XRD Webinar

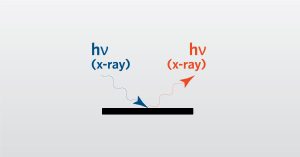

In this webinar we introduce X-ray Diffraction (XRD) which is a analytical technique for the examination of crystalline materials.

To enable certain features and improve your experience with us, this site stores cookies on your computer. Please click Continue to provide your authorization and permanently remove this message.

To find out more, please see our privacy policy.