Automated Test Equipment (ATE) Can Assist in the Automotive Industry

In sectors like the automotive industry, ATE plays a pivotal role in verifying the proper and reliable operation of critical systems.

Home » Is my surface clean? Effects of Surface Cleanliness

Imagine frying an egg in a pan that’s several years old. You can’t get the egg to stay in one piece because it’s now stuck, and you need to scratch it off the surface of the pan with your spatula. The pan has build-up from the hundreds of times you’ve used it and you’ve never been able to get it back to its new and clean condition. The coating has degraded, it’s no longer a non-stick pan and it’s not functioning as it should. This is just an everyday, simplified example of how cleanliness can affect a product’s performance.

Surface cleanliness is critical in how a material or a layer on a product interacts with other surfaces, which in turn can affect its functionality. These products can be from various industries, from traditional cookware to high tech electronics, to medical devices and many more.

In the electronics industry, components are made up of multiple layers. When building layer upon layer, interface contamination can affect adhesion and deposition of subsequent layers. Correct preparation of the surface is needed to ensure the success in the following step.

In the semiconductor manufacturing process, sufficient rinses need to be done to remove photoresist residue and other chemicals in post clean-up. Care may also need to be taken during any extended sample storage while waiting for the next step in the process, to prevent chemicals from condensing onto the sample. Lack of preparation and contamination prevention will ultimately affect the lifetime or long-term reliability of the end product.

In the medical device industry, surface cleanliness is of utmost importance when manufacturing a product. The coating and surface of an implantable device must be tested to ensure conformance to regulations within the industry. In addition, surface contamination can cause added concern and can increase the probability of your body rejecting the implant.

So how clean is clean? Sometimes contamination is clearly visible. You can see particles, thick films or residue that shouldn’t be present on the surface; but what if you can’t see anything on the surface? You might think your surface is clean, but the product is not functioning as it should. Eurofins EAG Laboratories can help in either scenario. We have a wide range of analytical techniques to help you identify such contamination.

For visible contamination, the size and shape of the particle, droplet or residue size can help determine which techniques to use. Commonly used techniques include Fourier Transform Infrared Spectroscopy (FTIR), Raman Spectrometry and Scanning Electron Microscopy (SEM) to either confirm the size and shape and/or to identify contaminants and their molecular components, while X-Ray Fluorescence (XRF) and Energy Dispersive X-ray Spectroscopy (EDS) can be used for elemental composition. For contamination in the form of a liquid, FTIR and Gas Chromatography – Mass Spectrometry (GC-MS) can identify trace impurities in liquids, droplets or solvents.

What can we do when the contamination is not clearly visible? At Eurofins EAG, our broad range of tools offers our clients a variety of techniques to help in this investigation. The surface sensitivity of Time-of-Flight Secondary Ion Mass Spectrometry (TOF-SIMS) makes it a good first pass at problem solving to give an overview of what types of species are present on a sample. A good control sample would be beneficial in the research process as it would provide a comparison. If the specific location of the contaminant is unknown, X-ray Photoelectron Spectroscopy (XPS) can be used to compare the two samples. For buried surface contamination, a combination of Auger Electron Spectroscopy (AES), Focused Ion Beam (FIB) and Secondary Ion Mass Spectrometry (SIMS) can be used to explore deeper into the material and search for contaminants between layers. We also have Liquid Chromatography – Mass Spectrometry (LC-MS) to measure extractables and leachables from the surface.

With their many years of experience at Eurofins EAG, our technical experts have been exposed to a huge variety of contamination problems in many different industries. With our breadth of techniques and expertise, we work with our clients to help identify and solve problems based on industry standards or regulations, customer requirements or preference, or we can design highly customized tests just for you.

Contact us today to learn how we can help and keep an eye out for our upcoming blog on surface roughness.

In sectors like the automotive industry, ATE plays a pivotal role in verifying the proper and reliable operation of critical systems.

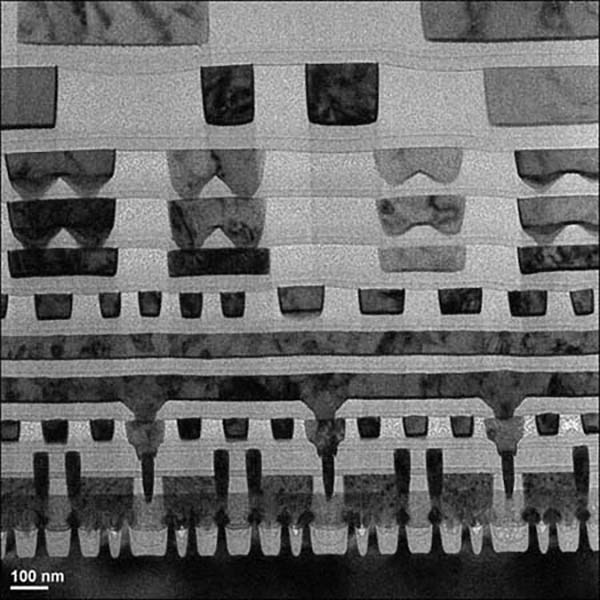

Image processing can be used to generate high density critical dimension measurements that allow us to extract the full profile of the interfacial roughness in a multilayer stack.

EAG Scientists utilize GDMS analysis to perform Elemental Depth Profiling for chemical purity evaluations for aerospace & defense.

In this webinar we introduce FIB Circuit Edit which allows the cutting of connections and placement of new lines in a semiconductor die

To enable certain features and improve your experience with us, this site stores cookies on your computer. Please click Continue to provide your authorization and permanently remove this message.

To find out more, please see our privacy policy.