Thermal Imaging Solutions for Microelectronics and Optoelectronics

Home » Thermal Imaging Solutions for Microelectronics and Optoelectronics

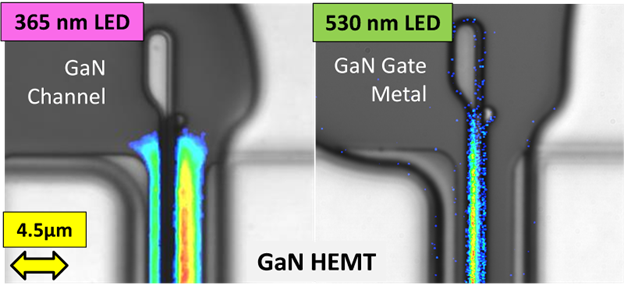

Eurofins EAG Laboratories has recently enhanced its thermal imaging capabilities with the integration of Microsanj equipment, using thermoreflectance and material index of refraction principles to achieve unparalleled spatial and temporal resolution.

The development and adoption of Thermoreflectance (TR) Thermal Imaging was pioneered by Microsanj to address the evolving technologies that utilize new materials with shrinking geometries. These devices have increased construction complexity and high-power densities that require peak electro-thermal performance and reliability. Industries supported include semiconductors, power electronics, AI, automotive, 5G/6G telecom, photonics, aerospace/military, medical devices, robotics, and cloud computing.

Case Study Example: Transient Thermal Imaging of a Logic Integrated Circuit

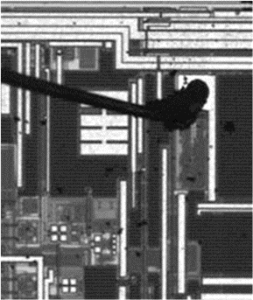

The following example illustrates the transient analysis capability using a high-speed logic IC as the device under test (DUT). The unencapsulated chip measures 1.6 mm by 1.1 mm and is 500 mm thick. The chip is wire-bonded for top-side thermal imaging, and its optical image is shown in Figure 2.

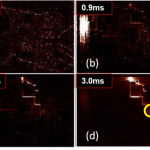

Figure 3 displays the thermal intensity map at four different time intervals from 0.5 ms to 3.0 ms after powering on the chip. In Figure 3a, the left side of the chip heats almost immediately after the applied bias, peaking around 0.9 ms as seen in Figure 3b. By 0.95 ms, shown in Figure 3c, another region in the upper central part of the chip begins dissipating power. At 3.0 ms, shown in Figure 3d, the left side of the chip has cooled down, and a new hotspot is observed in the right central portion of the chip.

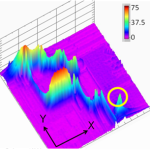

According to the circuit design, the initial heat-up on the left side of the device is expected. However, the heating observed at 3 ms was unexpected and related to a latch-up failure. This failure is marked by the circle on the 3D temperature plot shown in Figure 4.

These time-dependent thermal events would have gone undetected without transient thermal analysis. Once identified, it is up to the circuit designer to interpret their significance; some events may be harmless to device performance or reliability, while others could lead to catastrophic failure.

Analyzing and understanding the time-dependent thermal behavior of modern high-speed logic integrated circuits is crucial for ensuring optimal performance and long operating life. Combining submicron spatial resolution thermoreflectance thermal imaging with high-speed transient capability offers circuit designers the necessary information to balance device performance and reliability. This capability also gives manufacturing and quality assurance teams a non-invasive tool to monitor processes and identify potential early device failures.

Would you like to learn more about thermal imaging solutions for microelectronics and optoelectronics?

Please complete the form below to have an EAG expert contact you.