Analytical Approaches for Food & Beverage Webinar

In this webinar we introduce the analytical approaches for solving food and beverage challenges including contamination.

Home » Plasma FIB – A better alternative to traditional FIB?

Innovation of new technologies and products stems from the advancement of materials. These materials may react and interact differently with each other, or they can be affected during a process or analysis. Depending on the type of material and the data you are collecting, there are techniques that are more suited than others.

That brings us to the question – is Plasma FIB a better alternative to traditional Focused Ion Beam (FIB)? It’s all relative. What are you using it on and what are you using it for?

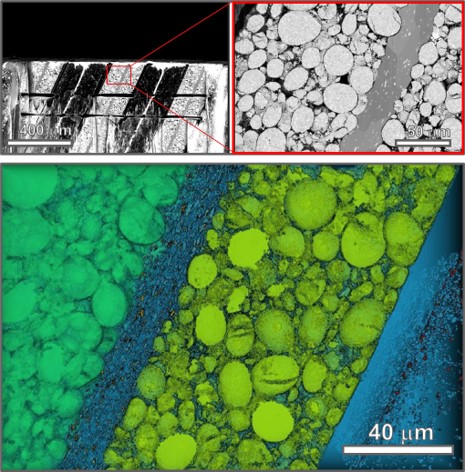

In traditional FIB, a Ga beam is used to remove material from samples to expose desired features for analysis by Scanning Electron Microscopy (SEM) or Transmission Electron Microscopy (TEM). PFIB differs from traditional FIB in that it uses various gases such as Xe, Ar, oxygen or nitrogen to generate a plasma that is used to remove material from a sample.

With Ga FIB, atoms are removed from the desired location; however, there is a limitation in the size of cut that can be prepared, limiting applications requiring a larger area to be exposed.

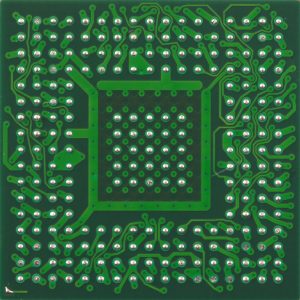

With Plasma FIB, larger cuts can be prepared more efficiently, giving us the ability to survey more material to find the root cause of a failure and reducing the time needed for an analysis. For example, the larger size capability allows the cross sectioning of entire ball bonds and laser diodes.

One of the other main advantages is that PFIB is Ga-free. Since Ga is often part of III-V materials that are important in many technologies, this is a big plus for the analysis of advanced optoelectronics samples and other materials, allowing subsequent analysis using Cathodoluminescence (SEM-CL) and Electron Beam Induced Current (EBIC) to be more accurate with less influence from sample preparation.

For some types of samples such as aluminum metal and alloys, the potential for defects induced by sample prep is also decreased with PFIB.

In summary, PFIB is a great choice for performing mm scale targeted cross-sections on a wide variety of materials such as metals, polymers, ceramics, semiconductors and composites. At Eurofins EAG we also offer Cryo FIB, in addition to an extensive range of complementary techniques that can improve the quality and usefulness of your results.

Contact us today to learn how we can help.

In this webinar we introduce the analytical approaches for solving food and beverage challenges including contamination.

Besides images provided by SEM and TEM, different attachments can be added to reveal crystalline information, including (SEM-EBSD) and TEM (TEM-PED).

Surface cleanliness is critical in how a material or a layer on a product interacts with other surfaces, which in turn can affect its functionality.

In this webinar we introduce Leachables stability studies and will cover impurities, method and stability requirements.

To enable certain features and improve your experience with us, this site stores cookies on your computer. Please click Continue to provide your authorization and permanently remove this message.

To find out more, please see our privacy policy.