EDS & EELS Webinar

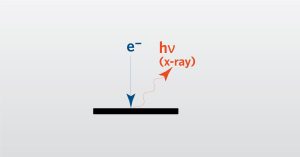

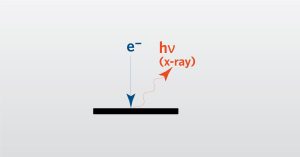

In this webinar we introduce Energy Dispersive X-ray Spectroscopy (EDS) and Electron Energy Loss Spectroscopy (EELS)

Home » A Picture is Worth a Thousand Words – TEM, STEM and AC-STEM

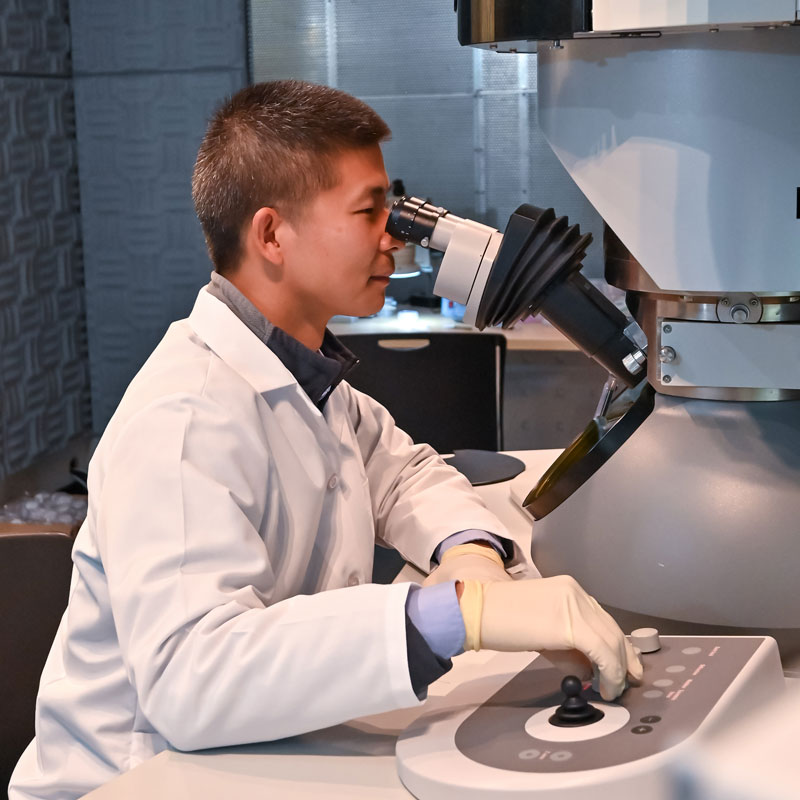

I’m sure you’ve heard of the phrase, ‘A picture is worth a thousand words.’ It implies that a picture can explain or describe something as well as or possibly even better than a cluster of words. Transmission Electron Microscopy (TEM), Scanning Transmission Electron Microscopy (STEM), and Aberration Corrected Scanning Transmission Electron Microscopy (AC-STEM) are microscopy techniques that can do just that. They are similar techniques that image a sample using an electron beam. This delivers high resolution images which provide a detailed view of a material or product such as layer thickness, critical dimensions, defects, segregation and local differences in atomic structure.

All three techniques can provide useful information, but what helps to determine the best suited technique for your sample? In general, the size of your sample can be one of the main defining factors. If we’re talking about size, we can say that TEM may be sufficient for a larger feature size and as the region of interest decreases in size, STEM and AC-STEM may be preferred.

TEM uses a broad, parallel beam which is good at surveying a sample. STEM uses a focused beam which scans the sample line by line, as described in its name.

With this process, STEM can provide more detailed chemical analysis locally with the help of EDS or EELS. As you get down to the atomic scale, AC-STEM would be your preferred choice. In STEM, aberration may cause low resolution images. Aberration Corrected STEM ‘corrects’ the aberration to achieve atomic resolution. The size of the beam is much smaller than the beams used for TEM and non-aberration-corrected STEM which helps to distinguish atoms more clearly.

As mentioned earlier, sample feature size may be one of the defining factors for technique choice; however, there are other factors that can come into play. The type of material or ultimately the features that the client is most interested in learning about can determine the technique to use.

For example, the quantum wells in LEDs can be extremely thin where we would need AC-STEM to see irregularities between quantum well – barrier interfaces. This is beneficial for compound semiconductors. Even for the thicker layers in compound semiconductors, you can obtain images with atomic number related contrast which can be more clearly seen observed using STEM. For failure analysis related jobs, we may go straight to STEM to pinpoint a failure. There are so many factors to keep in mind. What if you still don’t know which technique to use? That’s where we come in!

At Eurofins EAG, we are your trusted partner in advanced microscopy analysis. We are one of the few commercial labs to offer AC-STEM services along with a vast array of complementary analytical techniques. With our years of experience working with a multitude of materials and industries, we can help determine the best suited techniques for your project.

Contact us today to learn how we can help you on your next project.

In this webinar we introduce Energy Dispersive X-ray Spectroscopy (EDS) and Electron Energy Loss Spectroscopy (EELS)

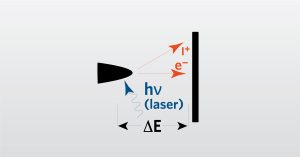

In this webinar we introduce Atom Probe Tomography (APT) which is a technique that provides three-dimensional (3D) chemical and spatial maps.

Failure analysis plays a crucial role in the development and maintenance of medical device electronics.

In vitro biocompatibility testing is a powerful tool in the risk assessment of wearable devices. View our webinar to learn more!

To enable certain features and improve your experience with us, this site stores cookies on your computer. Please click Continue to provide your authorization and permanently remove this message.

To find out more, please see our privacy policy.