Low Parasitic HBM Testing

Home » Low Parasitic HBM Testing

The Human Body Model (HBM) Electrostatic Discharge (ESD) test is the oldest and most widely used ESD test in the electronics industry. The JEDEC HBM test isn’t static; it has been revised to keep up with the rapid changes in the semiconductor industry.

The latest revision of the spec addresses failures that are caused by parasitic impedances in HBM testers. EAG has the equipment and expertise to help you solve your HBM test problems.

EVOLUTION OF THE HBM SPEC

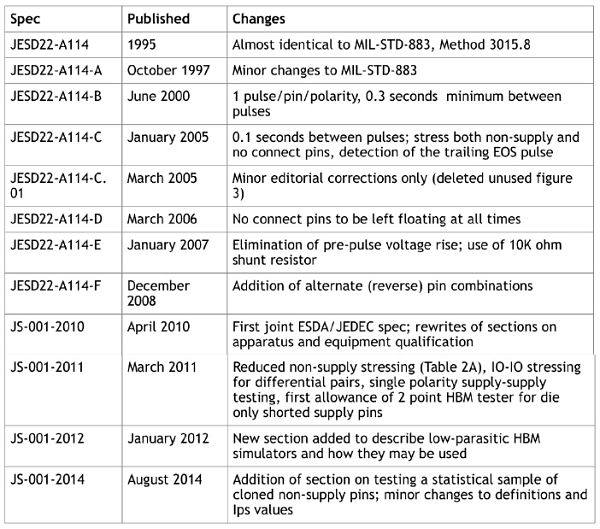

The current ANSI/ESDA/JEDEC HBM test, JS-001-2014, evolved from the military ESD testing spec, MIL-STD-883, Method 3017.8. The first JEDEC version of the spec was published in 1995. Over the last twenty years, incremental improvements have been made to the HBM spec based on the data and analysis performed by reliability engineers from a cross-section of the IC industry.

One of the main goals has been the reduction of the cost and time required for HBM testing. Other changes have addressed issues with the HBM simulator hardware. Table 1 summarizes the different revisions of the HBM spec.

IDEALIZED MODEL OF THE HBM TESTER

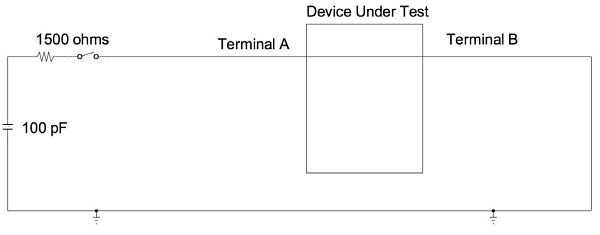

An idealized model of an HBM tester is shown in Figure 1.

In this model, a 100pF capacitor is charged with a high voltage power supply, not shown in the diagram. The supply is removed from the circuit, and the capacitor is discharged through a 1500Ω resistor. In this case, the device under test is the simplest one possible: a piece of wire. If you measure the current through the piece of wire as a function of time, the waveform looks like the one shown in Figure 2.

A MORE REALISTIC MODEL OF THE HBM TESTER

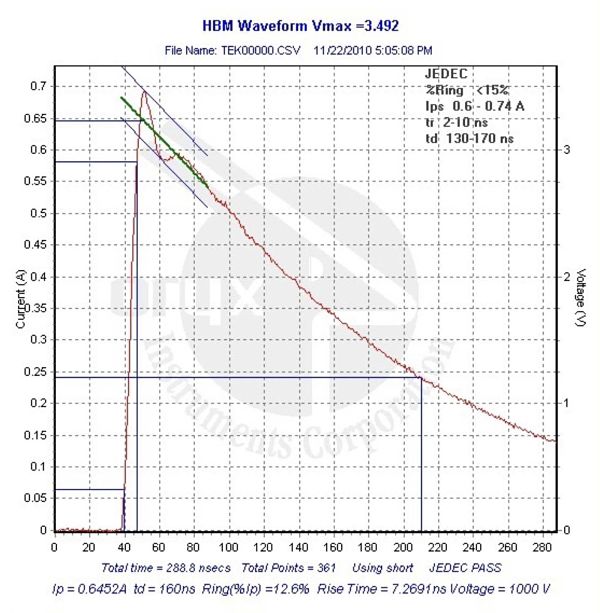

The waveform in Figure 2 shows some ringing, suggesting that there are parasitic impedances in the circuit. Parasitic impedances are any combination of extra unwanted passive devices (resistors, capacitors and inductors) in the signal path. For the discharge of an HBM simulator through a piece of wire, a more realistic circuit is shown in Figure 3.

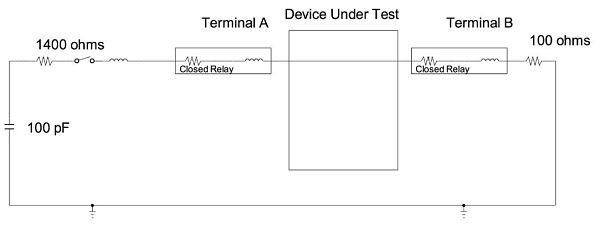

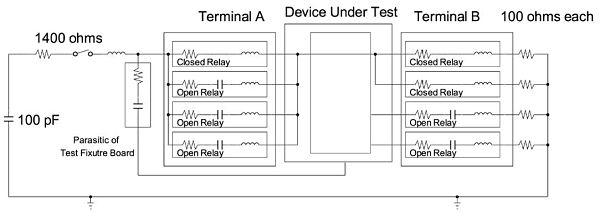

Because relays are used to connect the terminals of the device under test (DUT) to the HBM tester, parasitic inductance and resistance is added to the discharge path. In real HBM simulators, the 1500Ω resistor is distributed, with approximately 1400Ω on the Terminal A side and 100Ω on the Terminal B side. The resistance is divided in order to provide an in-spec waveform across the entire relay array.

