuticals, medical devices and diagnostics.

EAG can help you better understand your product’s chemistry by applying multiple instrumental analytical approaches.

Select “first time right” sustainable materials in product design and development based on risk assessment, perform materials and product testing, and find the root cause of failure.

We can determine the components of an unknown substance, confirm the identity of a suspect material or identify difference between similar materials.

EAG can help with determination of a chemical family to complete structure elucidation. We can determine the source and measure the effectiveness of contaminant removal and cleaning.

We can provide critical insights throughout a product life cycle, from materials selection early in the design process to quality control and failure analysis.

With years of experience, our custom synthesis team offers organic synthesis of compounds from the milligram to kilogram scale.

Also known as reverse engineering, deformulation is the separation, identification and quantitation of ingredients in a formulation.

We can help identify chemicals released or migrated from a product under normal or stressed conditions.

EAG can help investigate fractures, corrosion, discoloration, wear, adhesion/bonding and stress-related issues.

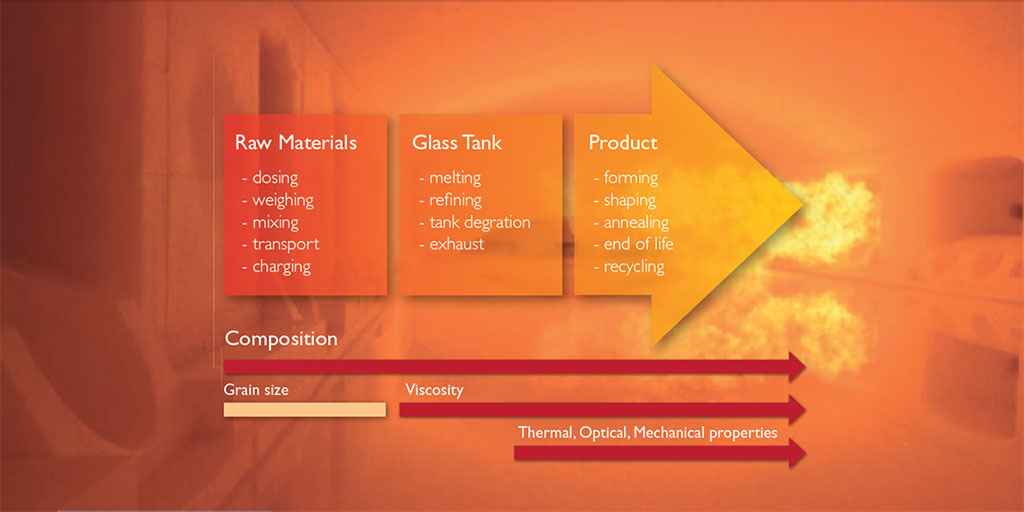

Glass is a crucial element in numerous applications. We have unmatched expertise in glass analysis, research and investigation.

Information about material properties include interface sharpness, depth distribution of a particular element, morphology, crystal structure and component identification.

EAG provides services for analytical investigations of fractures, fatigue, corrosion, oxidation, embrittlement, plating, welding, brazing and soldering problems in metallic and metal containing products.

We provide plastic and polymeric material testing for physical and mechanical properties, thermal properties and chemical composition analysis.

EAG has a range of specialized sample preparation and sample handling techniques that can significantly improve the likelihood of success in an analytical investigation.

EAG can help understand the composition, cleanliness, contaminant levels and roughness of surfaces to investigate issues with adhesion, corrosion and surface chemistry.

We can determine the chemical purity of materials to identify and eliminate contamination in advanced materials, typically categorized as mass fractions from 1 – 100 pm.

Since we began as Charles Evans & Associates in 1978, and continued as Evans Analytical Group for many years, we have been at the forefront for materials characterization and surface analysis services. Our quality certifications and accreditations provide a strong foundation for our laboratory locations around the world.

Would you like to learn more about Materials Testing & Analysis?

Contact us today for your Materials Testing & Analysis requests by completing the form below.