Surface Analysis

Home » Services » Materials Testing & Analysis » Surface Analysis

EAG scientists are experts in surface analysis, including the various factors that affect surface chemistry and other surface-specific properties. When surface information is needed, we determine the most relevant analytical approach to obtain the best results. Our laboratories employ different surface analysis and surface characterization techniques to investigate and understand the issues associated with surface coverage, molecular orientation, functionalization, contamination, and surface segregation.

The chemistry of the upper monolayer of a surface can have a dramatic effect on surface wetting, biocompatibility, reactivity, and adhesion. For example, plasma processing and other gas-phase treatments are routinely used to alter the near-surface chemistry of polymer films prior to printing or adhesion steps. Similarly, organic silanes and thiol-terminated self-assembled monolayers can be applied from solution to modify the surface chemistry of glasses and metals.

EAG’s materials surface analysis laboratory solves issues with adhesion and bonding, questions regarding surface cleanliness and investigations regarding morphology and topography of materials’ surfaces.

Adhesion & Bonding

Adhesion involves joining two or more surfaces together. Surface analysis investigations may focus on problems with both adhesion and bonding. Failures can occur when contaminants are introduced into the process, or if the adhesive components are formulated incorrectly. Many different failure modes and causes of failures can exist for different materials systems.

- For polymer packaging, surface pretreatments and organic coatings, failures may occur due to contaminants in or on the joining surfaces. If an adhesive is used, failures may also occur.

- In the case of metallic lead failure in microelectronics, the cause may be due to impurities, an oxide layer or buried species that diffuse to the adhering surfaces during or after bonding.

Uncovering the source of adhesion and bonding problems in surface analysis lab investigations can require the use of very surface-sensitive analytical tools. If possible, the failure site should be investigated by examining both sides of the delaminated interface.

Cleanliness

Assessing surface cleanliness can involve a range of different measurement approaches, depending on the surface and material of interest. It may also involve comparing samples that were processed differently or exposed to different environments. Differences between the test sample and the control or reference sample are often best highlighted by this approach. For example a very sensitive measurement may reveal that cleaning chemicals left residues behind because they were not rinsed off properly. A less sensitive measurement technique may not have detected the residue, or may not have had sufficient signal to fully identify it.

Assessing cleanliness generally requires some understanding of the possible sources of the contaminants:

- Are elemental or molecular contaminants of interest?

- Is the presence or absence of material to be confirmed?

- Is there a specific concentration level that species of interest must be below?

Related Resources

- Webinar: Surface Analysis

- App Note: Identification of Contamination Using AES

- App Note: AFM: Polymer Surface Modification

- App Note: Organic Contamination on Surfaces

- App Note: Characterization of Surface Contamination

- App Note: Contact Lenses: Understanding Surface Chemistry

- App Note: Surface and Interface Characterization of Polymers

- Blog: Is my surface clean?

- Industry: Energy

- Industry: Medical Devices

- Industry: Semiconductors

Investigating very clean surfaces may require techniques that have detection limits in the parts-per-million range, such as Total Reflection X-ray Fluorescence (TXRF), which detects elemental species only, or Time-of-Flight Secondary Ion Mass Spectrometry (TOF-SIMS), which looks at both elemental and molecular species. In cases where cleanliness is measured by the number of particles on the surface, Scanning Electron Microscopy (SEM) may be a good option, for both surface imaging and particle counting.

Morphology & Topography

Morphology is the qualitative evaluation of the three-dimensional shape of a surface, whereas topography provides quantitative feature dimensions. The choice of surface characterization analytical technique depends on whether qualitative and/or quantitative information is required.

Morphology, or “what a sample looks like,” is best evaluated using imaging techniques, such as optical microscopy or Scanning Electron Microscopy (SEM). These methods can also provide layer thickness and other quantitative information.

