Product Reliability Testing Webinar

Wednesday, March 26, 2025

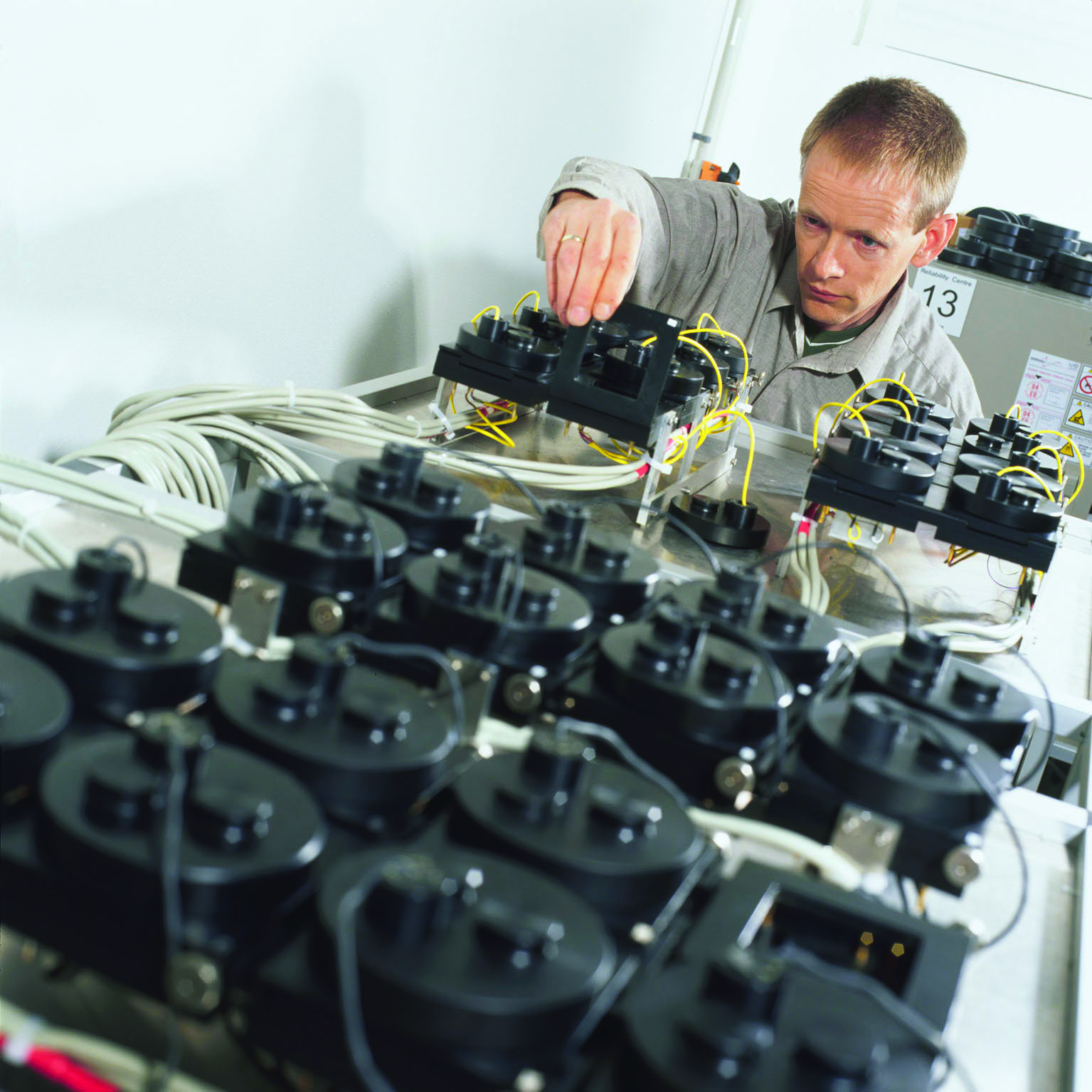

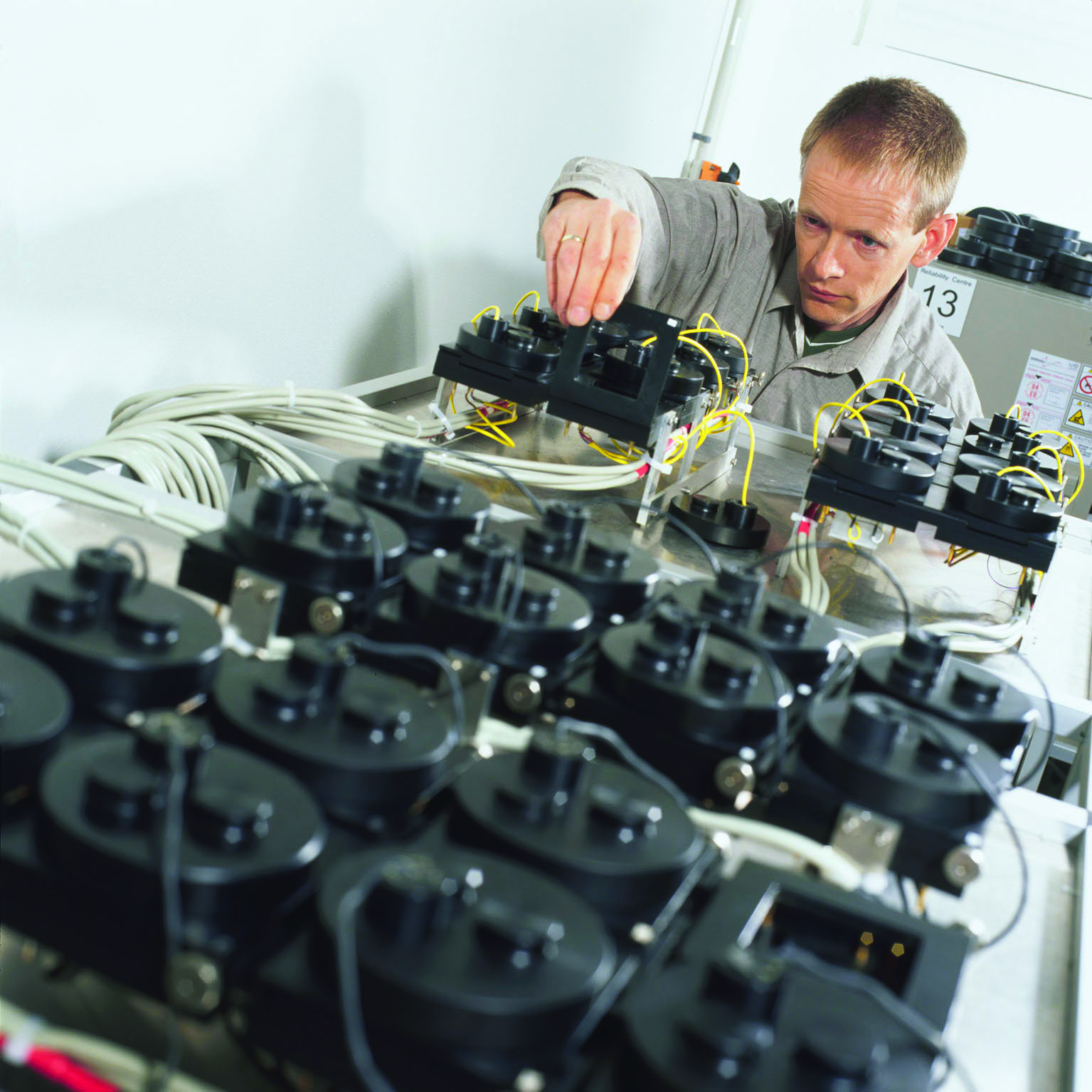

In this webinar, we will show you how Eurofins EAG supports you in the various phases of reliability testing to come to a robust product, including the different types of actual testing.

