Failure Analysis of Metals, Nonmetals & Composites

Home » Failure Analysis of Metals, Nonmetals & Composites

EAG Laboratories is a full service laboratory providing a comprehensive array of analytical equipment in a modern facility for failure analysis and problem solving. As a result of the increasing sophistication of technology, the analytical techniques used in the past can no longer answer many of the problems today.

Constantly improving its analytical equipment, coupled with developing new techniques, EAG adds a new dimension to its problem solving capability unparallel in the industry.

Failure analysis and product improvement of metal components has been a highlight at EAG for over fifty years.

Applications including aircraft, aerospace, transportation, construction, consumer products, electronics, hostile service environments, energy production, structural components and medical devices are just a few EAG has been involved in over the years.

Materials selection based on your engineering specifications for products made of metals, alloys, plastics, polymers or composites is one of our many specialties.

Typical Techniques

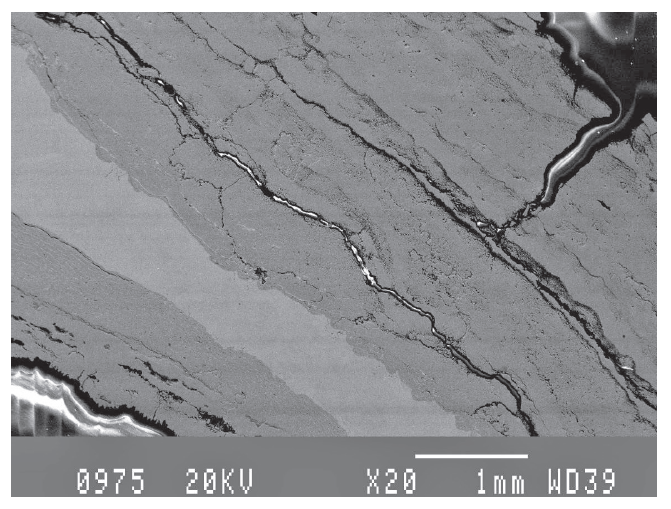

- Scanning Electron Microscopy

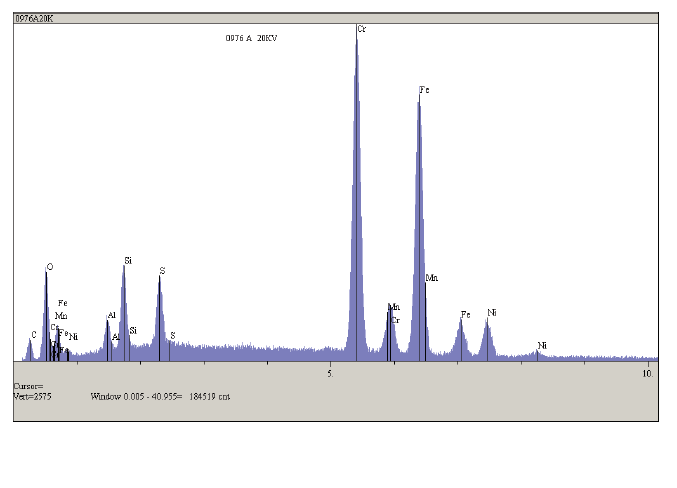

- Electron Microprobe Analysis

- AUGER/ESCA Analysis

- Fourier Transform Infra-Red Spectroscopy

- DSC/TGA Analysis

- X-Ray Radiography

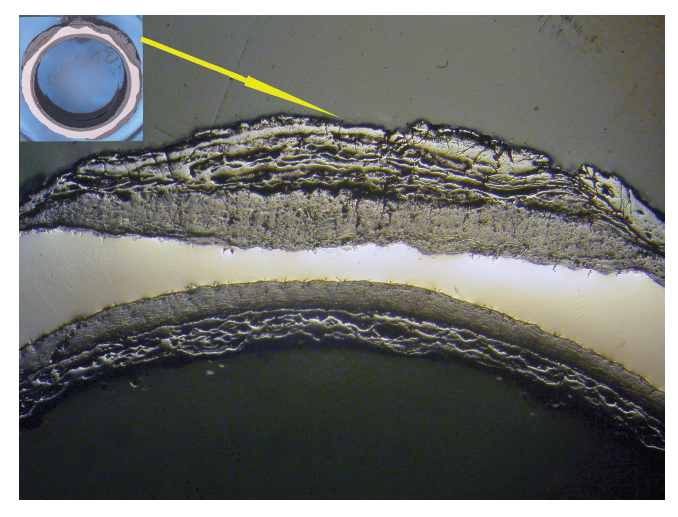

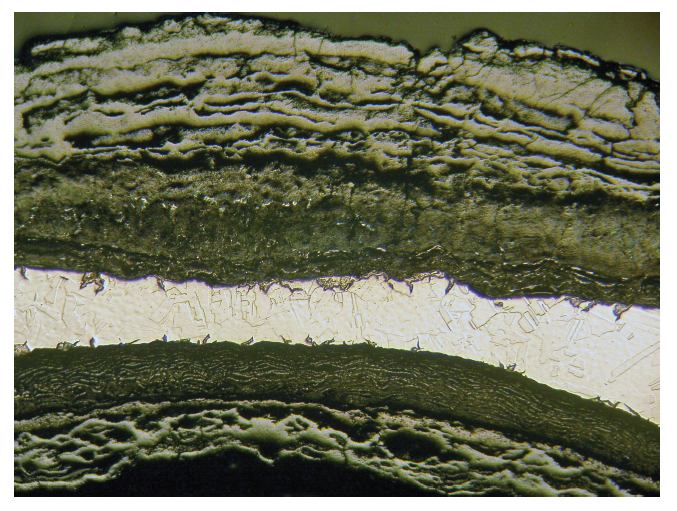

- Metallographic Examination

- Hardness and Microhardness Testing

- Chemical Analysis and Mechanical Testing

Typical Detections

- Fracture and Failure Modes and Origins

- Fatigue and Other Slow Crack Growth Mechanisms

- Brittle and Ductile Overload Failures

- Stress Corrosion and Hydrogen Embrittlement Failures

- Corrosion/Oxidation Problems

- Contamination Problems

- Wear Failures

- Heat Treatment Problems

- Design/Stress Related Failures

- Plating Problems

Would you like to learn more about Failure Analysis of Metals?

Contact us today for your failure analysis of Metals, Nonmetals & Composites needs. Please complete the form below to have an EAG expert contact you.