Multilayer Packaging Film Characterization

Home » Multilayer Packaging Film Characterization

INTRODUCTION

Flexible packaging films function as barriers to extend shelf life of food products by protecting them from the environment. These films can be single layer or multi-layer constructions. Polyolefins (polypropylene and polyethylene) account for the majority of the packaging film market (~65% in 2009). Multi-layer film processing methods include monolayer or coextruded film extrusion (blown or cast), coextrusion blow-molding, profile coextrusion, thermal lamination, and coating. Packaging applications include sleeves, pouches, bags, and shrink films. Each layer imparts specific properties: heat sealability, gas barrier, printability, toughness, puncture resistance, moisture resistance, etc.

Understanding the construction/composition of films is beneficial for a variety of reasons:

- Reverse engineering to identify an alternative source

- Patent infringement litigation support

- Failure analysis to determine root cause (e.g., delamination, ink bleed, processing defects)

LAYER CONSTRUCTION

Layer construction can be investigated using cross-sectional analysis. Cross-sections can be prepared in several ways, including razor blade cut, microtome, cryo-microtome, ion milling, cryo-ion milling, focused-ion beam (FIB), and plasma FIB, depending on film thickness and if relatively soft/tacky adhesive tie layers are present. With the latter, cryogenic processes are necessary to prevent smearing, tearing, plastic deformation and pullout. Cross-sections can also be prepared at different angles to artificially increase layer thickness.

Depending on the film manufacturing process, optical microscopy (OM) and/or scanning electron microscopy (SEM) can be used to determine the number/thickness of layers in cross-section. Typically, films that are laminated or coated have more well-defined layer interfaces that scatter light and can be readily observed by OM.

Often SEM is used to visualize and distinguish layers when the following situations apply:

- Layers have distinctly different elemental composition

- Layers ‘cut’ differently due to differences in their mechanical properties

Most polymers are comprised of carbon, hydrogen, oxygen, and nitrogen. If the layers are composed of polyolefin(s) (carbon-based), individual layers will be difficult to differentiate by SEM imaging since they will have a similar grayscale in backscatter electron mode. Polymers such as FEP, PTFE, and PVDF will have a lighter contrast (lighter grayscale) compared to polyolefins due to the presence of fluorine, a higher atomic number element. Nylon and EVOH materials contain oxygen in their backbones, thus they will show contrast relative to polyolefins or halogen-containing polymers.

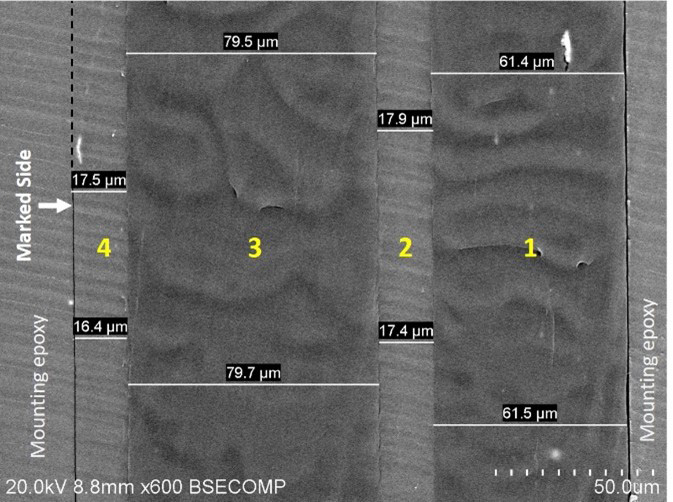

Figure 1 shows an SEM image of a film cross-section that was prepared by mounting a film piece in epoxy and cutting with a microtome to create a relatively flat/smooth surface. Four distinct layers were observed based on differences in electron density. Energy dispersive spectroscopy (EDS) was performed to confirm that the darker layers contained primarily carbon, the lighter layers contained carbon and oxygen, and layer 4 also contained nitrogen.

Would you like to learn more about multilayer packaging film characterization?

Please complete the form below to have an EAG expert contact you.