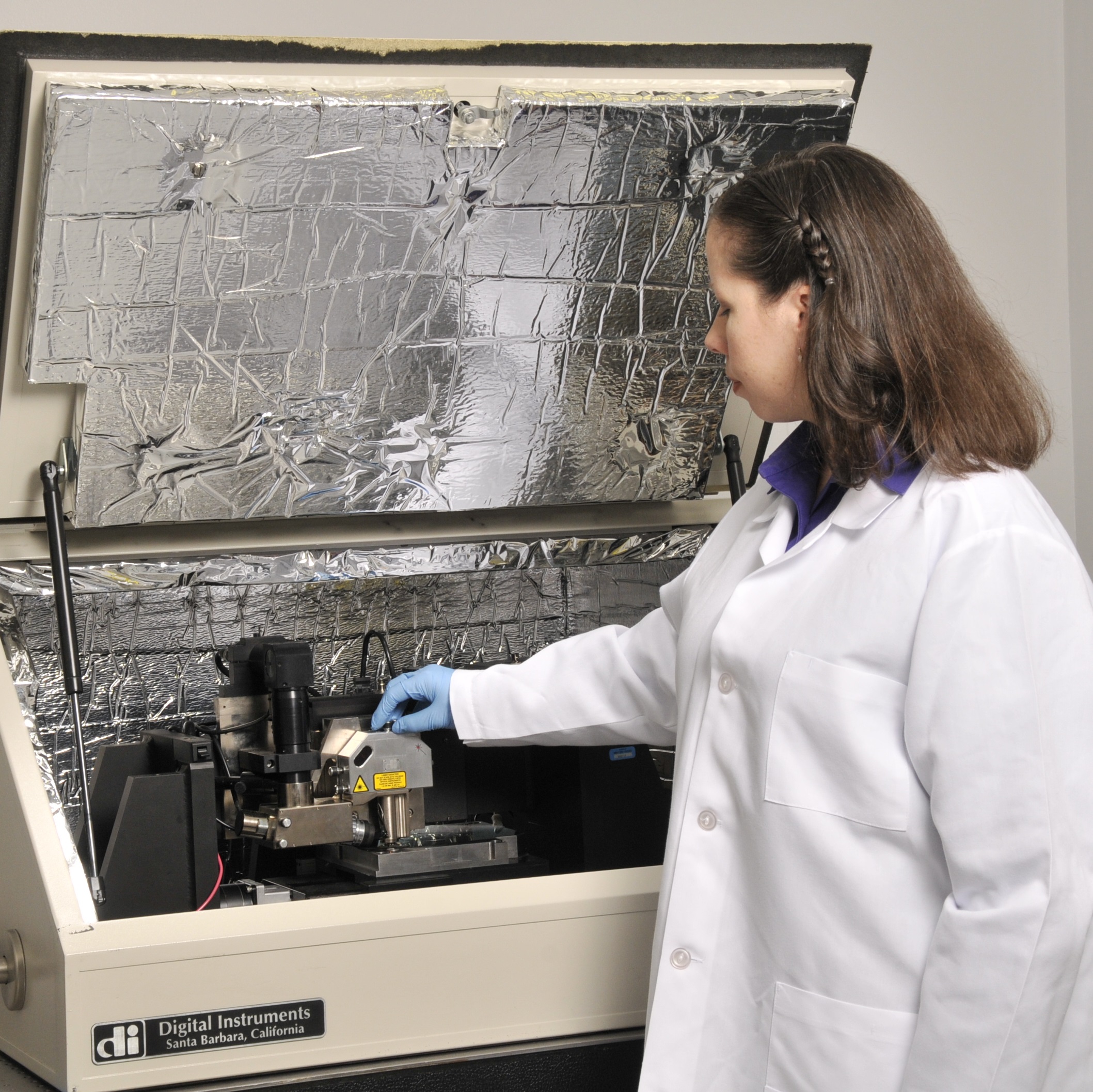

Topography, including various measures of roughness, step heights, dimension and feature size can be addressed using Atomic Force Microscopy (AFM), Optical Profilometry (OP) or Stylus Profilometry.

Would you like to learn more about Surface Analysis?

Contact us today for your Surface Analysis needs. Please complete the form below to have an EAG expert contact you.