Glass defect analysis

Home » Glass defect analysis

Definition of a glass defect: “A glass defect is an enclosure in a glass object with different optical and/or other properties”

Glass faults or defects are inherent to the glass production process. Glass melting is a complex process and it is often impossible to create the ideal conditions for “smooth” glass melting. Technologists have to cope with several issues, like raw materials, “strange” cullet, refractory corrosion (i.e. degradation of the materials the glass tank is composed of), and much more.

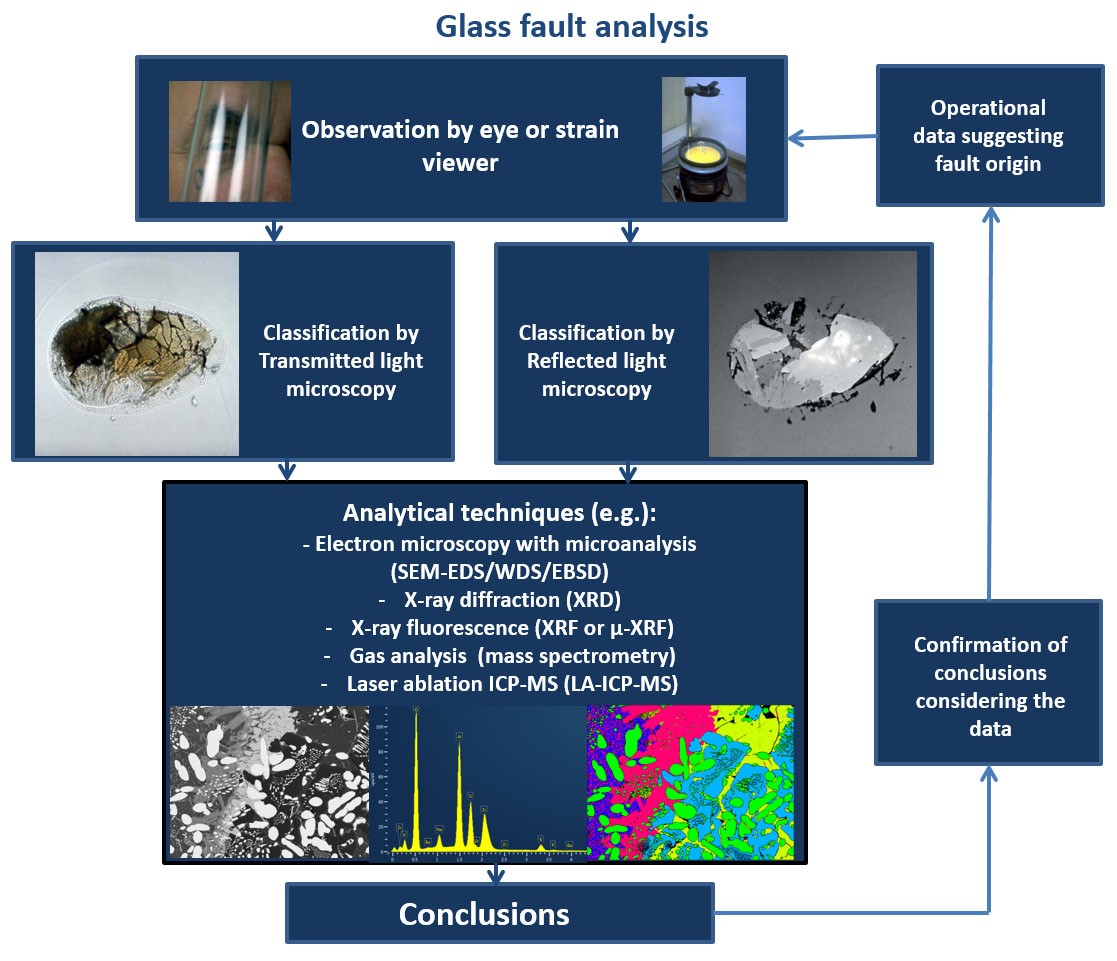

A glass defect can originate from many different sources like disturbances in the melting process, devitrification or corrosion of refractory material. In order to identify the source of a glass defect, a broad range of inspection techniques can be used.

Analysis of the defects in combination with operational data can be valuable to decrease or eliminate the number of defects.

Classification of defects; a systematic approach

A first classification of defects can be made by analyzing the defect by eye, magnifier or microscope.

When this is insufficient, glass defects can be prepared for more advanced analytical techniques. These techniques provide additional information like chemical composition or crystalline structure of the defect.

While combining this information with operational data and data sheets, adjustments to the glass production process can be made which will eventually reduce or eliminate the source of glass defects. The figure above summarizes a typical analysis routine.

Inspection techniques for glass defects

Eye / magnifying glass or loupe

The naked eye and a magnifier are the first steps that allow observation of the type of defect: inclusion (i.e. stone, cords), crack or bubbles. In case of an inclusion, the degree of inhomogeneity around a defect, shape, color, opacity or transparency of a stone can be investigated.

All these observations are a useful basis for classification of a glass fault. Other analytical techniques should often be applied to determine the origin of the fault.

Polariscope

Stresses are built up in the glass due to inhomogeneity surrounding defects or difference in thermal expansion. Those stresses can be made visible using a polariscope.

As altitude and sign of these stresses depend on the nature of the inhomogeneity, it can provide some information on its composition and/or origin.

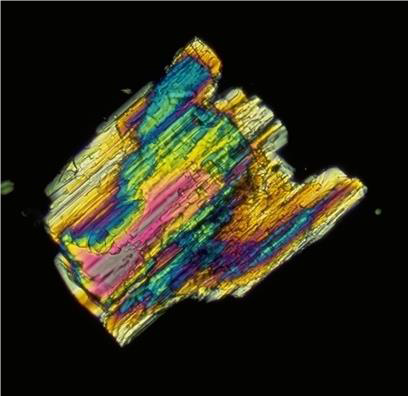

Microscope using transmitted /polarized light

The optical microscope is useful to examine transparent defects. By using polarized light, phase differences caused by cords and crystals pop up. Crystals, structure, shape, stress and size give important information about the composition and possible origin of a glass fault.

Elemental and chemical analysis of defects in glass

As indicated in the diagram of analysis routines, the next step after optical inspection can be an additional study to investigate the composition of solid inclusions, gas bubbles or homogeneously distributed dopant. EAG has a large portfolio of techniques to address this.

Would you like to learn more about Glass defect analysis?

Contact us today for your glass defect analysis needs. Please complete the form below to have an EAG expert contact you.