Characterization of Surface Aluminum Contamination on Processed Silicon Wafers

Home » Characterization of Surface Aluminum Contamination on Processed Silicon Wafers

Eliminating or reducing Al and other metal surface contamination on silicon wafers is a very critical part of IC processes. Choosing an appropriate measurement technique is important for providing accurate and consistent results. The present application note highlights some important advantages of using SurfaceSIMS.XP (XP = extended profile) to determine surface Al contamination on processed Si wafers.

SurfaceSIMS is an ASTM approved method for measuring Na, Al, K and Fe contamination on silicon substrates (ASTM F 1617). On bare Si wafers, SurfaceSIMS provides very similar results over several measurement decades, comparable to other surface metal contamination measurement techniques such as TOF-SIMS and VPD-based techniques. SurfaceSIMS results are reported as contaminant areal densities (atoms/cm2).

SurfaceSIMS.XP is an extension of the SurfaceSIMS method where the same analytical conditions are used, but data is reported in the form of a complete SIMS depth profile. It not only provides surface areal densities (atoms/cm2), but also detects any non-silicon residual film covering a processed wafer.

When processed wafers are covered with a thin residue other than native Si oxide, TOF-SIMS and VPD-based techniques may not be suitable methods for contamination measurement. These methods will provide incorrect results if the metal contaminants are buried and analyses are terminated too early (TOF-SIMS) or if recovery yields are too low due to inappropriate extraction chemistry (VPD). However, since SurfaceSIMS.XP is a depth profiling technique, it has distinct advantages in certain cases, and should be the method of choice for the analysis of many processed Si wafers.

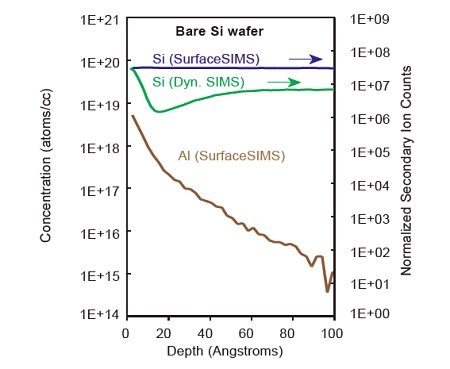

Figure 1 shows the Al contamination on a bare silicon wafer measured with SurfaceSIMS.XP. Si is also measured with SurfaceSIMS.XP and conventional dynamic SIMS. The Si profile measured with dynamic SIMS shows the presence of a native oxide on the Si surface as seen in the SIMS surface transient region. The flat Si profile obtained by SurfaceSIMS. XP shows that the transient effect is eliminated by oxygen flooding which maintains surface oxidation despite sputtering.

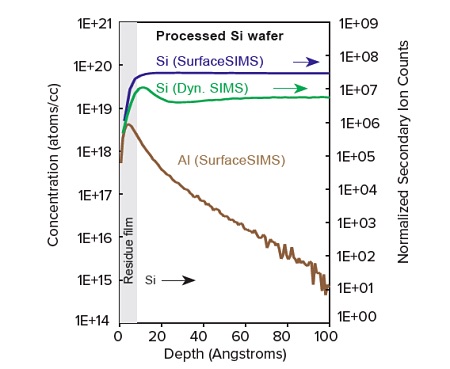

Figure 2 shows Al contamination on a processed silicon wafer. The Si profile indicates the presence of a thin residual layer on the silicon surface. Al appears to be at the interface instead of the top surface. Incomplete oxidation of the buried Si surface is observed by the temporary increase in the Si count rate in the dynamic SIMS profile. For such processed samples, only SurfaceSIMS.XP will be able to provide accurate and consistent contamination measurements.

Would you like to learn more about Surface Aluminum Contamination?

Contact us today for your characterization of surface Aluminum contamination needs. Please complete the form below to have an EAG expert contact you.