Failure Analysis of Reliability Webinar

In this webinar we introduce The Failure Analysis of Reliability Testing Samples as applied electronic and semiconductor devices

Home » Complementary Techniques: X-Ray & SAM

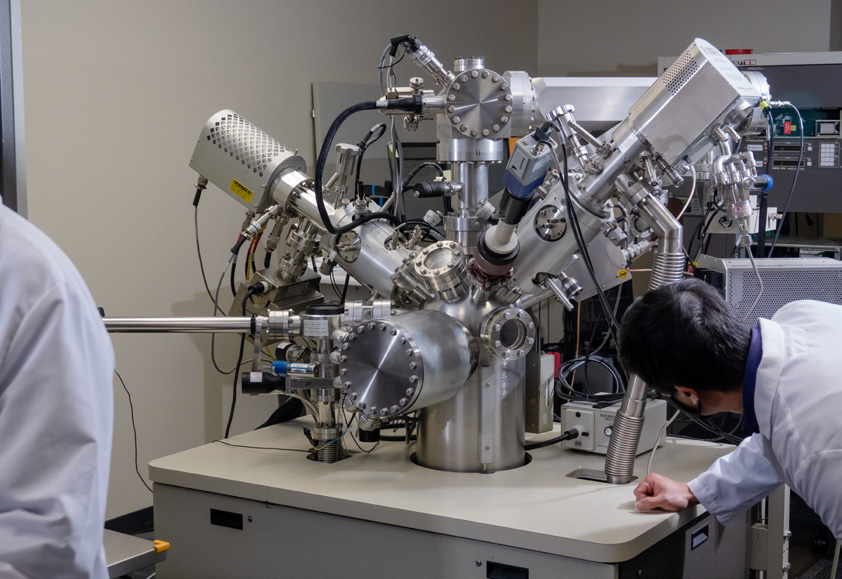

X-ray imaging is a great non-destructive technique that is used in many industries to help visualize internal construction. Scanning acoustic microscopy (SAM) is another non-destructive technique that relies on ultrasonic sound waves to characterize internal construction, similar to how sonar and pediatric ultrasounds are performed. Both techniques rely on variations in material properties to generate contrast in the resulting images. This contrast helps distinguish different materials or identify structural anomalies.

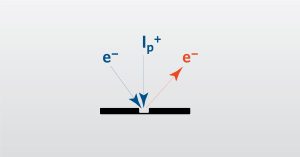

As X-rays pass through materials, a certain amount is absorbed or scattered. The remaining X-rays that penetrate the material allow us to assess the material’s X-ray attenuation. By contrasting the number of X-rays that pass through with those that do not, a 2D image or 3D reconstruction can be generated.

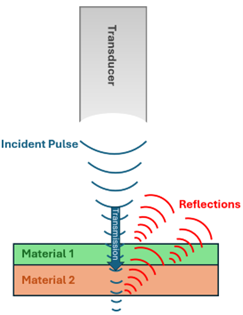

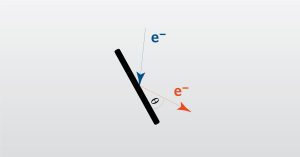

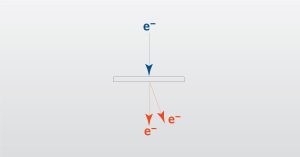

As an ultrasonic sound wave travels through a stack of materials, a certain amount of reflection and transmission occurs at each interface the pulse encounters. The acoustic impedance of the two materials determines how much of the incident pulse is reflected at the interface and how much is transmitted into the next material. Reflections at different times can reveal thickness or material variations as the pulse propagates through the package. A 2D image can be created by analyzing reflected waves within a specific time range that corresponds to a particular layer in the device.

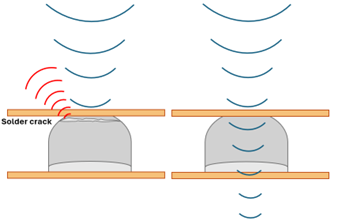

While both techniques are powerful non-destructive approaches that can help characterize internal features that aren’t optically visible, they are not interchangeable. Instead, they should be considered as complementary techniques where different information is portrayed in each image. X-ray can portray density and thickness variations that can help to characterize solder voiding. Scanning acoustic microscopy can show interfacial differences, down to submicron levels.

For example, if the solder bump was close to the expected thickness (and thus looked very good from a relative x-ray standpoint) but did not make contact with one of the pads, it would be classified as a false positive. Scanning acoustic microscopy, on the other hand, can detect submicron delamination within materials which makes it a great technique to identify open bumps, delamination and internal cracks.

Although the techniques are not interchangeable, there are situations when it is much more advantageous to use one over the other.

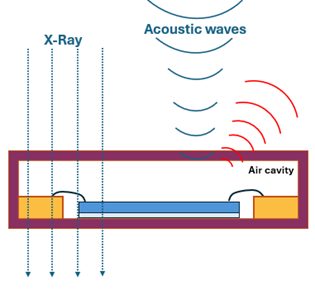

For example, in a dense area with extensive gold metallization, X-ray imaging may not provide much contrast. However, acoustic microscopy won’t be as adversely affected and thus may provide a more insightful image. Likewise, if there is an air cavity in a hermetically sealed package, sound waves would not be able to propagate past it, but X-rays would be unaffected.

