Uniformity is Key in Epitaxial Growth

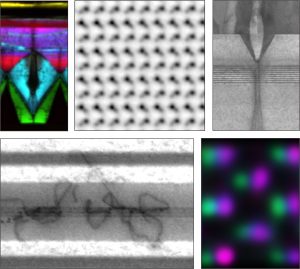

AC-STEM analysis can provide a visual representation of non-uniformities in an active region. Roughness can easily be observed within interfaces. EDS maps can then be used to corroborate the roughness in relation to composition.