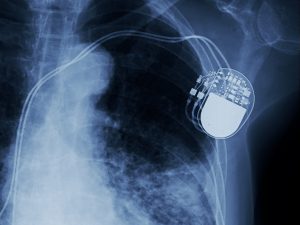

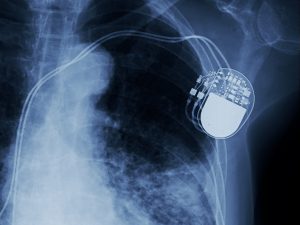

Failure Analysis of Medical Device Electronics

As medical devices become more complex, there are many more opportunities for things to go awry. Identifying, diagnosing, and remedying failures becomes dramatically more challenging. We can help.

Home » Delamination of Food Packaging

The global food packaging market is projected to grow from $338.34 billion in 2021 to $478.18 billion in 2028 at a CAGR rate of 5.1%. Food packaging is used for a variety of purposes including contamination protection, convenience, and portion control.

A client wanted to investigate the failure of a multilayer laminate used for food packaging. Lots of roll stock did not meet the seal strength specification; bad lots exhibited seal strengths that were an order of magnitude lower than the known good lots.

Cross-sections of samples from the seal strength test were prepared using a cryo-microtome. The failure location for samples analyzed from good and bad lots were different; laminates that failed the test exhibited a mixed mode failure of the adhesive between polyolefin and polyester layers, whereas laminate that passed the test delaminated between the foil and polyester layers. Based on pyrolysis GC-MS of the adhesive, polyurethane species were detected in the desorption step for the bad lots and only in the pyrolysis step for the good lots. In addition, the adhesive from the bad lots had lower average molecular weight values and a higher polydispersity index.

Results indicate that the reduced seal strength was due to degraded adhesive in the bad laminate lots.

For more than 50 years, scientists and engineers at Eurofins EAG have investigated and resolved product failures for clients. Our team of experts identify key failure indicators and follow them to the root cause.

Failure analysis of plastics, thermosets, and rubber materials is commonly performed on finished products and typically involve comparative analysis between failed and non-failed samples. Once the potential root cause is identified, experiments can be designed and conducted to test the hypothesis and recreate the failure in the laboratory. Eurofins EAG can evaluate a variety of polymer types, including:

Eurofins EAG Laboratories offers a full suite of analytical techniques to evaluate the identity, composition, morphology, topography, and rheology of polymeric materials and components.

Call +1 800-366-3867 or email us.

As medical devices become more complex, there are many more opportunities for things to go awry. Identifying, diagnosing, and remedying failures becomes dramatically more challenging. We can help.

A device manufacturer observed defects in a lot of thermoplastic tubing. The tubing exhibited signs chemical attack or exposure to heating.

Electrical AFM can measure the electrical/electromechanical properties of various functional materials and samples. This helps distinguish between conductive and nonconductive areas or polar and nonpolar regions of a device.

In sectors like the automotive industry, ATE plays a pivotal role in verifying the proper and reliable operation of critical systems.

To enable certain features and improve your experience with us, this site stores cookies on your computer. Please click Continue to provide your authorization and permanently remove this message.

To find out more, please see our privacy policy.