FTIR and Contact Angle Measurements of Surface Modified Polymers

Home » FTIR and Contact Angle Measurements of Surface Modified Polymers

Polymer materials are ubiquitous in medical devices, automobiles, electronics, food packaging and in a wide range of other industrial and consumer products. The surfaces of these materials can be modified to harden the surface, reduce or increase the surface reactivity and alter the surface roughness, etc.

A common surface modification method involves using plasma to etch the surface or to introduce custom functionality to the surface. The modification may be performed for many reasons but it typically needs to impart a specific functional group and be free from contamination. The surface of the sample is altered when a plasma creates energetic species that react with the polymer surface to produce volatile compounds, thereby removing and/or adding molecules to/from the surface.

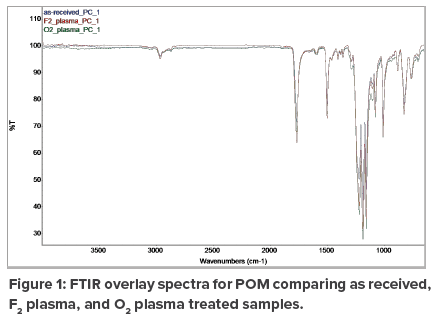

The use of different types of plasma such as oxygen- or fluorine-based plasmas can generate new chemical species on the surface of the polymer and hence change its surface properties.

Fourier Transform Infrared Spectroscopy (FTIR) is a well-established analytical technique for characterizing organic and some inorganic materials. FTIR provides chemical bonding information by exciting a material with infrared radiation and measuring the resulting absorption or transmission spectrum. FTIR can be used to monitor changes in the surface composition due to plasma exposure. Similarly, dynamic contact angle tensiometry provides information about the wettability of the surface by measuring the interaction between a solid surface and a liquid. The combination of two techniques can be useful for gaining a better understanding of the effect of the specific plasma treatment.

Would you like to learn more about Measurements of Surface Modified Polymers?

Contact us today for your measurement of surface modified polymer needs. Please complete the form below to have an EAG expert contact you.