Statistical Analysis of 3D Particles Using FIB SEM Tomography and Image Processing

Home » Statistical Analysis of Three-Dimensional Particles Using FIB-SEM Tomography and Image Processing

FIB-SEM tomography and image processing enable us to extract statistical analysis of particles from three-dimensional and high-resolution imaging data.

Particle characteristics such as size distribution and shape are an important quality criterion in many fields. These characteristics significantly affect material flowability, reactivity, solubility and so on. Imaging is a good technique to acquire data on a sample consisting of particles with a range of sizes and shapes, since it can provide both the general and the local information. Focused ion beam scanning electron microscopy (FIB-SEM) is a powerful tool that can be used to collect tomography information about a sample. The SEM can capture high-resolution images of features ranging from hundreds of microns to nanometers in size. When paired with FIB, the SEM is also able to collect images from the sample’s interior. This is done by using the FIB to mill away small volumes of material to reveal a local cross-section. By this method, nm-to-micron thick slices of material can be serially milled away to create a stack of SEM images. This stack of two-dimensional (2D) images can then be used to construct a three-dimensional (3D) dataset. Once the 3D volume is generated, image processing methods can be applied to further gather the particle statistical information.

In this application note, we demonstrate our capability to quantitatively analyze particle morphology with the conventional image processing methods. Download the application note to learn more.

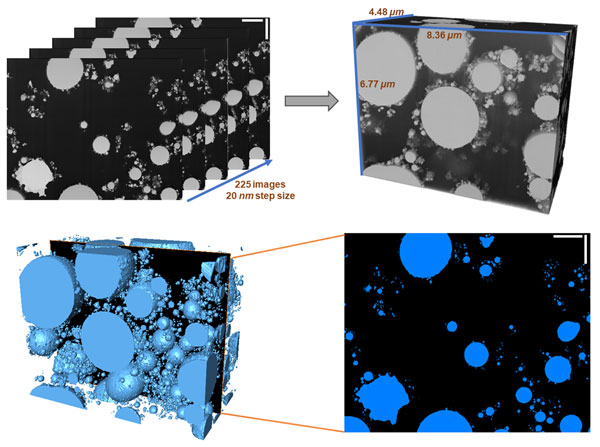

Top image – 3D structure created by stacking FIB-SEM images together. Scale bar size: 1000 nm.

Bottom image – Particles extracted as a whole section by a threshold step. The particle section is shown in blue. Scale bar size: 1000 nm.

Would you like to learn more about FIB SEM?

Contact us today for your needs. Please complete the form below to have an EAG expert contact you.