Analytical Investigations of Plastics & Polymers Webinar

In this webinar we introduce Analytical Investigations of Plastics and Polymers to tackle failure issues quickly and effectively

Home » Evaluating the Cleanliness of Medical Devices

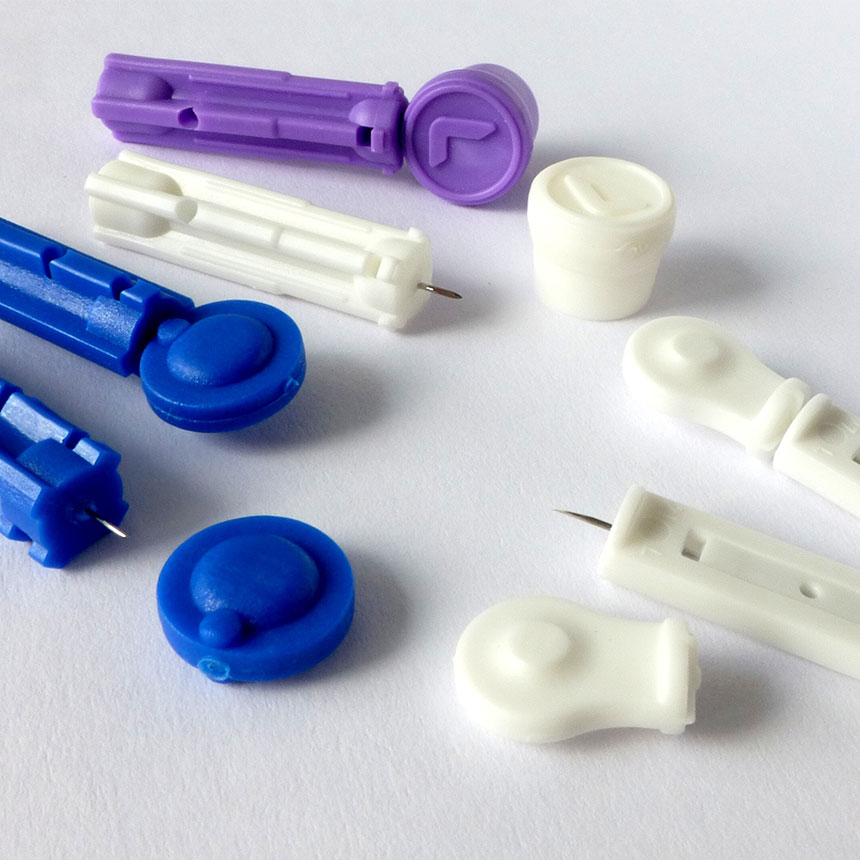

How clean is clean? In the medical device industry, there are specific requirements that must be met to pass certain quality standards. For medical devices such as surgical blades, glucose sensor needles, sutures, and surgical tools, a cleaning procedure is typically included in the manufacturing process to qualify the cleanliness of these products before they are released to market. As part of a medical device manufacturer’s internal quality control process, an evaluation of the level of cleanliness is needed to verify how effective their cleaning procedure is. This type of testing may be done regularly throughout the year for monitoring and quality assurance.

In addition to regularly monitoring the quality and effectiveness of a cleaning procedure, there are other scenarios that may require the evaluation of product cleanliness. When a manufacturer makes changes to their cleaning procedure, they may need to compare or evaluate the results to verify that the new procedure is on par with the previous process. When a manufacturer buys certain parts used in their product from different suppliers, the manufacturer may want to compare the cleanliness of the same parts from different suppliers to determine which supplier to choose. When there are multiple manufacturing sites, verification may be needed to confirm that cleaning procedures are consistent and equally effective between sites. Cleanliness evaluation may also be needed to help determine which process is more optimized, less costly and more effective.

Eurofins EAG has a wide array of analytical techniques to verify the cleanliness of medical devices. We’ve helped our customers evaluate the cleanliness of their products using techniques including Non-volatile Residue (NVR) analysis, often in combination with Fourier Transform Infrared Spectroscopy (FTIR), X-ray Photoelectron Spectroscopy (XPS) and Time-of-Flight Secondary Ion Mass Spectrometry

(TOF-SIMS). NVR is a quantitative technique used to measure the amount of residue present, typically down to ppm levels. To investigate further, FTIR is a qualitative technique that can determine the composition of the residue. XPS and TOF-SIMS can be used to study the actual surface of a medical device, focusing on specific areas.

At Eurofins EAG, we have specialized tools to verify material identification and composition. Our technical experts have many years of experience working with an extensive range of materials. Contact us today to learn how we can help you with your next project.

In this webinar we introduce Analytical Investigations of Plastics and Polymers to tackle failure issues quickly and effectively

Lithium-ion batteries provide high energy density mobile power but come with three challenges: performance, safety and battery life.

In this webinar we introduce X-ray Fluorescence Spectroscopy (XRF) which is a analytical technique used for elemental analysis of materials.

Vertical-cavity surface-emitting lasers, or VCSELs, play a major role in the consumer electronics 3D sensing industry.

To enable certain features and improve your experience with us, this site stores cookies on your computer. Please click Continue to provide your authorization and permanently remove this message.

To find out more, please see our privacy policy.