Eurofins EAG Enhances ATE Capabilities with New EXA Scale System

Eurofins EAG has expanded its Automated Test Equipment capabilities with the addition of a new Advantest EXA Scale system.

Home » Newsroom

Eurofins EAG has expanded its Automated Test Equipment capabilities with the addition of a new Advantest EXA Scale system.

Eurofins EAG Laboratories has added the Aehr Sytems HP Tahoe Burn-In System, further enhancing its capabilities in stress testing and qualification of high-power and low-power semiconductor devices.

Eurofins EAG Laboratories has added the Teradyne UltraFLEXplus to its suite of advanced automated test equipment (ATE).

March 30 – April 3, 2025

Eurofins EAG Laboratories will be presenting a poster, Failure Analysis of Particle Contamination in Battery, at IRPS in Monterey, CA.

March 30–April 3, 2025

Eurofins EAG will be presenting a poster, Enhanced Dye and Pull for CSP Package Types, at IRPS in Monterey, California.

Eurofins EAG Laboratories, a global leader in materials testing services, is expanding its advanced microscopy capabilities with a new 6,800 square-foot laboratory in Phoenix, AZ.

EAG Scientists present research at SciX 2024 focused on compositional analysis and provenience studies of natural iron oxides pigments.

EAG Scientists presented new research about the analysis of hard rock lithium ore at Nordic Conference on Plasma Spectrochemistry in Loen, Norway.

July 29, 2024

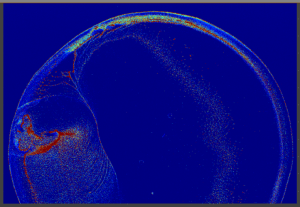

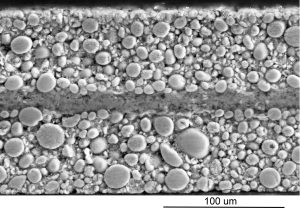

Eurofins EAG Laboratories will be presenting a poster on Machine-Learning Assisted Analysis of Battery Electrode by PFIB-SEM Tomography at Microscopy & Microanalysis on July 29th.

July 29, 2024

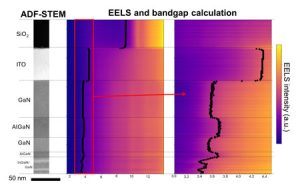

Eurofins EAG Laboratories will be presenting Automated Bandgap Measurements in Optoelectronic Devices by Monochromated Electron Energy-Loss Spectroscopy at Microscopy & Microanalysis on July 29th.

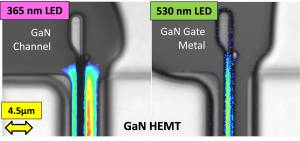

Eurofins EAG Laboratories has enhanced its thermal imaging capabilities by adding Microsanj equipment that utilizes the principles of thermoreflectance and material index of refraction to provide unmatched spatial and temporal resolution.

Eurofins | EAG Laboratories is proud to announce the expansion of its battery materials testing capabilities, with a new purpose-built 6,600 square-foot laboratory located in Sunnyvale, CA. and expanded facilities in Syracuse, New York.

May 6-10, 2024

Eurofins EAG Laboratories will be presenting “Thermal Oxide Characterization – Heat Treat Modality vs. Composition“ on May 10th. We hope to see you there!

March 4-7, 2024

Eurofins EAG Laboratories will be presenting “Characterization of Mycelium Biocomposites Under Simulated Weathering Conditions“ on March 6th. We hope to see you there!

2nd November 2023

Eurofins EAG Laboratories (EAG) expert scientist is featured speaker at Princeton seminar on careers in Surface Analysis and Material Characterization

20th September 2023

Eurofins EAG Laboratories (EAG) announced the addition of a new laser ablation system to its worldwide fleet of >2,500 instruments this week.

