UV-C Irradiation For Product Reliability Testing

Home » UV-C Irradiation For Product Reliability Testing

Ultraviolet light (UV-C) is used for the disinfection of surfaces, air and water. It is able to destroy the outer protein coating of viruses and may therefore be effective in killing the SARS-CoV-2 virus, which causes COVID-19. UV-C radiation is applied on surfaces to mitigate the risk of acquiring an infection. However, frequent irradiation of polymer products and coatings with UV-C light may reduce product lifetime. Dedicated test set-ups are offered to gain understanding on failure modes and product lifetime optimization.

ULTRAVIOLET RADIATION FOR DISINFECTION

Ultraviolet radiation is electromagnetic radiation with wavelengths between 100nm and 400 nm. This segment is divided into three parts:

- UV-A: 315 – 400 nm

- UV-B: 280 – 315 nm

- UV-C: 100 – 280 nm

UV-A and UV-B are parts of the solar-spectrum and can be found in the atmosphere. UV-C is also a part of the solar spectrum, but it is blocked by the ozone-layer and therefore not present in the atmosphere on earth. Compared to UV-A and UV-B, UV-C is more effective as a germicide because of its high energy.

UV-C is generally applied for water, air and surface disinfection. It has been used in hospitals for years, but currently the application of UV-C gains interest for the disinfection of classrooms and other public places.

POSSIBLE SIDE-EFFECTS OF UV-C IRRADIATION ON PRODUCT QUALITY

But what impact does UV-C irradiation have on products exposed to this kind of UV light? Many products are made out of plastic or have housings containing polymers. It is well known that most polymers degrade upon irradiation with UV-C light, as the irradiation can break chemical bonds.

What are the effects on materials due to UV-C and what does this mean for the lifetime of a polymer, plastic coating or assembly? At present, not much is known about the degradation of materials due to UV-C.

Possible effects of UV-C radiation on plastics:

- increased brittleness

- a change of color

- increased surface roughness

- change of wetting behavior of liquid disinfection agents (spray / impregnated wipes)

Ultimately, UV-C related material degradation can, in addition to visual deviations, lead to accelerated fatigue of products and to unreliable components.

GAINING INSIGHT INTO POSSIBLE DEGRADATION

The degree of degradation upon UV irradiation strongly depends on the polymer used. Small differences in the formulation of the polymer blend can have large effects. In addition, the intensity of the UV-C light used for disinfection is relatively high and the spectrum is totally different from solar light.

Eurofins Materials Science Netherlands B.V. designs customer specific test protocols and can execute relevant tests in dedicated UV-C equipment. By using reliability models, the UV-C test results can be used to predict the lifetime of the product/material under investigation.

In addition, using our portfolio of chemical analysis techniques the underlying failure mechanism can be investigated, allowing for solutions towards longer product lifetimes.

THE FULL SPECTRUM OF UV TEST CAPABILITIES

Eurofins Materials Science Netherlands B.V. offers a complete package for testing. Besides conducting tests with UV-C, there are also options for testing using UV-A, UV-B and sunlight.

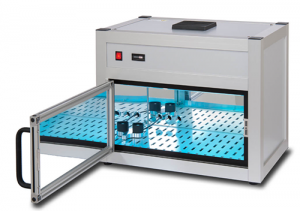

THE IRRADIATION CHAMBER

The irradiation chamber (Figure 1) is compact and robust for time- and/or dose-controlled irradiation of samples with UV or visible light. Materials can be exposed to UV-C, UV-B, UV-A, or daylight D65 to achieve the highest irradiance.

Would you like to learn more about UV-C Irradiation For Product Reliability Testing?

Contact us today for your UV-C irradiation for product reliability testing needs. Please complete the form below to have an EAG expert contact you.