Failure Analysis of Microelectronic Products and Systems

Home » Failure Analysis of Microelectronic Products and Systems

As technologies and products become more complex, the resulting failure mechanisms and analysis also increase in complexity. EAG has the engineering expertise coupled with a significant investment in advanced microelectronic failure analysis tools and equipment to help you solve your most complex issues. We can provide comprehensive failure analysis of electronics products across a wide range of industries including automotive, energy, consumer and mobile, networking, and medical.

We perform a thorough analysis of the failure, identify the failure mechanism and why the failure occurred, and offer recommendations on how to prevent future failures. Our analytical service includes:

- Comprehensive third party reports

- Reverse engineering

- Quality assessment

- Competitor or construction analysis

- Full causal analysis

Using top down deductive analysis techniques, EAG has proven expertise in examining and identifying problems related to:

- Solder joints

- PCB and board level failures

- Differentiation of ESD/Electrical overstress (EOS)

- Manufacturing defects

- Field/customer returns

- Contamination and corrosion issues

Failure Analysis Levels of Service

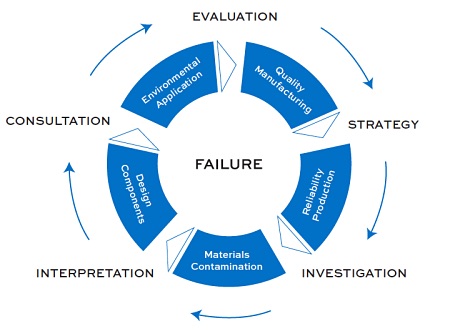

The ultimate goal in failure analysis is to arrive at an accurate determination of the cause of the failure. EAG has a proven, methodical process of failure analysis that is efficient but can be customized for your needs. For all levels of effort, EAG uses advanced tools and techniques coupled with expert interpretation to provide insight into the investigation and product failure.

TECHNIQUE

This is a focused approach designed to include one or more specific analysis techniques to understand, characterize or determine a defined task/need.

TURNKEY

Perform defined and established scope of analysis which may include failure verification, non-destructive package integrity examination and internal visual examination, fault isolation techniques to localize the failure to a specific site on a sample and/or physically identify and characterize the failure mechanism.

CONSULTATION

Lead a complex project to determine root cause of a failure, define corrective actions, design/product validation or improvements and other advanced engineering support.

Typical Industries

- Manufacturing

- R&D

- Military

- Aerospace

- Automotive

- Medical Device

- Semiconductor

- Industrial

- Consumer

Examples

- LED products

- Smart meters

- Consumer electronics

- Medical devices

- Automotive safety systems

- Military hardware

- Counterfeit components

- Home appliances

- Electronic toys

WHY EAG?

EAG Laboratories provides the specialized support and services you need to accelerate time to market, fill equipment and expertise gaps, and manage risk associated with product development.

Would you like to learn more about Failure Analysis of Microelectronic Products?

Contact us today for your failure analysis of microelectronic product needs. Please complete the form below to have an EAG expert contact you.