TOF-SIMS Webinar

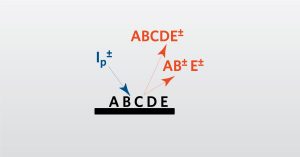

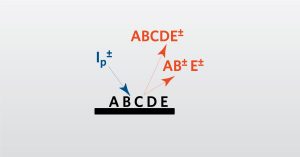

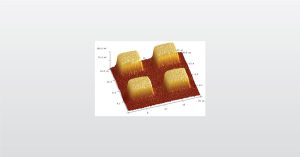

In this webinar we introduce TOF-SIMS which is a surface analysis technique used to investigate the extreme surfaces of samples.

Home » Extraction Expertise for Medical Device Chemical Characterization

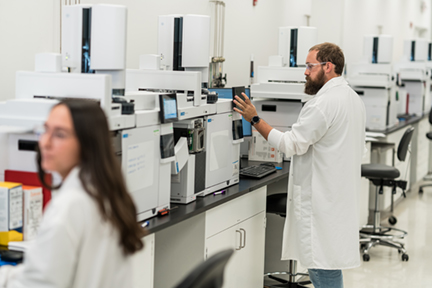

Extractable studies are performed on medical devices to evaluate potential chemical release from a medical device during clinical use.

The primary guidance for medical device extractable studies is ISO 10993-18 “Chemical characterization of medical device materials within a risk management process”. In this international standard, a number of extraction study approaches are laid out, which are applied to medical devices based on the intended device use.

EAG offers advanced expertise and a risk-based approach for medical device extractable study design and execution, including the latest FDA expectations.

ISO 10993-18 provides guidance for the type of extraction study necessary for chemical characterization, based on device contact.

In this webinar we introduce TOF-SIMS which is a surface analysis technique used to investigate the extreme surfaces of samples.

In this webinar will be presenting information on scanning Microwave Impedance Microscopy (sMIM) operation.

Join us for an engaging in-person event at our St. Louis MO Lab to discover the exciting opportunities at EAG Laboratories.

As a trusted partner in the consumer electronics industry, we are ready to meet the evolving industry needs, advancing innovation and excellence.

To enable certain features and improve your experience with us, this site stores cookies on your computer. Please click Continue to provide your authorization and permanently remove this message.

To find out more, please see our privacy policy.