Home » Lithium ion Batteries: Opportunities and Challenges

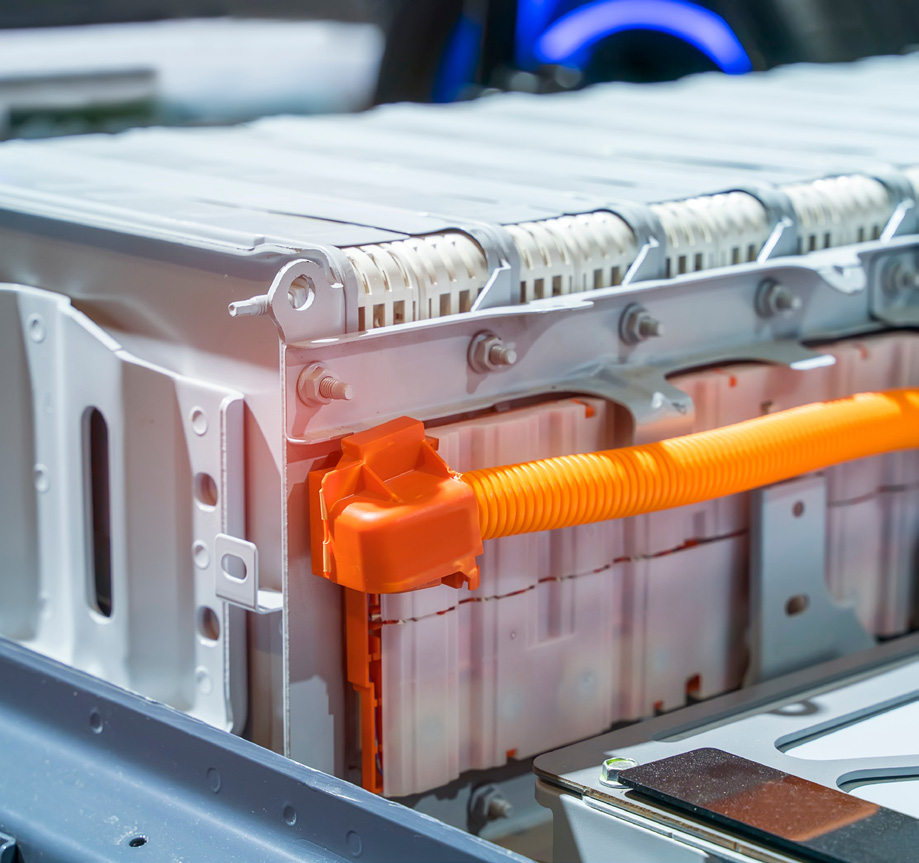

The growth and popularity of electric vehicles (EV) is putting a spotlight on Lithium-ion batteries. According to Bloomberg 2019 Electric Vehicle Outlook, EVs, including commercial and passenger, will dominate the demand of the Lithium-ion battery market in the next ten years. Lithium-ion batteries provide lightweight, efficient power for EVs and consumer electronics. Compared to nickel-metal hydride (NiMH) batteries, lithium-ion batteries have a 50 percent greater capacity in watt-hours per kilogram (w-h/kg).

