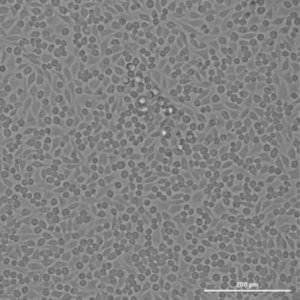

The Conspicuous Case of the Missing T0 in ISO 10993-5 Cytotoxicity Testing

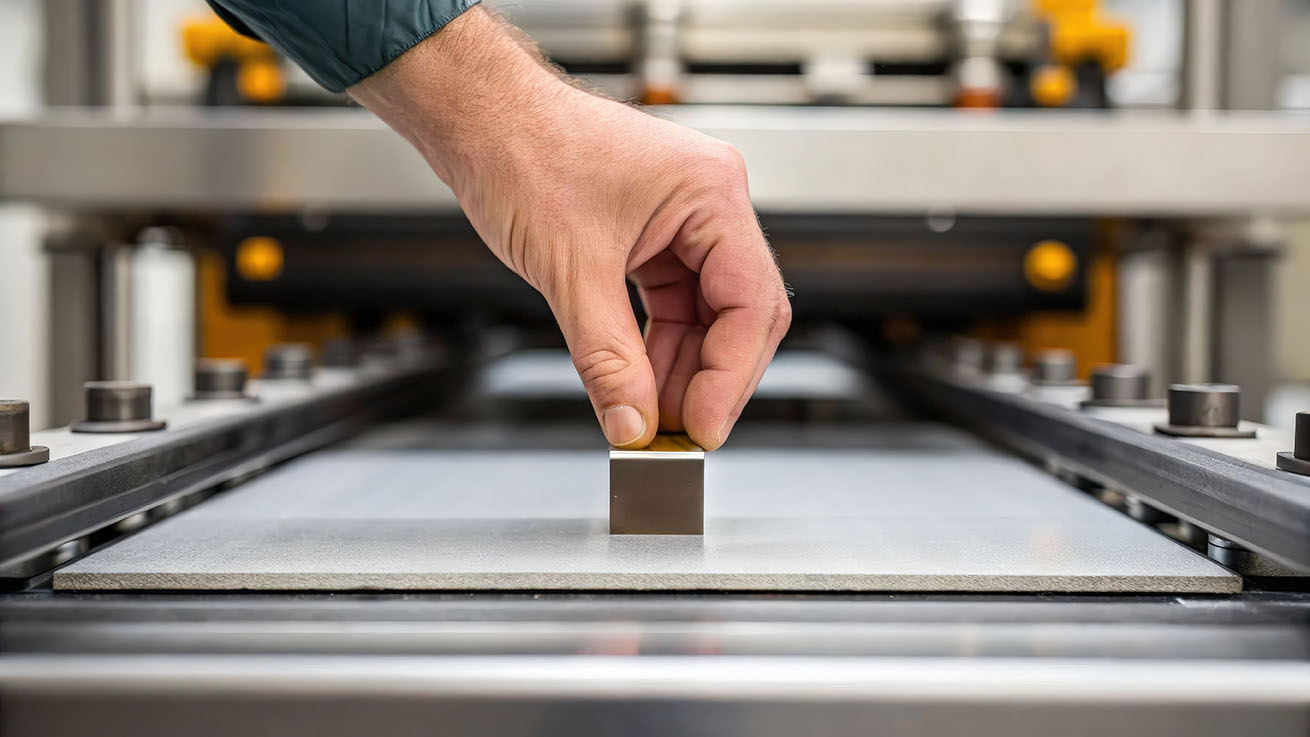

In the world of medical device safety testing, ISO 10993-5 plays a crucial role. A key aspect of this, which is sometimes overlooked in certain studies, is the T0 time point, or time zero.