Because most IC devices have more than two terminals, the situation is more complicated. Every pin on the device has a capacitively-coupled impedance path to the HBM simulator, whether the pin is connected or not. When one pin of a multi-pin power or ground group is stressed, the other pins in that group are floated, and they add additional capacitance, on the order of 4-8pF per pin. This extra capacitance can significantly change the shape of the waveform. In addition, the DUT board and socket also add additional resistance, inductance, and capacitance, causing additional changes to the HBM waveform. Any circuitry that is sensitive to the waveform slope or to the Terminal B resistance can be affected by parasitic impedances. It is even possible to damage non-stressed pins during HBM testing because of capacitive coupling. All of these can impact the waveform and cause false HBM failures (See Reference 6.) An even more realistic model of the HBM tester is shown in Figure 4.

A REDUCED PARASITIC HBM TESTER

To address the problems that have been seen with relay-based systems, the last three versions of the ESDA/JEDEC HBM test allow the use of a low parasitic HBM tester. The interface between the tester and the DUT is a probe station; the part is electrically connected at two points only. No special fixtures or sockets are required, and there is no relay array resulting in reduced parasitic impedance. The DUT can be a packaged part or a wafer. Critical structures can be characterized earlier in the design cycle. (See Figure 5.)

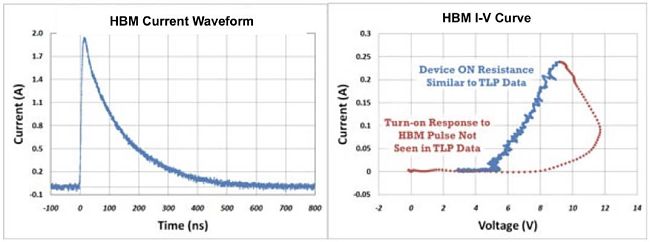

The low parasitic tester provides a highly accurate and nearly perfect HBM pulse. Voltage vs time and Current vs. Time can be measured while the pulse is being applied to the DUT. This allows a more thorough analysis of the DUT’s behavior during the HBM stress. (See Figure 6.)

EAG’S TWO POINT TESTER APPROACH

Because a two point tester is still too slow to do tests on large production parts, EAG has adopted a hybrid test strategy, using the available relay testers.

1. Test the DUT on a relay tester. This is allowed by the spec, and it’s the highest speed and lowest cost solution.

2. Minimize tester parasitic impedances by using the following practices:

- When a multi-pin supply or ground plane is Terminal B (grounded terminal), tie all of the pins to ground.

- When a multi-pin supply, ground, or non-supply group is Terminal A (zapped terminal), don’t zap all pins; zap a representative pin instead.

- In the supply/ground to supply/ground tests, zap positive polarity only.

3. If there are no failures at ATE, the DUT has passed the test.

4. If failures are observed or if characterization data is required:

- Do further stressing to identify and isolate the failing pin pairs.

- If a pin pair passes on the two-point tester, the device passes.

- If a pin pair fails, use the two-point tester to characterize the failure.

CONCLUSION

With the rapid changes in process technology, false failures due to relay tester parasitic impedances has become a more important HBM issue. EAG’s testing approach minimizes the incidence of false failures.

EAG has the capability to determine if you have a false failure using a two-point tester. This leads to fewer mask changes and faster time to market for EAG customers. You can count on EAG to provide you with the latest standards and best testing practices available in the industry.

REFERENCES

- JEDEC JESD22-A114, “Electrostatic Discharge (ESD) Sensitivity Testing Human Body Model (HBM),” (Other revisions were A, B, C, D, E.)

- ANSI/ESDA/JEDEC JS-001-2014, “Electrostatic Discharge (ESD) Sensitivity Testing Human Body Model (HBM),” (Other revisions were 2010, 2011, 2012.)

- E.Grund, M. Hernandez, Oryx Instruments, “Methods to Remove Anomalies from Human Body Model Pulse Generators,” EOS/ESDA Symposium 2006

- Evan Grund, Grund Technical Solutions LLC, “Two-Pin Human Body Model Testing,” EOS/ESDA Symposium 2009

- Scott Ward, Keith Burgess, Joe Schichl, Charvaka Duvvury, Peter Koeppen, Hans Kunz, Texas Instruments; Evan Grund, Grund Technical Solutions, “Overcoming the Unselected Pin Relay Capacitance HBM Tester Artifact with Two Pin HBM Testing,” EOS/ESDA Symposium 2010

- Yue Zu, Liang Wang, Rajkumar Sankaralingam, Scott Ward, Joe Schichl, Texas Instruments; “Threshold Voltage Shift due to Incidental Pulse on Nonstressed Pins during HBM Testing,” EOS/ESDA Symposium 2014

Would you like to learn more about Low Parasitic HBM Testing?

Contact us today for your Low Parasitic HBM Testing needs. Please complete the form below to have an EAG expert contact you.