Warpage Analysis Webinar

In this webinar we introduce Warpage and Strain Characterization used for non-contact, full-field acquisition of 3D topographies.

Home » Surface Characterization of Antibacterial Coated Sutures

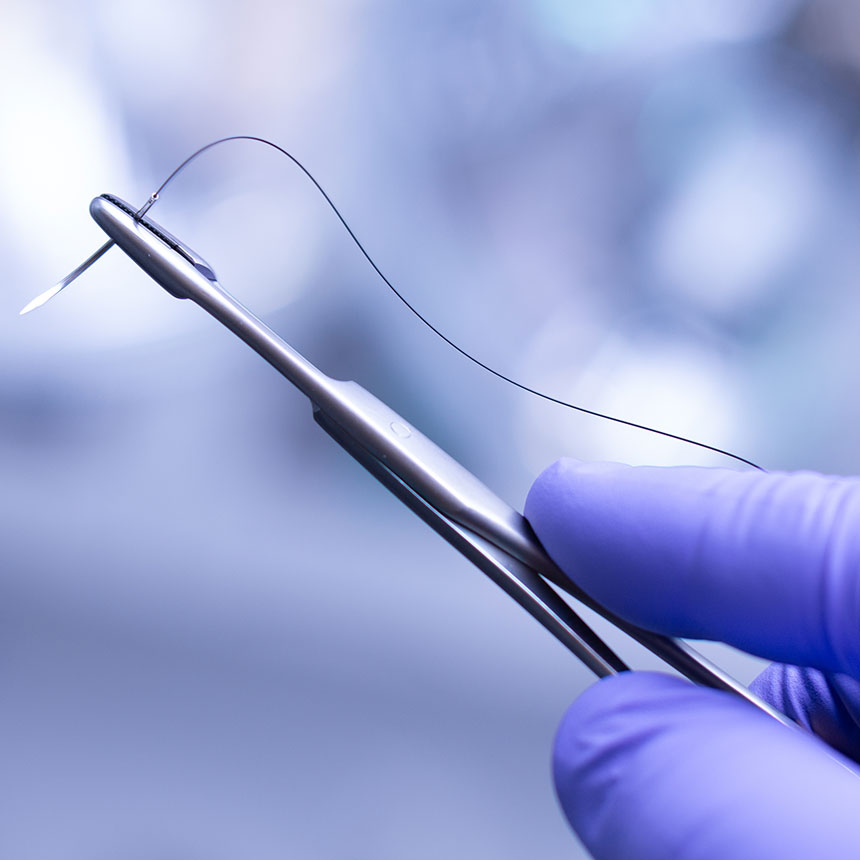

Remember years ago, when the term ‘antibacterial’ was mainly associated with an ointment to lather on to a cut or scrape? Nowadays, from ointment and wipes to body wash and lotion, you see antibacterial products everywhere! When I hear ‘antibacterial,’ the first thing that comes to mind is germ-fighting. In the medical industry, being germ-free and infection-free is obviously of utmost importance!

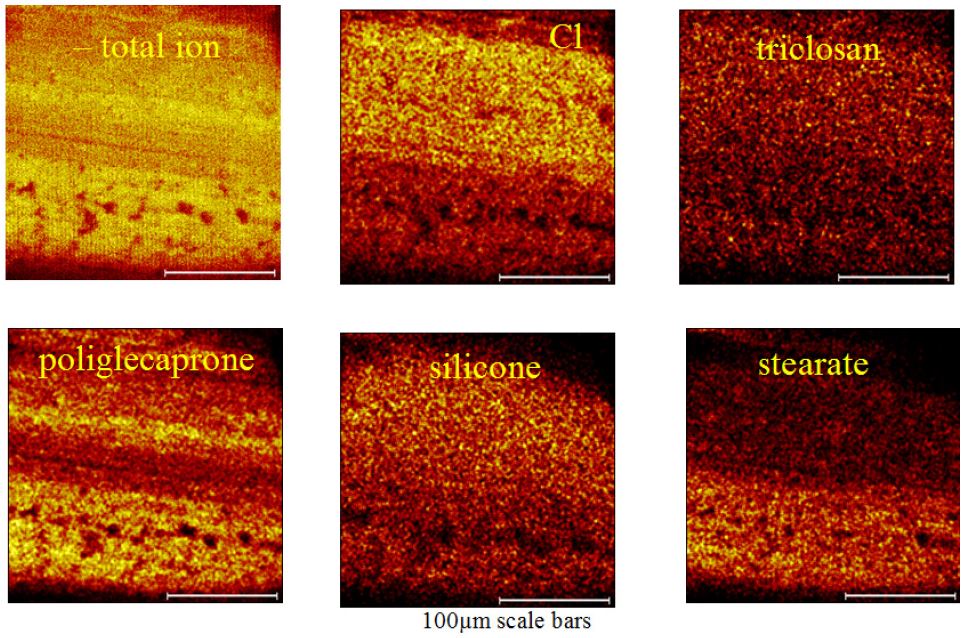

Surgical site infections (SSI) are caused by germs and bacteria. This is something that always needs to be monitored post-surgery. What do doctors tend to say? “Be sure to keep the area clean and change bandages often”. Cleanliness throughout the surgical process is one of the ways to prevent infection. Another way to reduce the occurrence of SSI is the use of antibacterial coated sutures. Triclosan has been used in coatings on poliglecaprone based sutures. Understanding the surfaces of suture coatings is important for failure analysis and quality control.

There are some materials that are more volatile in certain temperatures or environments, whereby, a special type of analysis needs to be performed. Triclosan is one of those materials. Time-of-Flight Secondary Ion Mass Spectrometry (TOF-SIMS) and X-ray

Photoelectron Spectroscopy (XPS) are well-known techniques for surface analysis; however, the vacuum systems used in these instruments would not work with Triclosan since it would evaporate at such low operating pressures. Fortunately, at EAG, we offer a solution!

Cold stage analysis has been shown to be effective for samples that are not solids at room temperature or that have components that are volatile in a vacuum system, such as the antibacterial coated sutures. Samples can be cooled to near liquid nitrogen temperatures outside the vacuum system and then pumped down to UHV pressures for analysis. At EAG we offer cold stage analysis options for TOF-SIMS and XPS. XPS provides a semi-quantitative measurement, while TOF-SIMS is only relatively quantitative but more chemically specific. Both techniques can provide a picture of the triclosan distribution on the surface of the sutures. (download application note)

With many years of experience at Eurofins EAG, our technical experts have been exposed to a wide variety of failure analysis and quality control problems in all industries. With our breadth of techniques and customized approaches, we work with our clients to help identify and solve their problems.

Contact us today to learn how we can help you on your next project.

In this webinar we introduce Warpage and Strain Characterization used for non-contact, full-field acquisition of 3D topographies.

Measuring the chemical state of the battery components such as the cathode, anode, separator, electrolyte, contact layers and additives, at various stages of cycling, provides vital information about the electrochemical processes that occur during battery use.

During this Ask the Expert webinar, our team of battery materials experts will address your pre-submitted questions during the event, as well as present about our new battery lab’s capabilities.

In this webinar we show how EAG troubleshoots electronic system failures using a multidisciplinary approach

To enable certain features and improve your experience with us, this site stores cookies on your computer. Please click Continue to provide your authorization and permanently remove this message.

To find out more, please see our privacy policy.