Ask the Expert: ESD

Damage caused by ESD is one of the primary failure mechanisms for integrated circuits. Testing susceptibility to ESD events is crucial in the success of electronic devices and is essential for the qualification process.

Home » The Versatility and Usefulness of Aerogels

Thermal resistance and its complement, thermal conductance, are fundamental concepts in thermodynamics, thermal engineering, and heat transfer. They describe the ability of a material to insulate (resistance) or transfer (conductance) heat. Thermal resistivity is important in industries like aerospace, automotive, building &

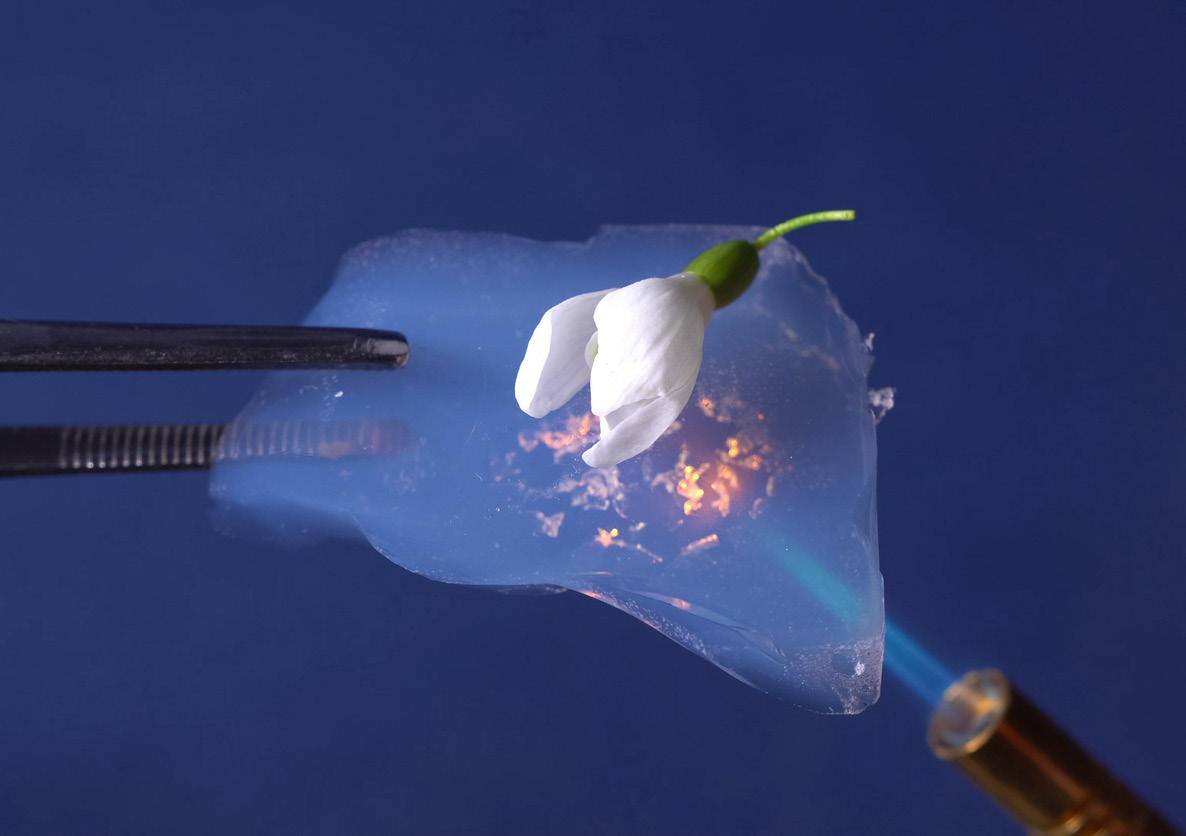

construction, biomedical applications, and energy storage, among others. At one end of the spectrum of thermal properties are metals which typically exhibit high conductance and low resistance, for example, a copper coil immersion chiller used to transfer heat out of a liquid. At the other end of the spectrum are thermal insulators like fiberglass and polyurethane foam. There are, however, more exotic materials that exhibit more extreme properties. Diamond and boron arsenide are both much more conductive than the most conductive metal – silver. Silica aerogel is about 33% less conductive than

expanded polyurethane foam (The Engineering ToolBox). Aside from being exceptional insulators, aerogels have other fascinating properties that make them well-suited for unique applications.

Due to their unusual features, aerogels can be used for biomedical, acoustic, food packaging, electrochemical energy storage, thermal insulation, environmental, water treatment, catalysis, and aerospace applications. For biomedical and pharmaceutical applications specifically, aerogels can be used for diagnostic instruments, implantable devices, biosensing, wound repair, regenerative medicine, and delivery of medications. In astronautical applications, aerogels have a variety of uses including thermal insulation, high-velocity particle capture (e.g, cosmic dust collection), cryogenic fluid containment, fire retardation, acoustics, thermal barriers, etc. (Nazia Rodoshi Khan, 2024).

A research group from the Hefei Institutes of Physical Science of the Chinese Academy of Sciences recently developed aerogel materials with higher temperature resistance, strength, and insulation performance. Aerogels are traditionally made with SiO2, but in this group’s study, researchers introduced small amounts of ZrO2 crystalline phase to one-dimensional SiO2 fibers (Liu Cui, 2024), which increased their temperature resistance. Additionally, they investigated the potential use of biomass aerogels for eco-friendly building insulation materials, developing sodium alginate aerogels that were able to support 2600 times their own weight and possessed flame retardancy and self-extinguishing properties. This recent research has helped provide solutions for efficient heat insulation.

The characterization of synthesized aerogels typically emphasizes structural and materials properties rather than elemental or molecular composition. EAG is well-equipped to undertake Surface Area (Brunauer, Emmett and Teller equation) and Pore Size Determination (Barrett, Joyner, Halenda or Density Functional Theory methods) measurements of aerogels. For aerogels that are being deployed for purposes such as capturing high-velocity particles in a spacecraft or carrying calcium, zinc and silver cations for wound care, mapping the distribution of chemical composition is an important application. Scanning Electron Microscopy – Energy Dispersive Spectroscopy and Laser Ablation – Inductively Coupled Plasma – Mass Spectrometry are both spatially resolved elemental chemistry techniques well-suited to mapping aerogels. Bulk compositional analysis of aerogels, such as before and after testing of aerogels used to harvest uranium from sea water, can be accomplished using Inductively Coupled Plasma – Optical Emission Spectroscopy or Inductively Coupled Plasma – Mass Spectrometry. EAG scientists and engineers are ready to work with you to develop application-specific protocols to meet your aerogel needs.

Damage caused by ESD is one of the primary failure mechanisms for integrated circuits. Testing susceptibility to ESD events is crucial in the success of electronic devices and is essential for the qualification process.

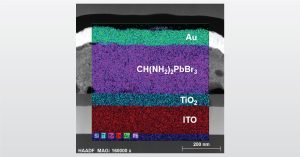

In this webinar we introduce Advanced Focused Ion Beam (FIB) which provides precise cross-section imaging analysis

In the full webinar we will discuss Thin Film Analysis that looks at film composition, thickness, and uniformity.

For 3D printed products, XPS can provide composition and bonding information for the top 5-10nm sample surfaces. Oftentimes, surface contamination/oxide thickness would affect the appearance (as well as performance when applicable) of the material, and XPS could help identify the source and/or cause.

To enable certain features and improve your experience with us, this site stores cookies on your computer. Please click Continue to provide your authorization and permanently remove this message.

To find out more, please see our privacy policy.