Failure Analysis in Aerospace Advancement

In the aerospace industry, electronics are subjected to extreme environmental variables. EAG’s failure analysis group can help solve potential problems that may arise.

Home » Effects of Surface Roughness

It’s just you and the road. You’re driving down a newly paved highway, as smooth as if you’re gliding on air. A mile down, the road conditions change and suddenly, you’re dodging potholes and hitting rough patches. Good thing your suspension is absorbing the bumps, helping to keep your coffee from spilling over! Miles later you’re back on a smooth surface. Rain begins to pour and you realize the pavement is too smooth which is causing you to slip and slide. The road isn’t absorbing the water, instead puddles are beginning to form due to poor drainage. You’re now wishing you had purchased those new tires you had kindly declined at your last service. No traction and a slippery road are now becoming a dangerous nightmare.

The roughness of a surface and how it interacts with surrounding materials and elements can affect something as simple as driving down the road but can also have a significant impact on material technology and its functionality.

Do I need a rough or smooth surface? Well, that depends on the material or the final end-product. The vast majority of products nowadays are designed using multiple layers.

As you build successive layers, roughness can multiply. Height variations can then occur which can affect subsequent processes. Adding layers to non-flat surfaces can potentially lead to delamination and crack formation for certain product types. However, there are also scenarios whereby a defined roughness is needed to help with adhesion.

For the optics industry, using mirrors, windows, and lenses, the smoothness of the surface can affect the transmission of light so any surface roughness will affect the functionality of the product. Some applications need carefully patterned surfaces with complicated properties for different light interference, diffraction, and reflectance. This could result in a combination of a smooth surface with a rough layer on top of that.

In the medical device industry, a rough surface on an implant can cause subsequent build-up of scar tissue. Nitinol stents need to be polished sufficiently to reduce the likelihood of this happening. Contact lenses should be smooth for comfort and clarity. However, bone grafting needs a controlled rough surface with a larger surface area for stronger bonding. Some medical devices are manufactured using two polymers adhered together whereby the interface roughness is deliberate controlled, to keep them intact.

For semiconductors and aerospace, surface preparation is key for subsequent process steps. Sometimes a certain roughness is needed without changing the chemistry of the layer; or depositing a thicker layer of metal requires a stronger adhesion to a subsequent layer.

Whether you need a smooth surface or a specific roughness to your material, Eurofins EAG can help characterize the material each step of the way. Using our analytical techniques, we provide our customers with statistics and parameters giving them an impartial view of the surface. These numbers are derived from images which offer a visual representation of surface topography.

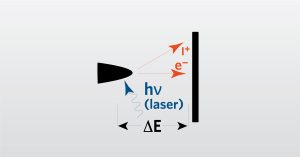

Sometimes a preliminary investigation is needed and Scanning Electron Microscopy (SEM) can be used to identify regions of interest. Stylus Profilometry provides a simple roughness measurement as a single line scan across the sample. Optical Profilometry (OP) offers larger scale areal measurements and, through image stitching, can provide topographies of up to a centimeter. If you need to get down to the angstrom level with high resolution, Atomic Force Microscopy (AFM) is the way to go. AFM can analyze areas of less than 1 – 100 micrometers.

At Eurofins EAG, our technical experts have many years of experience working with a wide range of materials, from soft to hard surfaces. With our breadth of techniques and expertise, we work closely with our clients to tailor the analytical plan to their needs.

Contact us today to learn how we can help.

In the aerospace industry, electronics are subjected to extreme environmental variables. EAG’s failure analysis group can help solve potential problems that may arise.

Silicon carbide is increasingly considered a potential replacement for traditional silicon semiconductors due to its superior properties.

In this webinar we introduce Atom Probe Tomography (APT) which is a technique that provides three-dimensional (3D) chemical and spatial maps.

Blisters were observed in paint applied to steel plates that had undergone treatment with a corrosion inhibitor. An investigation was performed to determine if there was evidence of contamination on the inside of the blister.

To enable certain features and improve your experience with us, this site stores cookies on your computer. Please click Continue to provide your authorization and permanently remove this message.

To find out more, please see our privacy policy.