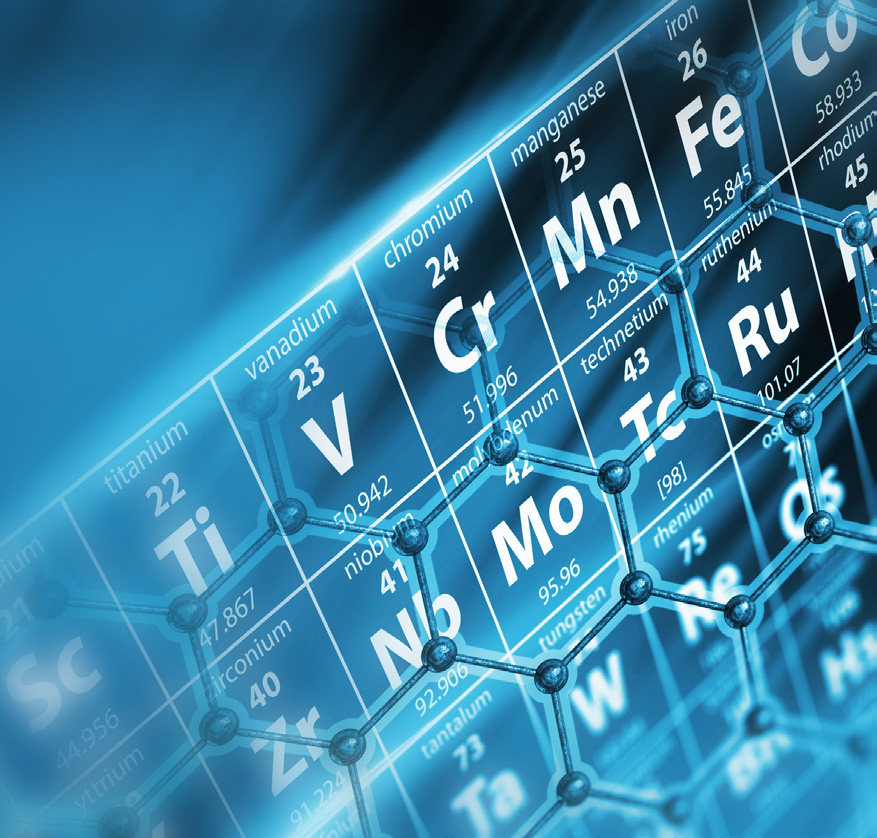

A challenge with this growing market is the limited access to mineral resources key for manufacturing lithium-ion batteries. The key minerals making up the cathode material, including Lithium (Li), Manganese (Mn), Nickel (Ni), and Cobalt (Co), is in short supply. The situation is exacerbated due to the environmental impact in mining and refining these minerals, and the need to dispose the battery waste stockpile. Thus, developing recycling capabilities of used lithium-ion batteries becomes more critical.

The market has responded to these needs, and many are capturing the opportunities. More and more recycling companies are popping up around North America. Late last year, a Canadian firm began constructing a US $175 million plant in Rochester, N.Y. When completed, it will be the largest lithium-ion battery-recycling plant in North America. The plant will have an eventual capacity of 25 metric kilotons of input material, recovering 95 percent or more of the cobalt, nickel, lithium, and other valuable elements.1

EAG scientists are leaders in lithium-ion battery recycling arena. We have developed the knowhow to measure accurately and reliably with long-term consistency. EAG scientists combine the representative sampling and validated elemental analysis techniques for accurate determination of Li/Transition Metal ratios (stoichiometry, off-stoichiometry), dopant concentration, and high sensitivity quantitation of key trace impurities.

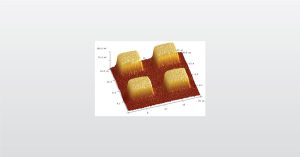

These analysis techniques include NIST High Performance Inductively Coupled Plasma Optical Emission Spectroscopy (HP ICP-OES), Inductively Coupled Plasma Mass Spectrometry (ICP-MS) and Glow Discharge Mass Spectrometry (GDMS). These are key for manufacturing Lithium-ion batteries with consistent quality, high performance, and long cycle life. EAG scientists also developed the knowhow for representative sampling and quantitative determination of transition metal contents in recycled e-waste, and purity certification of recycled Copper (Cu) foil, Aluminum (Al) foil and graphite materials. The EAG team utilizes multiple techniques such as Scanning Electron Microscopy (SEM)/Energy Dispersive X-ray Spectroscopy (EDS) and Electron Energy Loss Spectroscopy (EELS) to characterize different impurities found within a lithium-ion battery.

EAG is a valuable resource and partner in understanding the impurities found within recycled lithium-ion battery materials. At EAG we have a deeper understanding of how the impurities release from the materials and have a stellar sampling method. The battery industry is about how accurately you measure the field stock materials – it’s about production control. No one understands this better than the scientists at EAG. We would love to work with you to discover your challenges related to recycling lithium-ion batteries. Please contact us today to learn how we can help.

1Kumagai, J. (2021, January 5). Lithium-Ion Battery Recycling Finally Takes Off in North America. Retrieved from spectrum.ieee.org/: https://spectrum.ieee.org/lithiumion-battery-recycling-finally-takes-off-in-north-america-and-europe

Wednesday, March 26, 2025

In this webinar, we will show you how Eurofins EAG supports you in the various phases of reliability testing to come to a robust product, including the different types of actual testing.

In this webinar will be presenting information on scanning Microwave Impedance Microscopy (sMIM) operation.

Surface cleanliness is critical in how a material or a layer on a product interacts with other surfaces, which in turn can affect its functionality.

In sectors like the automotive industry, ATE plays a pivotal role in verifying the proper and reliable operation of critical systems.

To enable certain features and improve your experience with us, this site stores cookies on your computer. Please click Continue to provide your authorization and permanently remove this message.

To find out more, please see our privacy policy.