15th September 2023

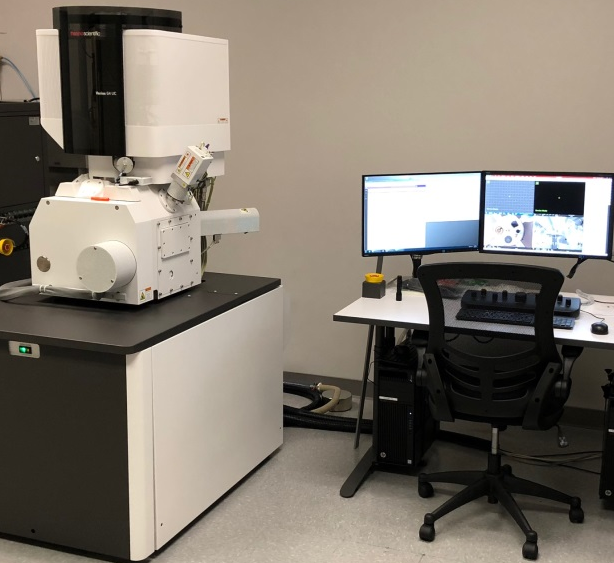

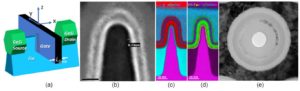

EAG Laboratories is pleased to announce a new addition to our wide range of Advanced Microscopy techniques. We now offer Plasma FIB (PFIB) services!

25th August 2023

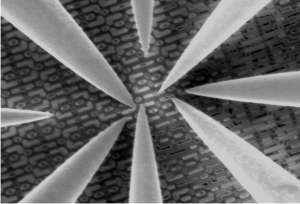

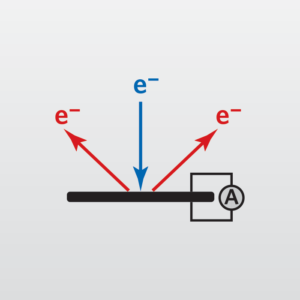

We are thrilled to announce our latest nanoprobing capabilities at EAG, powered by cutting-edge Kleindiek equipment. Nanoprobing is an advanced analytical technique that enables the direct measurement and characterization of front and backend structures.

17th July 2023

Eurofins EAG Laboratories (EAG) has recently invested in new SIMS tools to enhance small area analysis and add automation to improve throughput.

8th June 2023

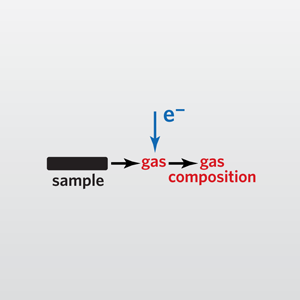

Now, with RGA included in the scope of ISO 17025, RGA testing at EAG is a premium choice to perform gas analysis.

6th June 2023

EAG Laboratories has met the requirement of ISO 27001 for managing the risks related to the security of our customers data

25th May 2023

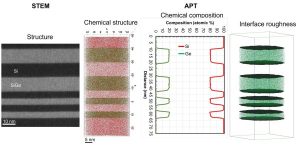

Eurofins EAG Laboratories tackled the problem of quantification of both major and minor elements in nonuniform, multi-element matrices with continuously graded composition changes using Point-by-point CORrected-SIMS.

23rd March 2023

We will be presenting and exhibiting at the 2023 TMS Annual Meeting & Exhibition in San Diego, California.

19th December 2022

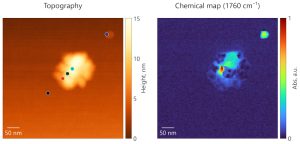

EAG Laboratories is pleased to announce a new addition to our wide range of analytical techniques. Early next year, we’ll be offering NanoIR capabilities!

17th November 2022

EAG has been approved as a suitable commercial laboratory to provide MIL-STD 883/750 Test Method 1018 Internal Water Vapor Content Testing for hermetically sealed electronic devices.

23rd October 2022

Industry Service Labs play a critical role in the battery community by providing fast and professional service. Learn how Eurofins EAG Laboratories can help!

7th October 2022

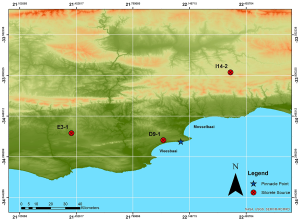

Silcrete Geological Source Discrimination with LA-ICP-MS for Minimally Destructive Archaeological Stone Tool Provenience Studies

4th October 2022

How far can we chase hydrogen? The variation reflects the effect of processing performed by base metal suppliers, storage conditions as well as methods used to control the diffusion of hydrogen.

28th September 2022

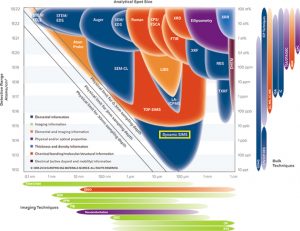

As ion implantation technology for semiconductors evolved, new metrologies to help its progress needed to be developed in parallel. Some of the current metrologies owe their present sophistication to this evolution.

