Analyzing Vertical Cavity Surface Emitting Lasers Webinar

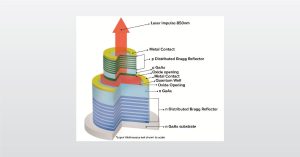

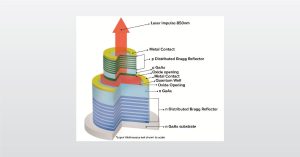

In the full webinar we will introduce analyzing VCSELs with a focus on secondary ion mass spectrometry (SIMS)

Home » When Images Aren’t Enough – EDS and EELS

The use of advanced materials and the miniaturization of technology have driven the need and requirements for analytical testing. Materials and end products need testing throughout their lifecycle, from development to failure analysis. For industries, such as semiconductors, compound semiconductors and batteries, a high-resolution image is a great first-look at the sample.

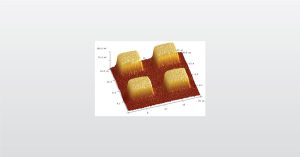

Scanning Electron Microscopy (SEM) provides high-resolution and high-depth-of-field images of the sample surface. SEM is one of the most widely used analytical tools, due to the extremely detailed images it can quickly provide. Transmission Electron Microscopy (TEM) and Scanning Transmission Electron Microscopy (STEM), using higher energy electron beam which transmits through the specimen, have better spatial resolution than SEM but often require more complex sample preparation.

But what if images aren’t enough? Energy Dispersive X-ray Spectroscopy (EDS) and Electron Energy Loss Spectroscopy (EELS) can help provide complementary information along with images.

Both EDS and EELS are techniques that can provide elemental identification. EDS can be coupled with all SEM and STEM imaging techniques to determine the elemental composition of individual points, line scans or map the spatial distribution and segregation of elements from the imaged area. EELS provides elemental information on the nanometer scale when used with TEM and STEM.

One of the key differences between the two techniques is that EDS is better suited for survey analysis to see what elements are present, while EELS can provide more detailed information on phases and bonding. Although both techniques can reach sub nm resolution, compared to EDS, EELS provides improved signal to noise, better spatial resolution, higher energy resolution (<1 eV), increased sensitivity to the lower atomic number elements; and although both techniques can reach sub nm spatial resolution, EELS provides better spatial resolution. However, some understanding of the material is needed for a successful analysis. In addition, there are specific sample requirements for STEM/EELS, whereby, a really thin sample (lamella) is needed to ensure that the electron beam goes through the sample. EDS can be considered more straight forward analysis.

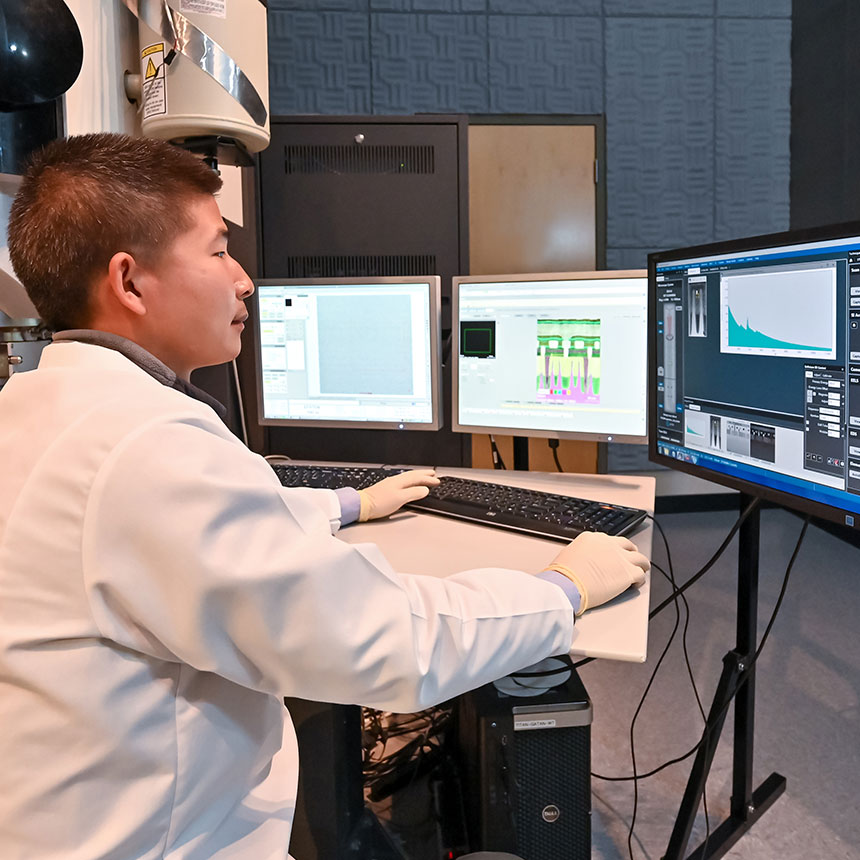

Here’s an example of how an analysis job can transfer from SEM/EDS to TEM/EELS.

A client comes to us regarding contamination on a surface. A first step may be top-down SEM for an initial image and then EDS to determine the elements. After SEM analysis, we discover two types of particles, one larger in size and the other really small. The smaller particle would need additional analysis on the TEM. EDS is still used to find out which elements are in the particle. Carbon is found so they would need EELS to specify what type of carbon is present.

As structures decrease in size and the use of lighter elements increases, the need for EELS has also grown. With the advancement of batteries, EELS analysis at the nanometer scale has greatly improved development processes. With products such as LEDs, EDS is sufficient to look at composition of active regions and quantum wells.

So which technique has better detection sensitivity? This depends on the elements you are trying to detect. When it comes to semiconductor residue such as fluorine, chlorine, bromine, phosphorous, and iodine, EDS has better sensitivity. While EELS performs better when detecting lithium, boron, carbon, nitrogen and oxygen.

At Eurofins EAG, we are your trusted partner in advanced microscopy analysis. We have the most advanced EDS and EELS systems and have decades of experience in both techniques. Our network of experts has years of experience working with a multitude of materials and industries. Contact us today to learn how we can help you on your next project.

In the full webinar we will introduce analyzing VCSELs with a focus on secondary ion mass spectrometry (SIMS)

In this webinar will be presenting information on scanning Microwave Impedance Microscopy (sMIM) operation.

EAG Scientists utilize GDMS analysis to perform Elemental Depth Profiling for chemical purity evaluations for aerospace & defense.

Wednesday, May 14, 2025

This webinar will cover the chemical characterization of consumer products using extractable/leachable studies. Register to reserve your spot today!

To enable certain features and improve your experience with us, this site stores cookies on your computer. Please click Continue to provide your authorization and permanently remove this message.

To find out more, please see our privacy policy.