When Innovation Meets Failure Analysis

In our interconnected and changing world, it is important to know how to respond to potential electronic system failures.

Home » The Importance of VCSELs in Technological Development

VCSELs were first commercialized in 1996. Examples of applications in the last 20+ years have been high speed data communications on optical fiber, laser printers, the computer mouse, night vision cameras, etc. Recently, VCSELs have been used for LIDAR (light imaging detection and ranging), 3D sensing and facial recognition. A VCSEL has several advantages such as a higher modulation speed, on-wafer testing and the emission of a symmetrical emission pattern that is oriented perpendicular to the surface. This form of emission is ideal for coupling into other optical components.1

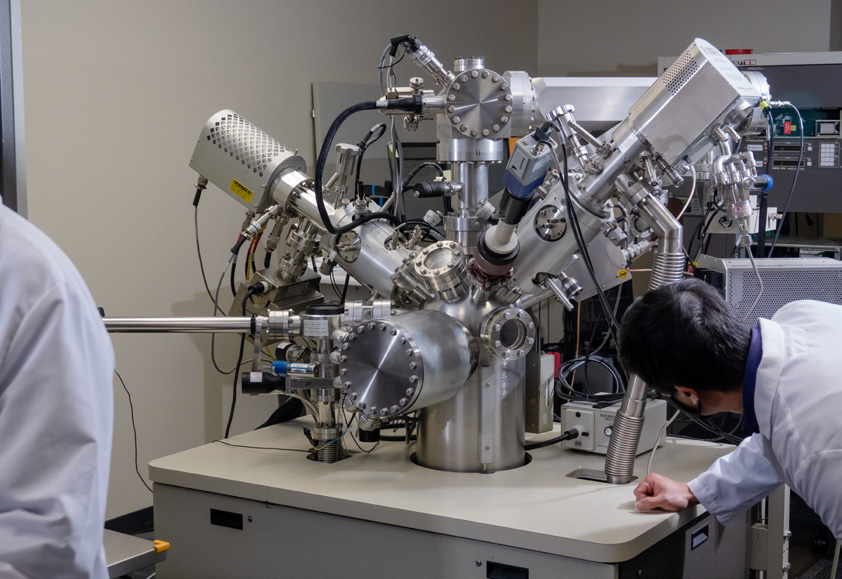

The characterization of VCSELs did not come easily and has evolved over time. One of the biggest challenges associated with the application of Secondary Ion Mass Spectrometry (SIMS) to the analysis of AlGaAs/GaAs VCSELs is the variation in aluminum content impacting the quantification of dopant elements. This means that quantitative analysis requires sophisticated calibration for dopant concentrations and layer thicknesses in layers where % aluminum varies.

With the development of PCOR-SIMSSM by EAG scientists, these issues were addressed by employing empirically derived analytical functions to correct for the well-known ‘SIMS matrix effect’, which comes into play when one deals with materials that are dissimilar in nature.1

Through close interactions with our clients, Eurofins EAG (EAG) scientists came to know that low concentrations of unwanted contaminant species were just as important. These impurities can be detrimental to device performance or lifetime, even at very low (≤ppm) concentrations. This led EAG scientists to develop special instrumentation and analytical protocols to achieve record level detection limits to be able to do reliable contamination evaluation. The most common impurities are hydrogen, oxygen, sulfur, and copper, which may be present as contamination spikes at interfaces or crystal defect regions. When trying to isolate and eliminate the source of contamination, knowing the exact location of these impurity spikes in the layer growth sequence is also important. Therefore, appropriate selection of matrix markers, acquired in accurate synchronization with impurity elements, during SIMS data collection is crucial.

Lastly, PCOR-SIMSSM can also offer detailed insights into the active region of the structure where the light is generated. PCOR-SIMSSM can reveal the concentration gradients of the aluminum profile with depth, MQW layer evaluation and dopant or impurity analysis with nm resolution, all with quantitative accuracy over the entire range of grown Al compositions.

At EAG we are ready to help you scrutinize and analyze your VCSEL structure. We understand the importance of alloy composition profile, DBR dopant profiles and various intricate details associated with the active layer. Contact us today to learn more about our analytical capabilities as they relate to VCSELs.

In our interconnected and changing world, it is important to know how to respond to potential electronic system failures.

During this live Ask the Expert event, we will answer pre-submitted questions from our audience regarding materials analysis with various surface contact and optical analytical techniques.

There are many key components of the VCSEL, but one challenging region is the oxide aperture. The oxide aperture is responsible for current confinement, and it is important to have high quality oxidation to prevent failure of the device.

May 15, 2024

Check out our online symposium presented by EAG Laboratories and Exponent!

To enable certain features and improve your experience with us, this site stores cookies on your computer. Please click Continue to provide your authorization and permanently remove this message.

To find out more, please see our privacy policy.