20th September 2022

Dive into how scientists at Eurofins EAG Laboratories tackled the problem of quantification of both major and minor elements in non-uniform, multi-element samples with abrupt or continuously graded composition changes using PCOR-SIMS.

2nd August 2022

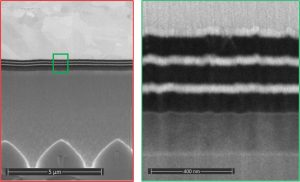

Eurofins Nanolab Technologies presented “3D Nanoscale Imaging of Semiconductor Films” at Microscopy & Microanalysis 2022

1st July 2022

Founded in 1980 Eurofins Qualitech AG, is based in Switzerland, and specializes in Materials Analysis and Non-Destructive Testing.

5th January 2022

Eurofins EAG Laboratories acquired Chip Test Solutions to expand our capacity for testing services to the Semiconductor Industry.

21st September 2021

Founded in 1993, MASER Enginering offers Reliability Test and Failure Analysis Services to the semiconductor and electronic systems industry.

10th August 2021

EAG Laboratories presented Chemical Characterization for MDR Compliance calls at MD&M West 2021 Tech Talk.

1st July 2021

Founded in 1994 as Fujitsu Analysis Laboratory Ltd, Eurofins FQL specializes in Reliability, Failure Analysis, and Material Analysis

6th May 2021

EAG Laboratories has expanded its medical device testing capabilities with a new laboratory located in St. Louis, Mo.

9th December 2020

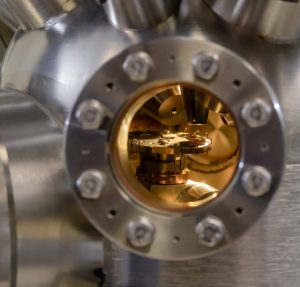

EAG Laboratories has completed installation of a ThermoFisher Scientific Themis Z Transmission Electron Microscope (TEM)

26th October 2020

EAG Laboratories presented “Advances in Characterization and Certification of Additively Manufactured Alloys and Their Feed Materials.”

11th February 2020

EAG Laboratories presented “Reduction of Particulate Matter on Medical Devices” at Medical Design & Manufacturing (MD&M) West

19th December 2019

EAG Laboratories is proud to help the Global Semiconductor Alliance incubation team assist semiconductor startups

20th October 2019

EAG Laboratories experts presented at SIMS-22, The 22nd International Conference on Secondary Ion Mass Spectrometry.

6th September 2019

Morphology and Particle Analysis measures particle size and shape along with particle chemistry, for high throughput elemental analysis.

15th August 2019

EAG Laboratories proudly announces the launch of a new laboratory in China dedicated to improving materials, products and electronics.

6th August 2019

EAG Laboratories presented “Industrial Applications of Electron Microscopy: A Shared Laboratory Perspective” at M&M 2019

29th August 2018

EBSD service with high-speed, high-sensitivity CMOS detector for direct visualization of crystal microstructure over a wide scale range.

2nd August 2018

Eurofins Acquires Nanolab Technologies, expanding Materials and Engineering Science verticals cementing presence in high-tech industries.

7th June 2018

Pernicka Corporation, a leader in internal gas composition analysis (RGA) for aerospace/defense was acquired by EAG Laboratories.

16th April 2018

Cathodoluminescence, Photoluminescence and EBIC-Scanning Electron Microscopy Analytical Services now in US with EAG Laboratories and Attolight partnership.

6th March 2018

Eurofins acquires EAG Laboratories, providing an entry into growing Materials and Engineering Sciences markets, and adding key Life Science capabilities.

5th December 2018

SEM images from EAG scientist Sheri Neva recently won three awards from the International Metallographic Society, featuring metallurgical analysis.

12th July 2016

Introducing EAG Laboratories, combining technology and life-science brands to leverage full breadth of contract research and testing capabilities.

15th May 2015

Electronics failure analysis services from EAG extended with millions in new tool investments, adding latest precision imaging and inspection equipment.

To enable certain features and improve your experience with us, this site stores cookies on your computer. Please click Continue to provide your authorization and permanently remove this message.

To find out more, please see our privacy policy.