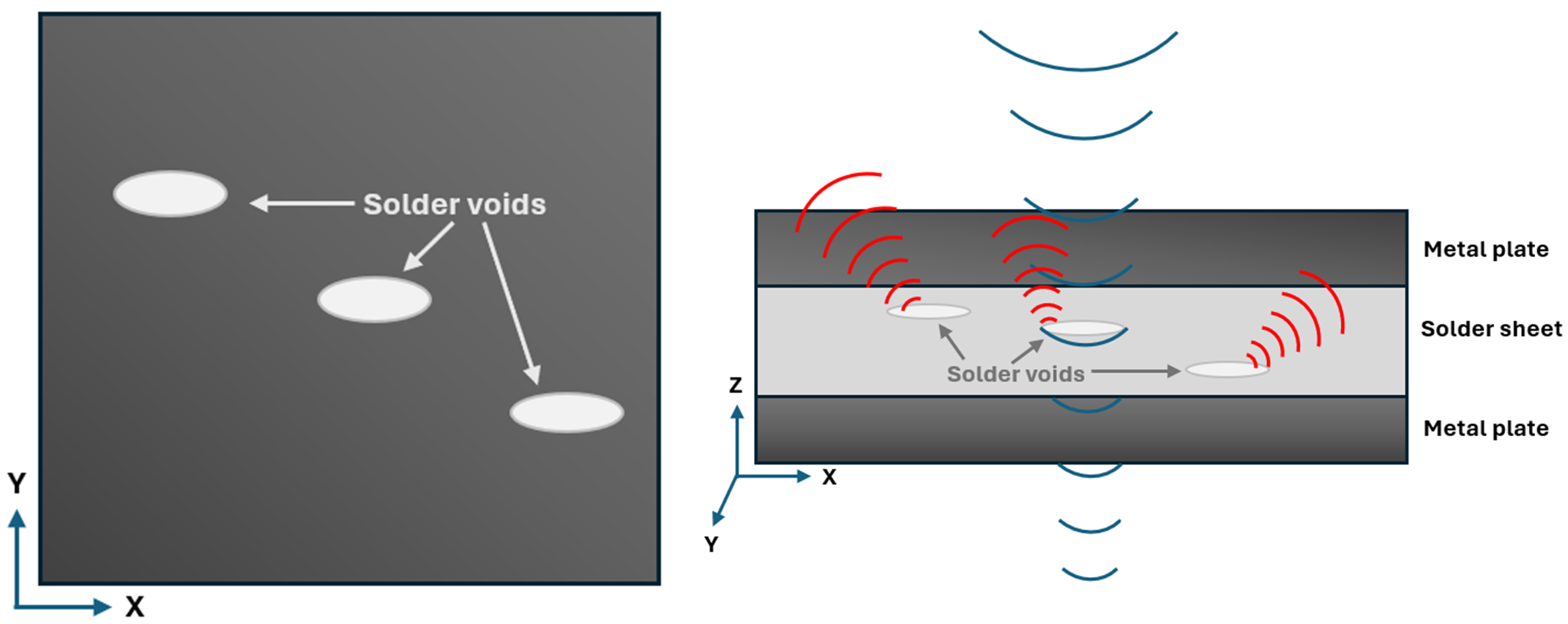

Traditionally, combining the two techniques can provide more in-depth information than performing one or the other. For example, if there is a sheet of solder sandwiched by two metal plates, X-ray imaging could capture potential voids in the x-y plane. However, identifying where the voids are in the z plane will be challenging.

Reflective scans can give an idea of where the first void is along the propagation path, depending on the orientation of the scan. Most of the incident pulse is reflected at this point and thus there is no data collected beyond the void. By comparing the total voids (as seen in X-ray) and the first voids in the path (as seen in SAM), the location of the voids in the z direction can be inferred.

Both 2D X-ray imaging and acoustic microscopy are effective non-destructive testing methods.

They are based on different physical principles, offer varying imaging depths and resolutions, and are suited to different materials and applications. While SAM provides interfacial information, X-ray imaging offers an aggregate view. Ultimately, the choice between these techniques depends on the specific requirements of the imaging task, including the desired level of detail and resolution.

In this webinar we introduce The Failure Analysis of Reliability Testing Samples as applied electronic and semiconductor devices

This webinar will focus on Electron Backscatter Diffraction (EBSD) and Electron channeling contrast imaging (ECCI)

In this webinar we will introduce the principles of Transmission Electron Microscopy (TEM) with a focus on real-world problem-solving.

November 2, 2023

Please join us for coffee and conversations! Enjoy a cup of coffee and pastries as you get to know our technical experts.

Home » Complementary Techniques: X-Ray & SAM

This section is the opening paragraph that shows how EAG relates to real life.

Text here

Text here

Text here

A client wanted to investigate the delamination of food packaging multilayer laminate. Roll stock did not meet seal strength specification.

In this webinar we introduce Advanced Focused Ion Beam (FIB) which provides precise cross-section imaging analysis

EDS and EELS can be coupled with SEM, STEM and TEM to determine the elemental composition, spatial distribution and segregation of elements.

Polymeric films used in an outdoor application experienced reduced adhesion over time. The client suspected that UV degradation was occurring.

To enable certain features and improve your experience with us, this site stores cookies on your computer. Please click Continue to provide your authorization and permanently remove this message.

To find out more, please see our privacy policy.