Particle Analysis Services

Home » Particle Analysis Services

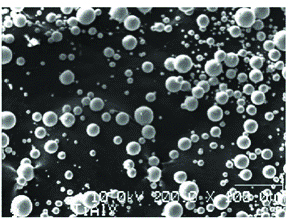

Particle analysis and particle identification services from EAG Laboratories can help you determine the root cause of a product problem and evaluate corrective actions. Particulate material commonly shows up in raw materials, in-process samples, and finished products.

EAG’s scientists have identified many types of particulates found in (or on) coatings, plastics, food, consumer products, chemicals, pharmaceuticals, medical devices, semiconductors, consumer products, additives, adhesives and more.

Our particle analysis services labs have identified such materials as:

- Black specks in a white powder

- Particles in a bottle of pills

- A fine suspension of particles in a bottle of liquid

- Surface contamination

EAG Laboratories has developed expertise in identifying and characterizing particles of an unknown origin with individual and combined compositional analysis techniques in conjunction with expert data interpretation. We have developed a proprietary library of FTIR, LC-MS and GC-MS spectra to speed particle identification investigations.

We have used many different particle analysis techniques, including Fourier Transform Infrared Spectroscopy (FTIR), Raman Spectrometry, Auger Electron Spectroscopy, X-Ray Photoelectron Spectroscopy (XPS), X-Ray Fluorescence (XRF) and scanning electron microscopy-energy dispersive X-ray spectroscopy (SEM-EDS).

Once we determine the chemical nature of the particulate material, it may become important to gain a better understanding of the composition through further material characterization.

Armed with a particle analysis, we help our clients to:

- Determine the potential source of the identified material

- Compare the chemistries of two different particulates

- Confirm the identity of a suspected material

The technique of choice for compositional analysis depends on many factors:

- What is known about the sample already?

- What needs to be quantified (major elements, minor elements, chemical components, or molecular/organic components)?

- Can destructive test methods be used?

- Is the sample unique?

Surface Analysis

Elemental and chemical surface compositions are best measured using quantitative techniques with shallow information depths (<100Å), such as Auger Electron Spectroscopy (typically conductive materials only) or X-Ray Photoelectron Spectroscopy (all materials).

Bulk Analysis

Bulk composition is best determined with techniques that have large/deep information depths that ignore potential compositional variations at/on surfaces. Depth-specific information is typically not available with these methods. X-Ray Fluorescence (XRF) and scanning electron microscopy-energy dispersive X-ray spectroscopy (SEM-EDS) are non-destructive techniques that can provide elemental composition. Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES) can quantify both major and minor elemental components. Fourier Transform Infrared Spectroscopy (FTIR) and Raman Spectroscopy are well suited to identify plastics, polymers and other organic materials.

Would you like to learn more about Particle Analysis Services?

Contact us today for your particle analysis needs. Please complete the form below to have an EAG expert contact you.