SEM-CL Webinar

In this webinar we will focus on SEM Cathodoluminescence (SEM-CL) Analyses for Materials such as compound semiconductors

Home » Elemental Composition using XRF

What is this thing made out of? From product development to failure analysis, this is a common question. When creating something new, it’s best to acquire as much information as you can about the materials you are working with. The more details you have, the better you can understand how these materials can potentially react with other substances, processes and environments. Verification of supplier materials is also very important in early stages of product development, and possibly during mature manufacturing as well. For failure analysis, characterization of your material is also key to help determine the root cause of a failure.

What is one of the first steps in material research and investigation? It’s materials identification and elemental composition determination. X-ray Fluorescence (XRF) is a great technique for this type of materials analysis. It is considered both a bulk technique and trace elemental technique all in one.

XRF is a non-destructive technique that is used to quantify the elemental composition of materials. From liquids, loose powders and organic molecules to plastics, glasses and alloys, XRF can accurately determine the elements present.

The technique can measure the composition of bulk materials as well as the thickness and composition of thin films. XRF covers nearly the entire periodic table from boron though uranium.

Under normal operating conditions, XRF can be used to determine the composition of an unknown substance. As we gather additional information about a sample, the accuracy of that elemental composition can be improved via the use of reference standards. This powerful technique is very sensitive and can measure down to the ppm level. Even without standards, the relative accuracy is typically in the 5-10% range for major and minor elements and can be improved significantly when standards are available.

At Eurofins EAG, we offer XRF services using three different types of tools: handheld-XRF, WD-XRF (wavelength dispersive) and ED-XRF (energy dispersive). Handheld-XRF is very useful for larger samples and for on-site inspections of materials. There is no sample preparation needed and it is a useful tool for basic material identification to screen for the presence or absence of particular elements. For WD-XRF and ED-XRF, the main difference is the way in which the X-rays are separated and measured. WD-XRF has very good energy resolution, which leads to fewer spectral overlaps and improved background intensities. ED-XRF has higher signal throughput, which enables small area analysis or mapping. Each method has its place, depending on the analytical goal and samples under investigation.

With our many years of providing XRF services, our scientists have the experience and knowledge working with a wide range of samples and industries. We have implemented various sample prep techniques to enhance our understanding of your samples. Combined with our other techniques, we have the ability to tailor our analyses to meet your needs.

Contact us today to learn how we can help you on your next project.

In this webinar we will focus on SEM Cathodoluminescence (SEM-CL) Analyses for Materials such as compound semiconductors

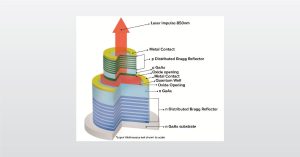

In the full webinar we will introduce analyzing VCSELs with a focus on secondary ion mass spectrometry (SIMS)

In this webinar we introduce evaluating wearable safety including product recall, lawsuits, and regulatory agency inquiries.

Join us for an engaging in-person event at our Sunnyvale CA lab.

To enable certain features and improve your experience with us, this site stores cookies on your computer. Please click Continue to provide your authorization and permanently remove this message.

To find out more, please see our privacy policy.